Preparation method of cyclic carbonates

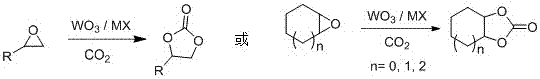

A technology of cyclic carbonate and carbon dioxide, applied in the field of preparation of cyclic carbonate, can solve the problems of high temperature, high reaction pressure, high toxicity of acetonitrile, etc., and achieve the effects of less species, low reaction temperature and pressure, and large adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A kind of preparation method of cyclocarbonate, utilize epoxy compound and carbon dioxide as reactant, with the WO with oxygen hole 3 For catalyst, comprising the following steps:

[0036] Add 100 mg of WO with oxygen vacancies to the reaction kettle 3 Catalyst, 10 mg tetrabutylammonium bromide, 0.8 mL propylene oxide, and then use carbon dioxide to replace the gas three times. Under the condition of 1.0 MPa carbon dioxide atmosphere and 30 °C, the reaction was stirred for 10 h, and the reaction mixture was passed through a tube about 1 cm long. Silica gel chromatography column to remove the catalyst, that is. Reaction conversion rate 95%, selectivity 99%, 1H NMR (400 MHz, CDCl 3 ): δ 1.50 (d, 3H); 4.03 (t, 1H); 4.56 (t, 1H); 4.84 (m, 1H).

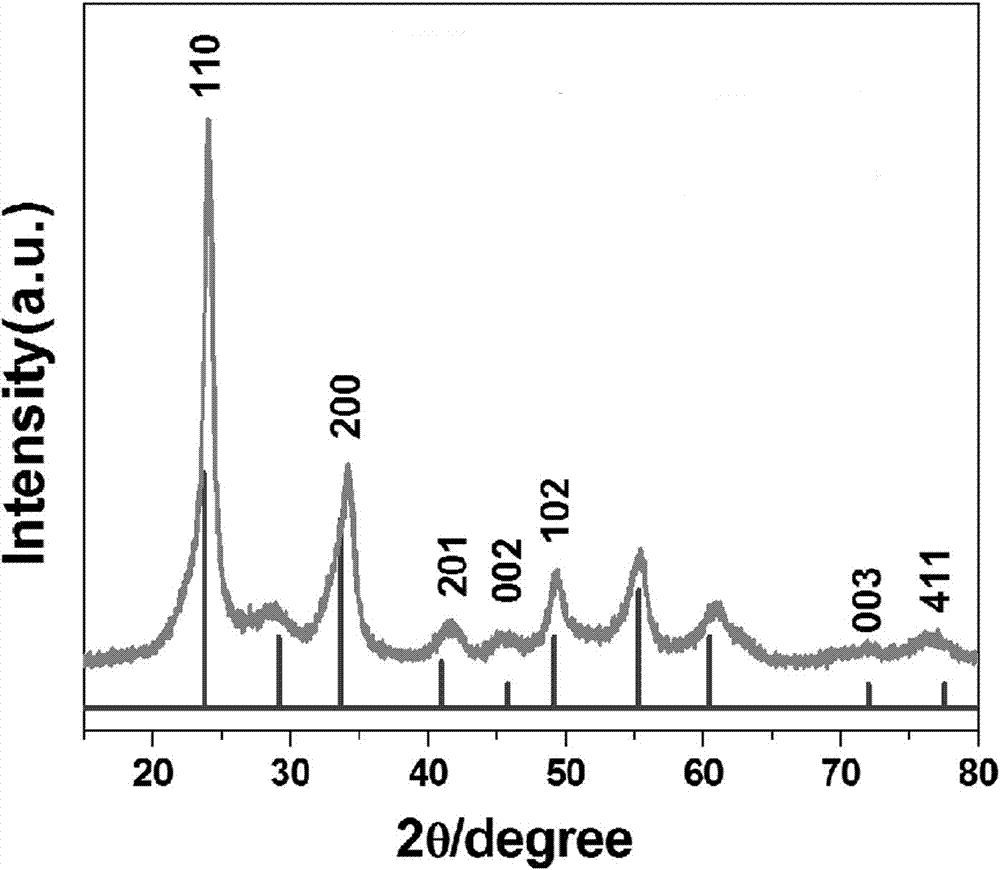

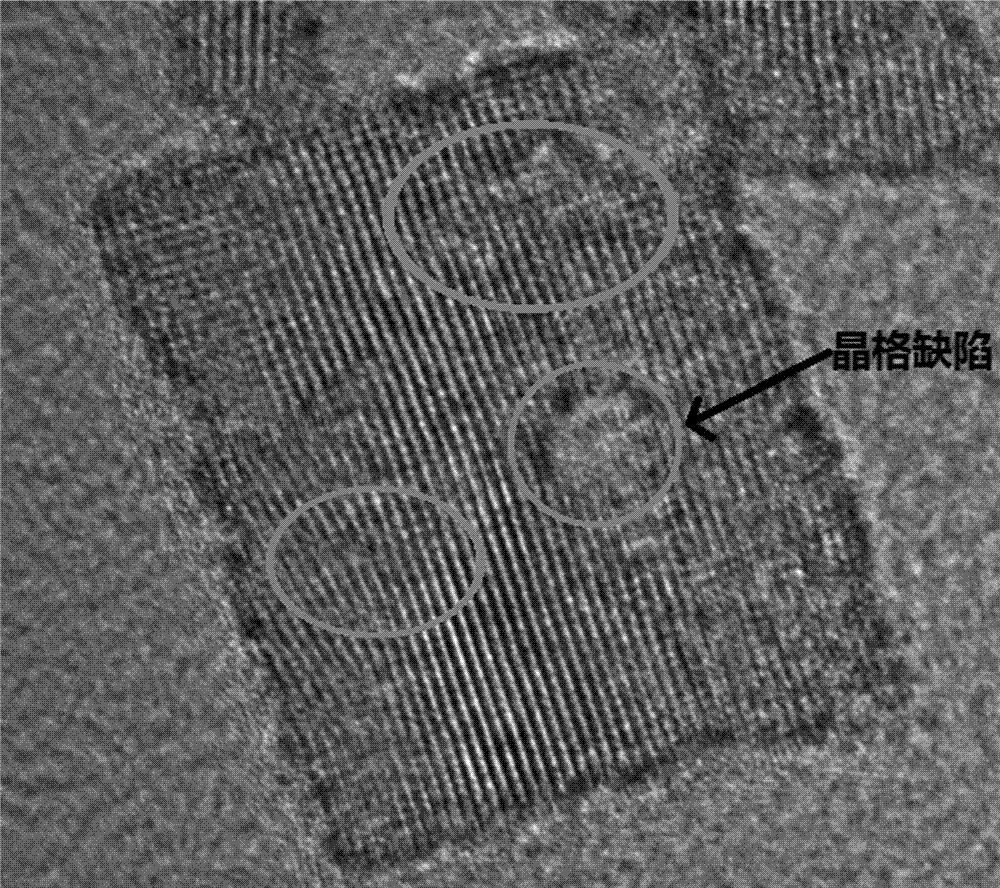

[0037] Among them, the WO with oxygen vacancies 3 The preparation method of catalyst comprises the following steps:

[0038] Put 0.5 g of yellow tungsten oxide nanosheets (average thickness 7 nm, average length 50 nm) in a t...

Embodiment 2

[0041] A kind of preparation method of cyclocarbonate, utilize epoxy compound and carbon dioxide as reactant, with the WO with oxygen hole 3 For catalyst, comprising the following steps:

[0042] Add 80 mg of WO with oxygen holes in the reaction kettle 3 Catalyst, 10mg tetrabutylammonium bromide, 2mL dichloromethane, 0.6mL epichlorohydrin, and then use carbon dioxide to replace the gas 3 times, under the condition of 0.3MPa carbon dioxide atmosphere and 50℃ temperature, stir the reaction for 8h, and the reaction mixture passes A silica gel chromatography column with a length of about 1 cm was used to remove the catalyst, and the reaction conversion rate was 96%, and the yield was 99%.

[0043] Among them, the WO with oxygen vacancies 3 The preparation method of the catalyst is shown in Example 1.

[0044] The WO with oxygen vacancies in Example 2 3 The catalyst can be recycled for 7 times, the conversion rate of the 7th time is 93%, and the selectivity is 96%.

Embodiment 3

[0046] A kind of preparation method of cyclocarbonate, utilize epoxy compound and carbon dioxide as reactant, with the WO with oxygen hole 3 For catalyst, comprising the following steps:

[0047] Add 30 mg of WO with oxygen vacancies to the reaction kettle 3 Catalyst, 10mg sodium bromide, 5mL tetrahydrofuran, 0.1mL tetradecane oxide, and then use carbon dioxide to replace the gas 4 times. Under the condition of 0.8 MPa carbon dioxide atmosphere and 80℃ temperature, stir the reaction for 5h, and the reaction mixture passes through a tube about 1 cm long Silica gel chromatography column to remove the catalyst, namely. The reaction conversion rate is 95%, and the yield is 98%.

[0048] Among them, the WO with oxygen vacancies 3 The preparation method of catalyst comprises the following steps:

[0049] Put 0.5g of yellow tungsten oxide nanorods (average diameter 200 nm) into the reaction bottle, add 30mL of water, ultrasonically disperse evenly, pass in a mixed atmosphere of h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com