Housing of rotating motor

A technology for rotating electrical machines and housings, which is applied in the housing field of internally transformed rotating electrical machines, which can solve problems such as the difficulty in dissipating heat from the coils of the stator core, the lower overall cooling performance of the housing, and the difficulty in cooling the axial center of the stator core, etc., to achieve Improved cooling performance and improved thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

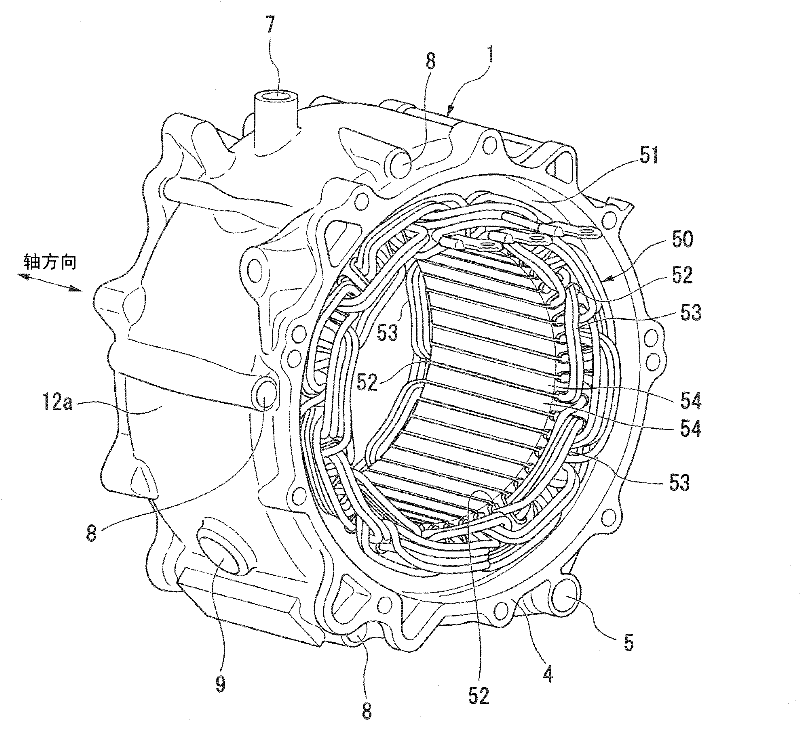

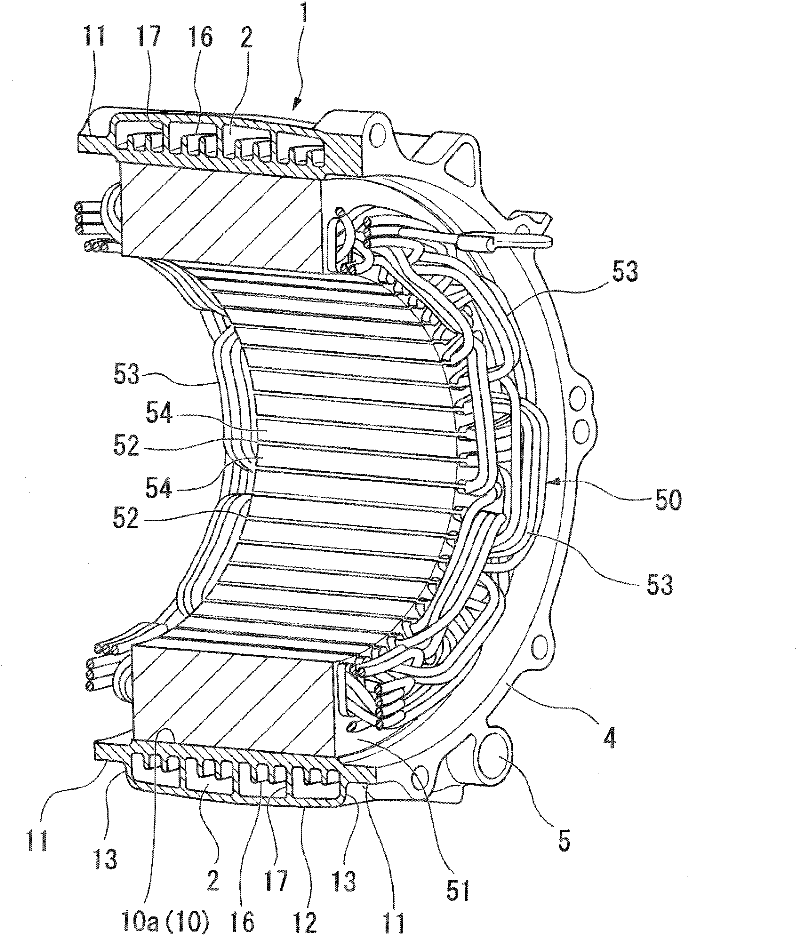

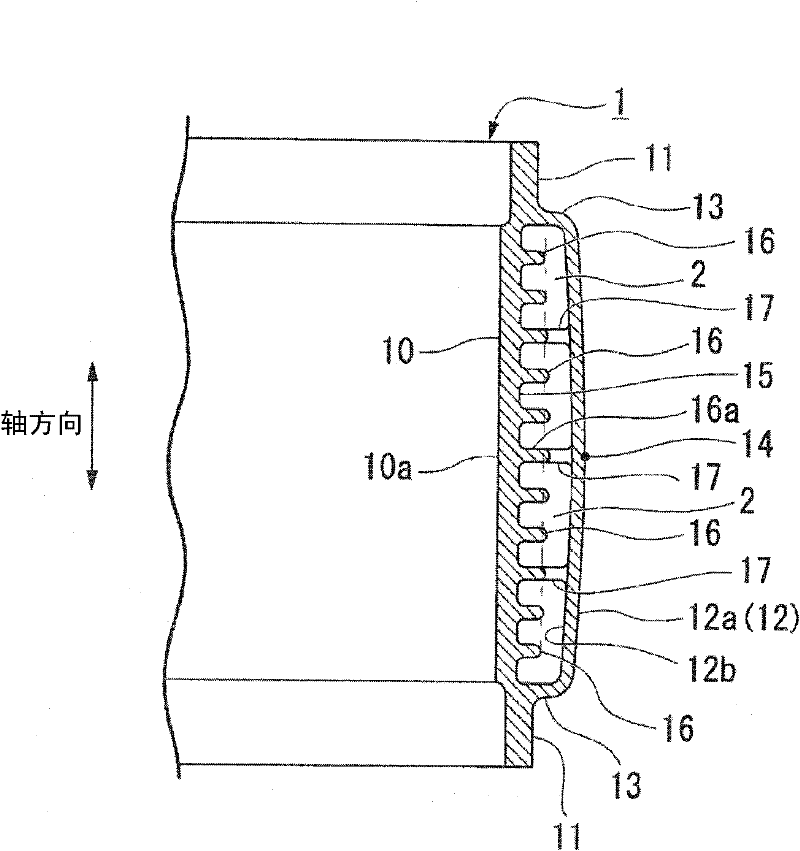

[0035] Below, refer to Figure 1 to Figure 4 , an embodiment of the casing of the rotating electrical machine according to the present invention will be described. It should be noted that the rotating electric machine in this embodiment is in the form of an electric motor.

[0036] exist figure 1 Among them, symbol 1 is a casing of an internal type motor (rotary electric machine), symbol 50 is a stator of the motor, and the stator 50 is fixed inside the casing 1 . That is, the housing 1 is disposed outside the stator 50 .

[0037] The stator 50 includes: a plurality of teeth 54 protruding radially inwardly in an annular stator core 51; a plurality of slots 52 formed between adjacent teeth 54, 54; Multiple coils 53 on slot 52 . A rotor (not shown) is disposed inside the stator 50 , and the rotor is rotated by passing a three-phase current through the coil 53 to generate a rotating magnetic field.

[0038] The housing 1 is made of aluminum and manufactured by aluminum casti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com