LCD device and manufacture method thereof

A technology of a liquid crystal display device and a manufacturing method, which is applied in the directions of liquid crystal materials, chemical instruments and methods, optics, etc., can solve the problems of high manufacturing cost and poor alignment stability, and achieves low price, good process stability, and reduced manufacturing costs. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The detailed description and technical content of the liquid crystal display device of the present invention and its manufacturing method are as follows with regard to the accompanying drawings:

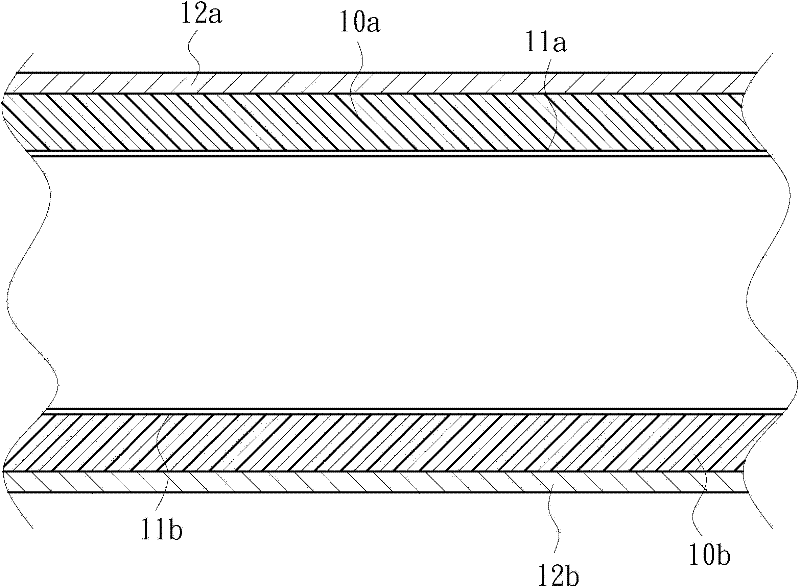

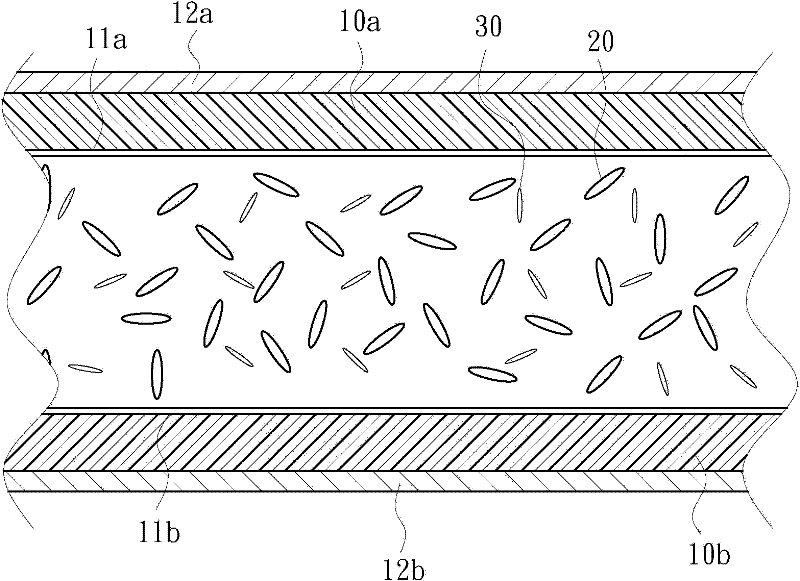

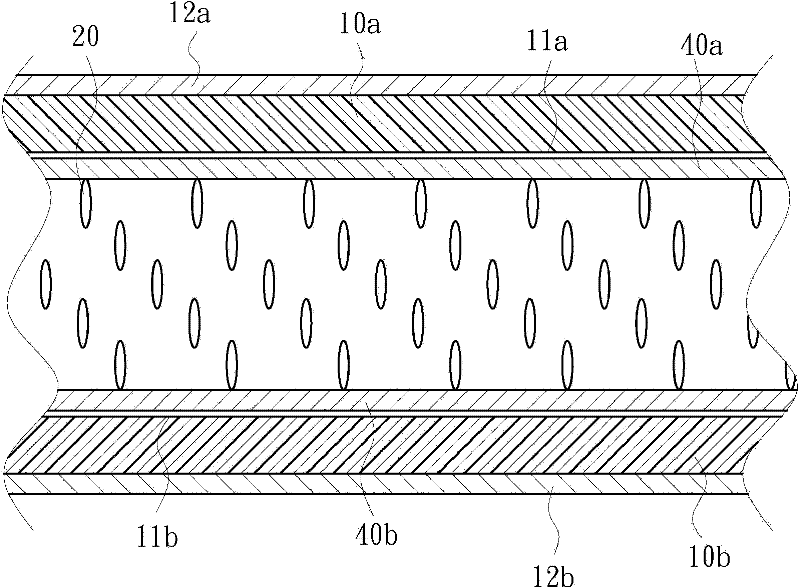

[0047] refer to Figure 1-1 to Figure 1-3 Firstly, a first substrate 10a and a second substrate 10b are provided, the surfaces of the first substrate 10a and the second substrate 10b respectively have a first electrode 11a and a second electrode 11b. The first substrate 10a and the second substrate 10b are arranged parallel to each other, so that the first electrode 11a and the second electrode 11b are opposite to each other, and between the first substrate 10a and the second substrate 10b A polarizing plate 12a, 12b is provided on the outer side of each, such as Picture 1-1 shown. The first substrate 10a and the second substrate 10b can be transparent materials such as inorganic glass or flexible plastic, such as quartz glass, soda-lime glass, borosilicate glass, low-alkali...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com