Transparent Conductive Laminated Film

A technology of transparent conductivity and laminated film, which is applied to the direction of conductive layer, coating, layered products, etc. The effect of reducing the reduction of visibility and suppressing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

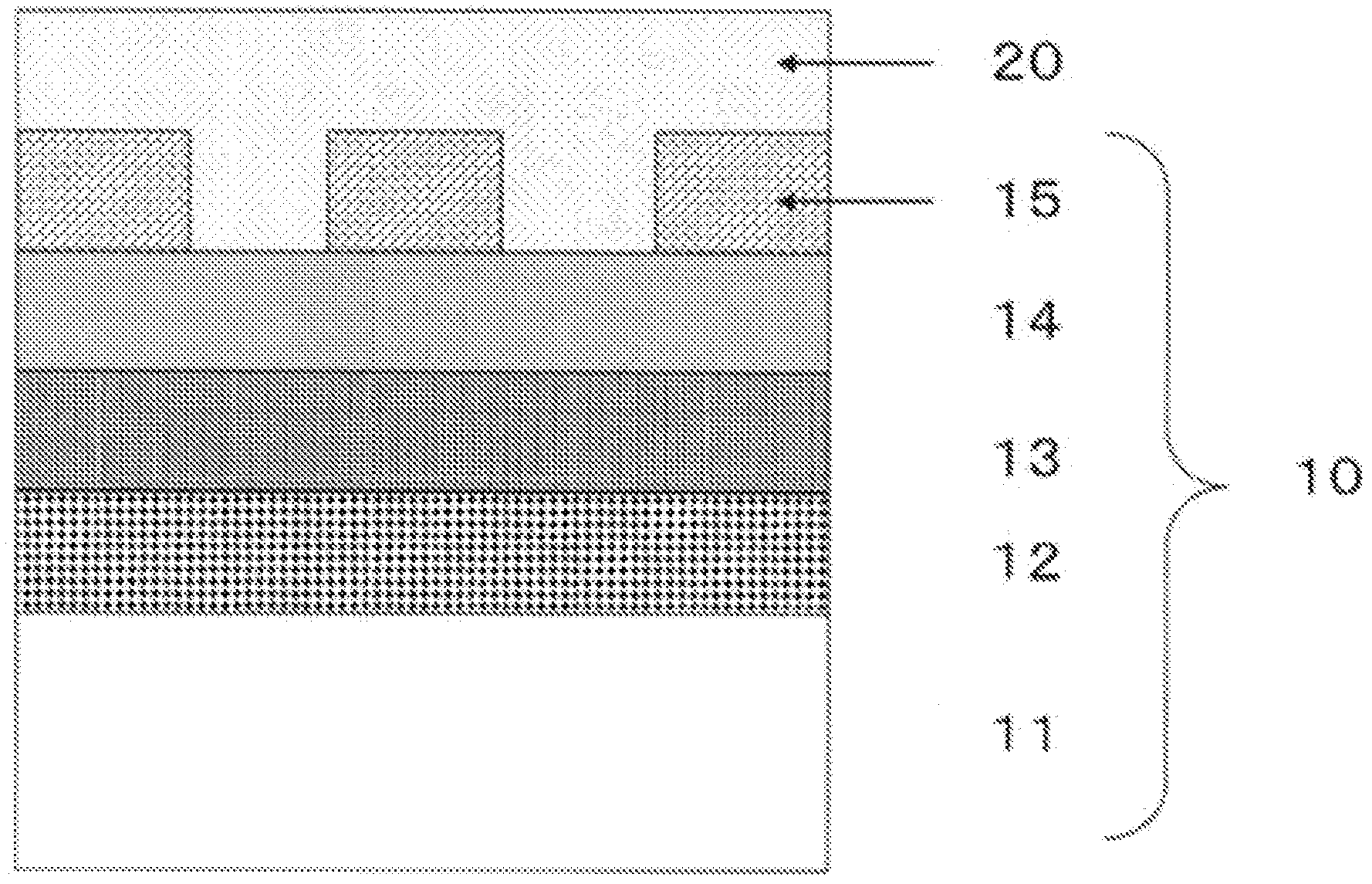

Method used

Image

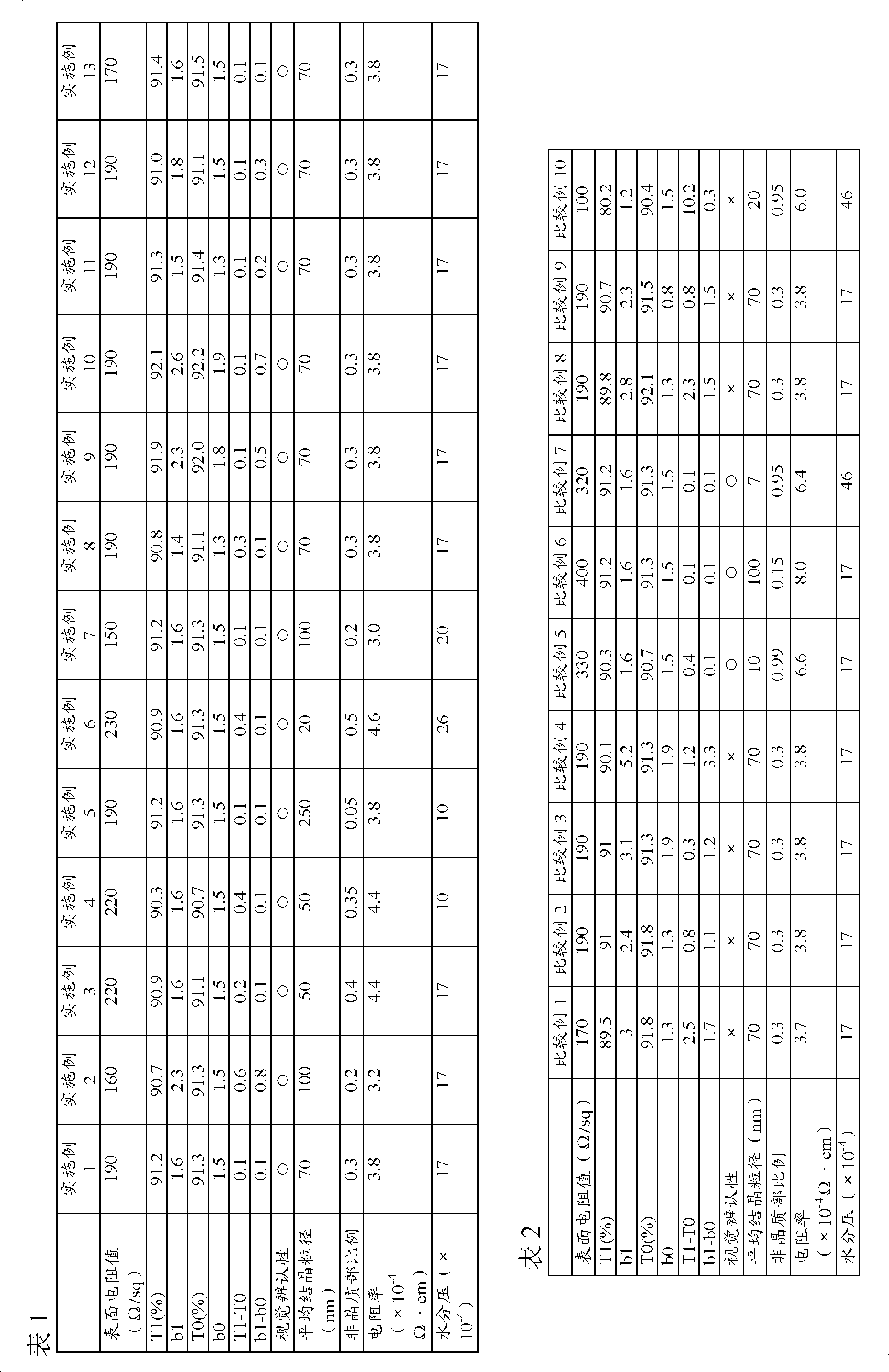

Examples

Embodiment 1

[0124] Add toluene / MEK (80 / 20: mass ratio) as a solvent to 100 parts by mass of an ultraviolet-curable acrylic (ester) resin (manufactured by Dainichi Seika Kogyo Co., Ltd., SEIKABIMU EXF-01J) containing a photopolymerization initiator and mix The solvent was adjusted to have a solid content concentration of 50% by mass, stirred and dissolved uniformly, and prepared as a coating liquid.

[0125] The prepared coating solution was applied to a biaxially oriented transparent PET film (manufactured by Toyobo Co., Ltd., A4300, thickness 100 μm) having an easy-adhesive layer on both sides with a Meyer Bar coater so that the thickness of the coating film was 5 μm. After drying at 80°C for 1 minute, irradiate ultraviolet rays (light intensity: 300mJ / cm2) with an ultraviolet irradiation device (manufactured by EYEGRAPHICS CO., LTD. 2 ) to cure the coating. Next, after preparing a coating film similarly to the opposite surface, it heated at 180 degreeC for 1 minute, and reduced the vol...

Embodiment 2

[0134] Except that the target material when forming a transparent conductive film was changed to indium oxide containing 1% by mass of tin oxide (manufactured by Sumitomo Metal Mining Co., Ltd., density 7.1g / cm 3 ) except that in the same manner as in Example 1, a transparent conductive laminated film was produced.

Embodiment 3

[0136] In addition to changing the target material when forming a transparent conductive film to indium oxide containing 5% by mass of tin oxide (manufactured by Sumitomo Metal Mining Co., Ltd., density 7.1g / cm 3 ) except that in the same manner as in Example 1, a transparent conductive laminated film was produced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com