Method for designing loading track for multi-pass roll bending of wall plate and generating numerical control code

A technology of numerical control code and loading trajectory, applied in the direction of computer control, program control, comprehensive factory control, etc., can solve the problem of inability to guarantee the accuracy of the shape of the formed parts, so as to improve the design efficiency, improve the pertinence and efficiency, and highlight the substantiality The effect of features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with a certain type of aircraft embodiment.

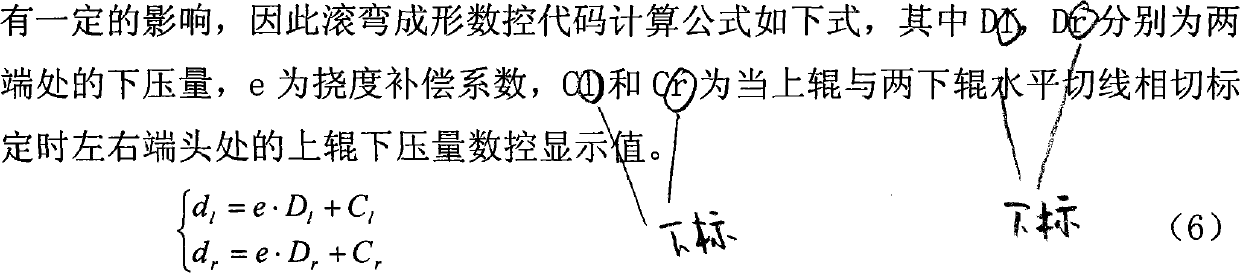

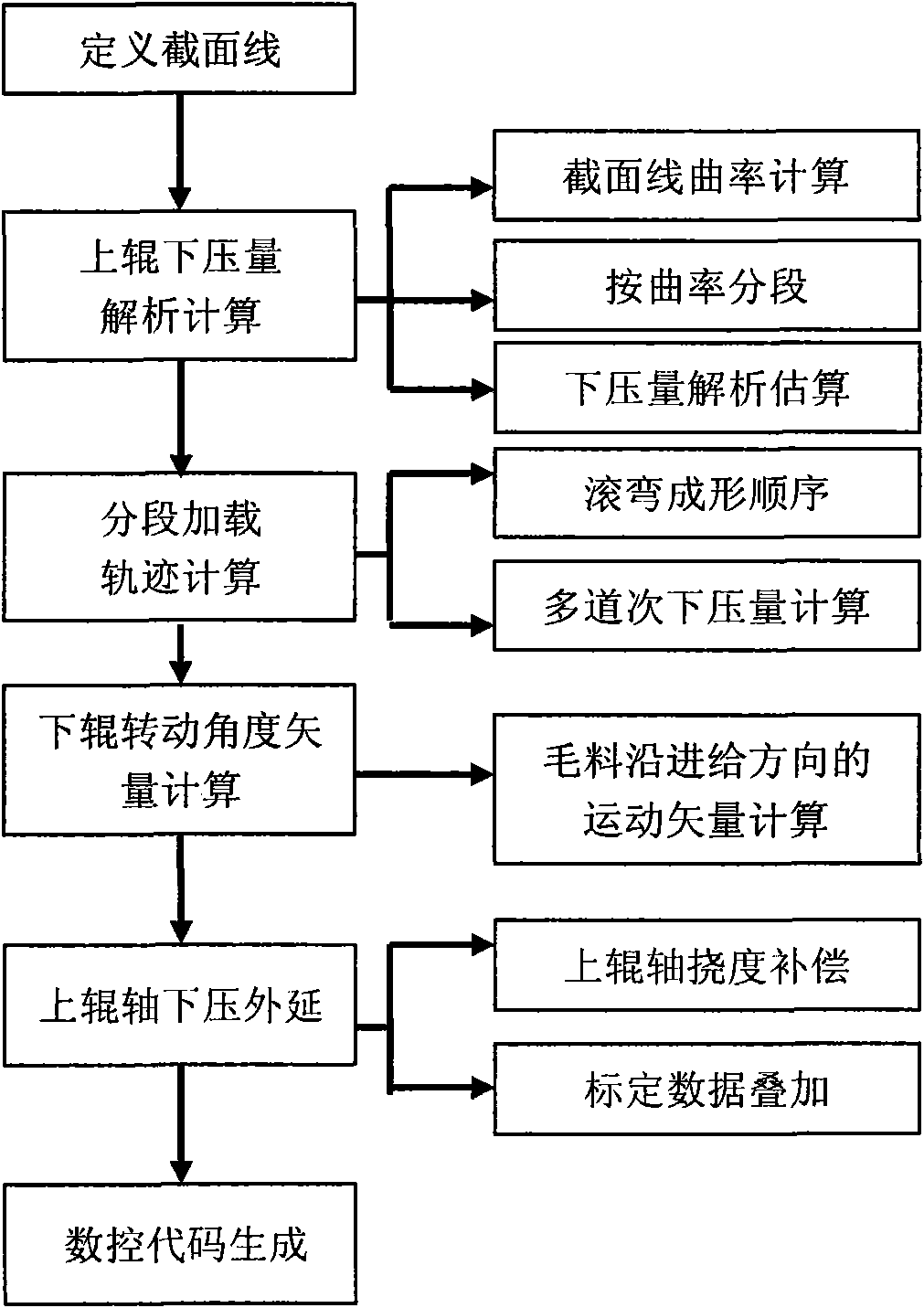

[0040] Figure 1 to Figure 7 and Figure 10 It shows a multi-pass rolling bending loading trajectory design and numerical control code generation method for wall panels based on the Jammes10008 CNC rolling bending machine. The specific implementation steps of the method are as follows:

[0041] Step 1: Calculation of the pressing force of the upper roller movement

[0042] It refers to the design of the pressing position of the two screw drive mechanisms on the left and right of the upper roll of the three-axis roll bender. The method of calculating the loading trajectory is the geometric analysis method of the sectional plane, and the specific method is:

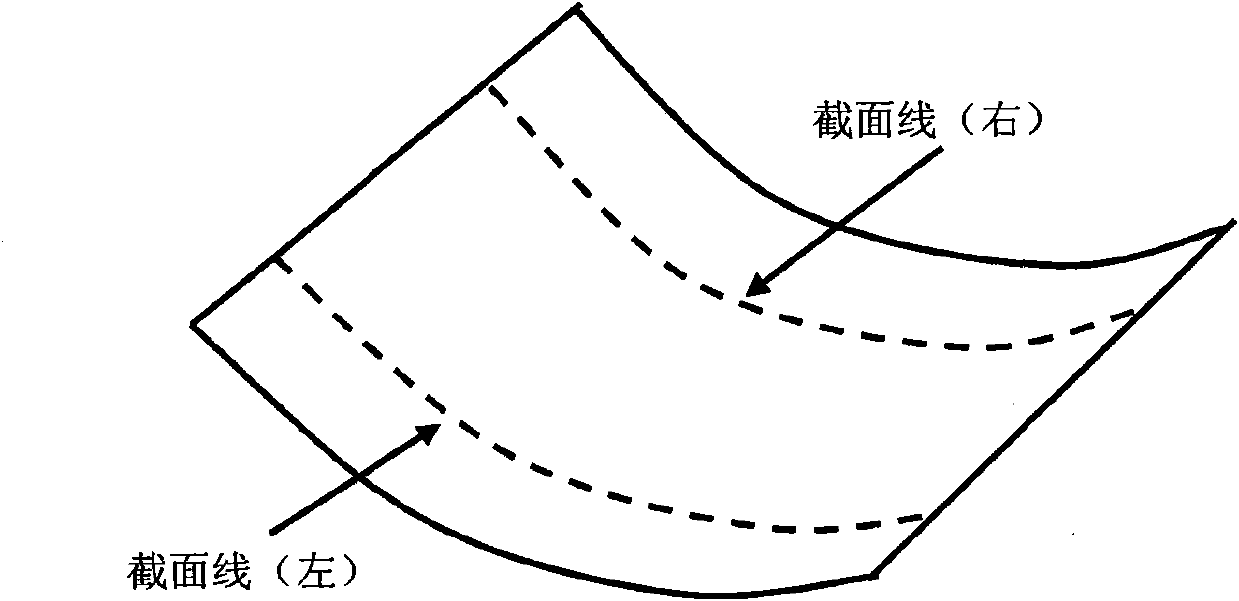

[0043] (1) Calculate the section line

[0044] According to the placement position of the parts on the lower roller, select two planes perpendicular to the lower roller, on the basis of the finite el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com