Power and signal transmission drill stem

A signal transmission and drill pipe technology, which is applied in the direction of drill pipe, drill pipe, drilling equipment, etc., can solve the problems of joints occupying a large inner diameter space, poor reliability of electrical plugs, and failure to meet requirements, etc., to increase transmission efficiency and simple structure , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

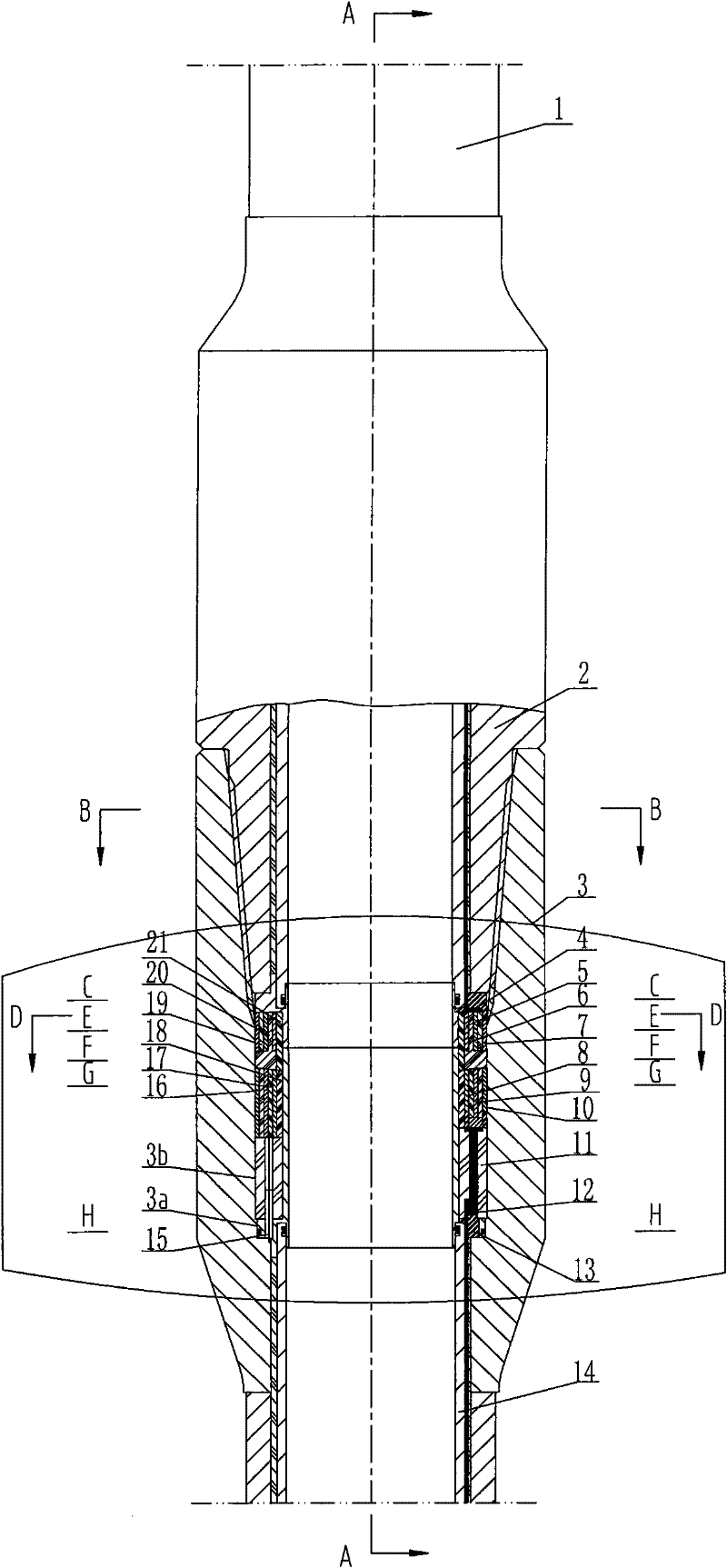

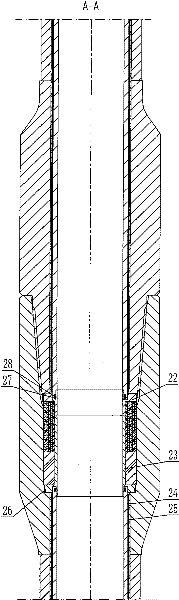

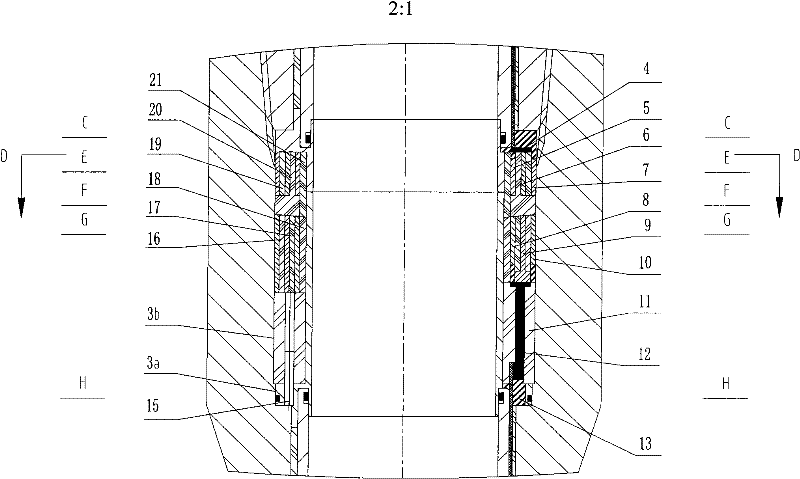

[0020] exist figure 1 and figure 2 The medium power and signal transmission drill pipe is composed of three parts: special drill pipe joint, electrical joint and power and signal transmission drill pipe body. Among them, the special drill pipe joint includes two parts: the special drill pipe male joint 2 and the special drill pipe female joint 3. The male electrical joint is installed at the special drill pipe male joint 2, and the female electrical joint is installed at the special drill pipe female joint 3. The special drill pipe male joint 2 and the special drill pipe female joint 3 are connected to the drill pipe body for power and signal transmission; the special drill pipe male joint 2 and the special drill pipe female joint 3 are threadedly connected during the working process of the power and signal transmission drill pipe, The male electrical connector and the female electrical connector are in close contact to transmit current and signal, and at the same time, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Large diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com