Construction method for large ultra-deep well

A construction method and ultra-deep technology, applied in caissons, infrastructure engineering, construction, etc., can solve the problems of construction personnel and machinery safety threats, high construction risks, and difficulty in sinking in place, so as to save engineering construction costs and avoid piping surges And quicksand, shorten the effect of the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The construction method of the large ultra-deep caisson of the present invention comprises the following construction steps:

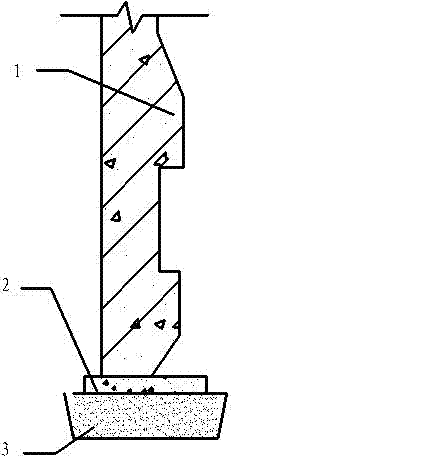

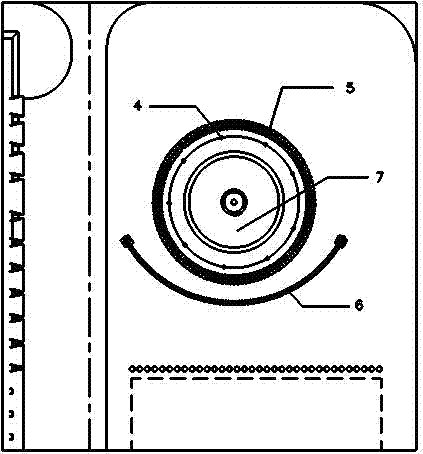

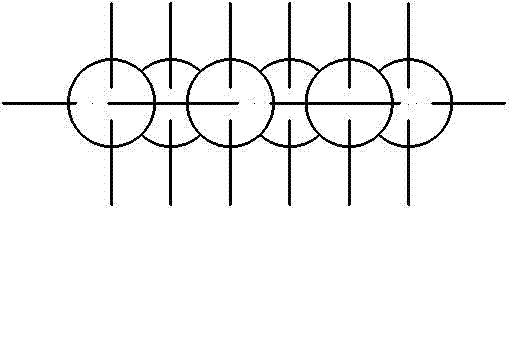

[0042] a. Water-stop curtain construction of rotary grouting piles

[0043] see now Figure 1 to Figure 4 , figure 1 It is a schematic diagram of the cushion structure of the embodiment of the present invention, figure 2 It is a schematic diagram of the arrangement of jet grouting piles and deep well points in the embodiment of the present invention, Figure 3a It is a schematic diagram of the socket connection of single-row jet grouting piles according to the embodiment of the present invention, Figure 3b It is a schematic diagram of socketing of double-row jet grouting piles according to an embodiment of the present invention, Figure 4 It is a schematic cross-sectional view of jet grouting pile, deep well and caisson according to the embodiment of the present invention. During the construction of the water-stop curtain of the rotary gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com