Needle beam type inverted arch lining sliding framework and construction method thereof

A construction method and a needle beam technology are applied to the needle beam type inverted arch lining sliding formwork and the construction field thereof, which can solve the problems of high labor cost and low construction efficiency, and achieve the effects of high work efficiency, fast lining cycle and safety assurance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

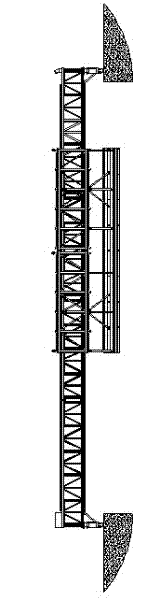

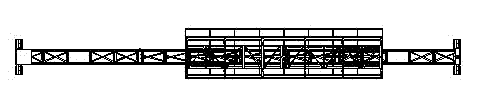

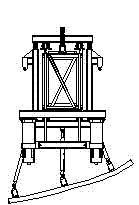

[0036] Embodiment of the present invention: used in Gaogao Tunnel of Guizhou-Guangzhou Railway, needle beam type inverted arch lining sliding formwork structure such as Figure 1 to Figure 5 As shown, it includes needle beam assembly 1, needle beam leg assembly 2 at both ends of needle beam assembly 1, needle beam frame assembly 3 in the middle of needle beam assembly 1, needle beam frame assembly The bottom of 3 is connected to the inverted arch template 4; on the needle beam frame assembly 3, there is also a walking device 5.

[0037] The needle beam assembly 1 is provided with a steering pulley 1-1, a winch installation position 1-2, and a track 1-3.

[0038] Supporting roller 3-1 and electric hoist support 3-2 are arranged on needle beam frame assembly 3.

[0039] Traveling device 5 comprises power supply control cabinet, winch, traction wire rope and pulley.

[0040] Between the inverted arch template 4 and the needle beam frame assembly 3, a hinge seat 6-1 and a screw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com