Smoke collecting device of iron tapping hole of rotary electric furnace

A flue gas capture and tap hole technology, which is applied to lighting and heating equipment, furnaces, and smoke removal, etc., can solve the difficulties in the design and arrangement of the exhaust hood of the tap hole of the rotary electric furnace, and the difficulty in the arrangement of the trap hood and the piping. , Increase the difficulty of collecting the hood at the tap hole and other problems, so as to achieve the effect of solving the difficulty of flue gas collection, large market value and prolonging the residence time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

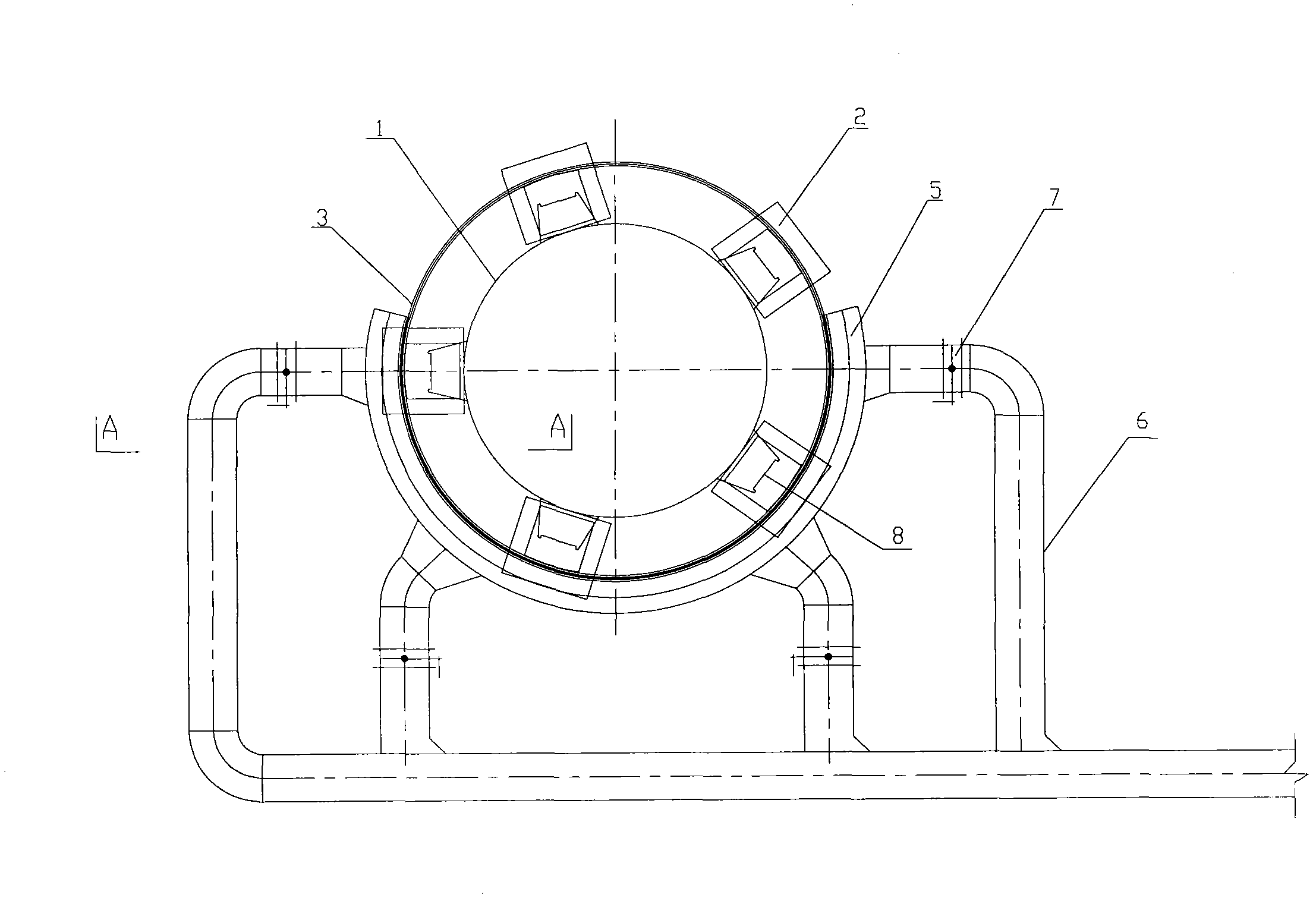

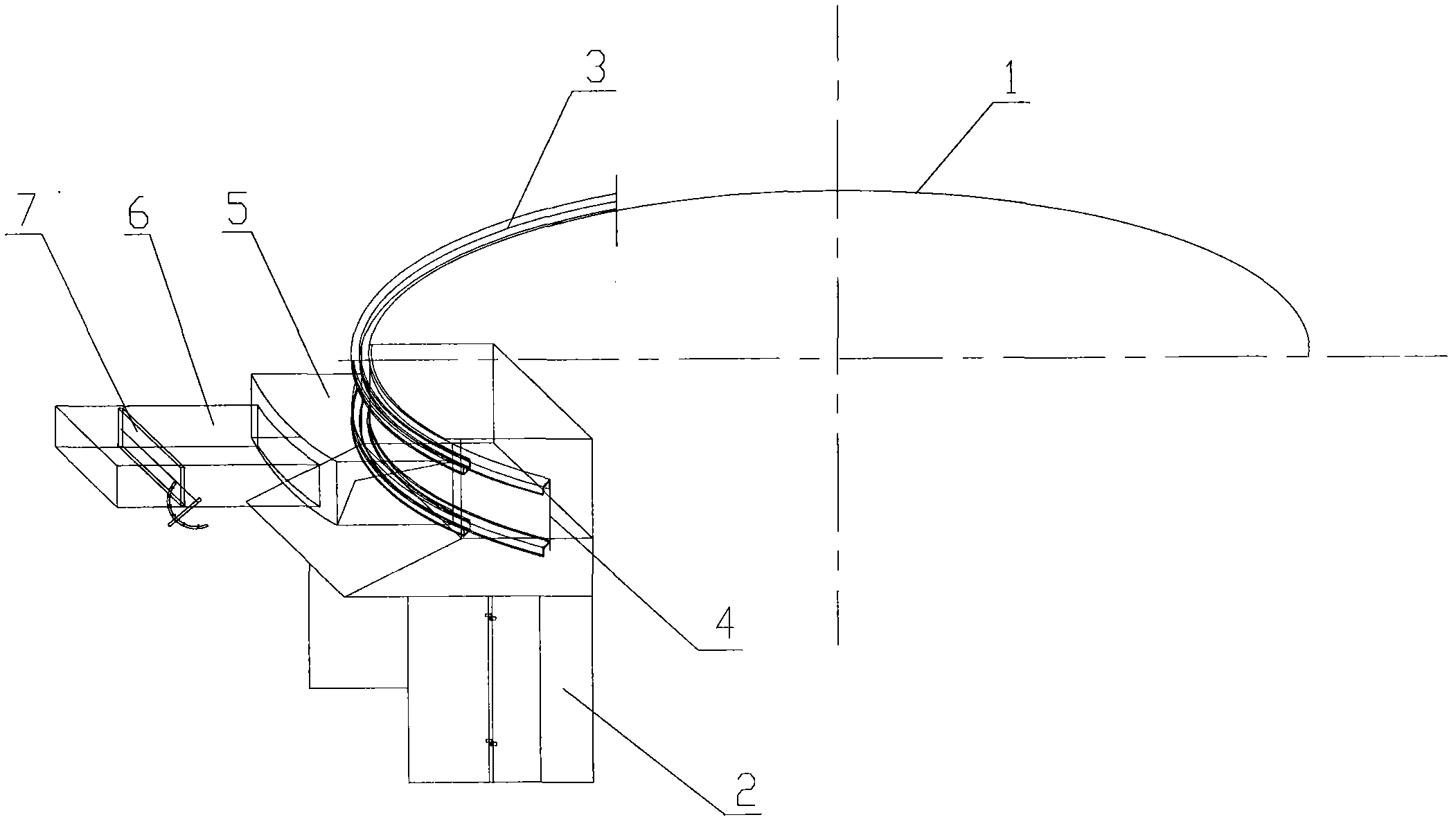

[0022] In order to better understand the purpose, structure and function of the present invention, a kind of rotary electric furnace taphole flue gas collection device of the present invention will be further described in detail in conjunction with the accompanying drawings.

[0023] like figure 1 , 5 As shown, the rotary electric furnace of the present invention is provided with several tapholes 8, and the tapholes 8 are evenly distributed on the circumference of the furnace body of the electric furnace 1, and the molten iron smelted in the electric furnace 1 flows out from the tapholes 8, and passes through the molten iron Packet 10 is received for reprocessing. The fume collecting hood 2 in the flue gas collection device for the taphole of the rotary electric furnace of the present invention is arranged around the taphole 8 and corresponds to the taphole 8 on the 1 circle of the electric furnace one by one.

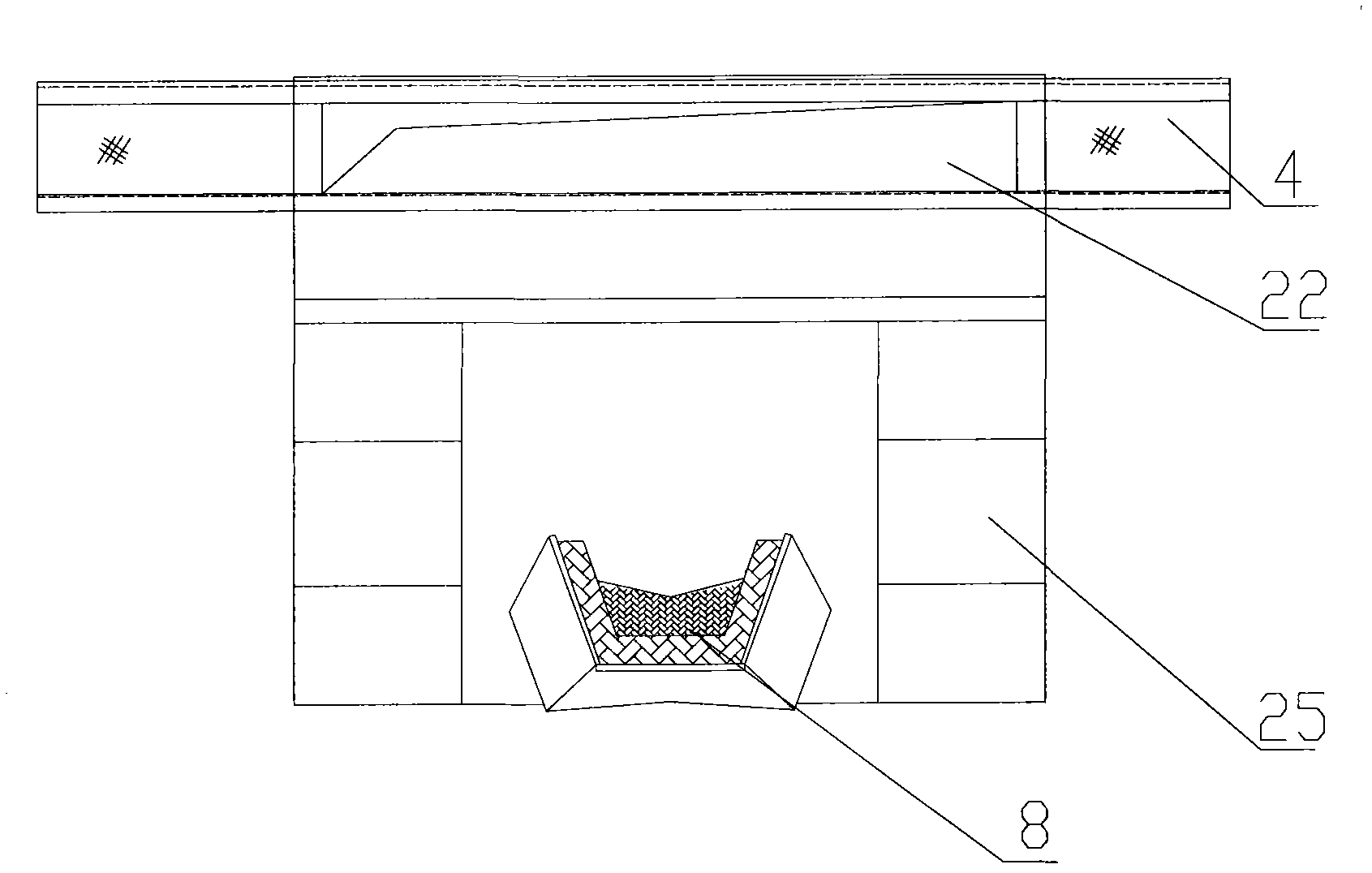

[0024] like image 3 and Figure 4 As shown, the fume collect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com