Intelligent electric welding clamp workbench for body in white

A workbench and body-in-white technology, applied in resistance welding equipment, manufacturing tools, welding equipment, etc., can solve problems that cannot meet the requirements of electric welding clamping process, etc., and achieve practicability, convenient implementation, and universalization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

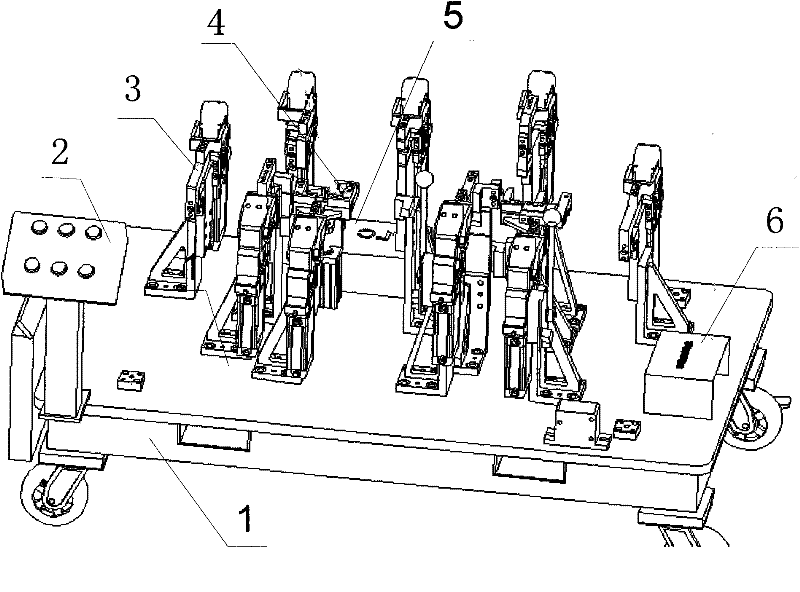

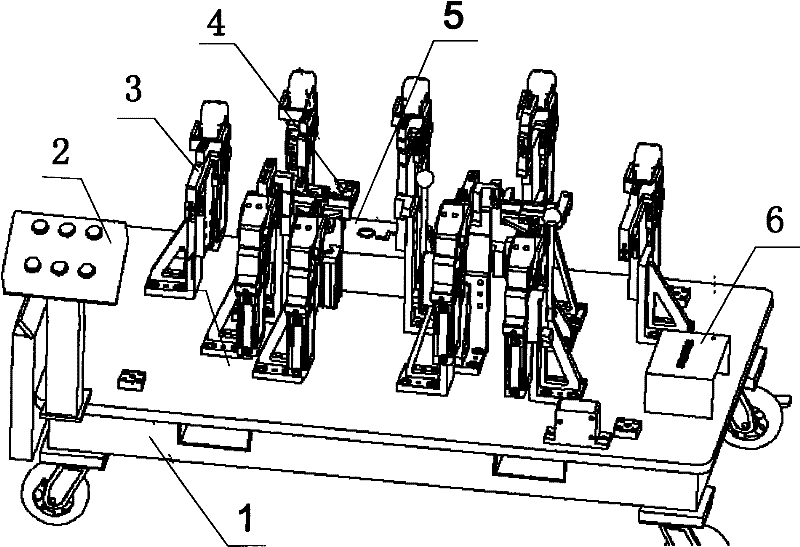

[0012] Such as figure 1 As shown, an intelligent electric welding fixture workbench for a body-in-white includes a base plate 1 , and an operating table 2 , an air pressure clamping device 3 and a control box 5 are arranged on the upper surface of the base plate 1 . The console 2 is electrically connected with the control box 5, and the air pressure clamping device 3 is equipped with a pressure sensor 4 and a solenoid valve group 6, and the pressure sensor 4 and the solenoid valve group 6 are respectively connected to the control box 5. As a preference, the bottom plate 1 is in the shape of a rectangle, and four corners of the bottom surface are respectively equipped with rollers, and the clamping operation is realized by electric control and pneumatics led by the control box 5 . As a preference, a PLC hardware control system is installed in the control box 5, and a bus interface is provided on the control box. An interface module and an execution module are also installed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com