Circulating water recycling and cooling system for thermal power plant

A cooling system and circulating water technology, applied in applications, steam engine installations, fish farming, etc., can solve the problems of lack of waste heat recycling system, high cost of power generation, energy waste, etc., and achieve low temperature, simple structure and reliable operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

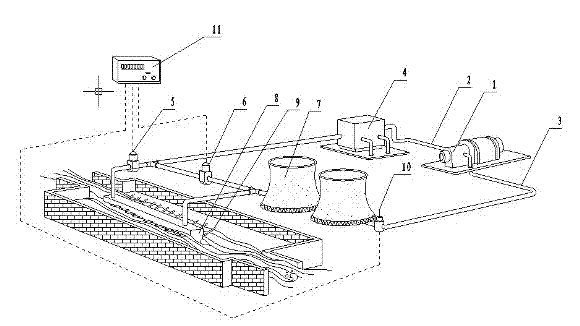

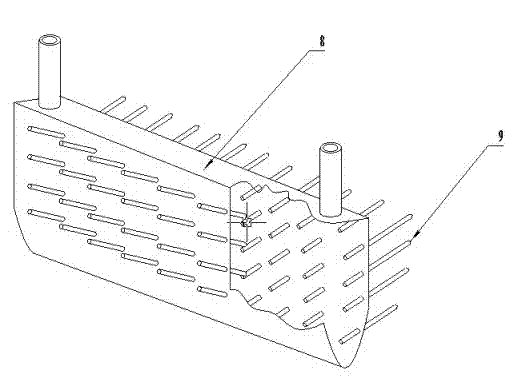

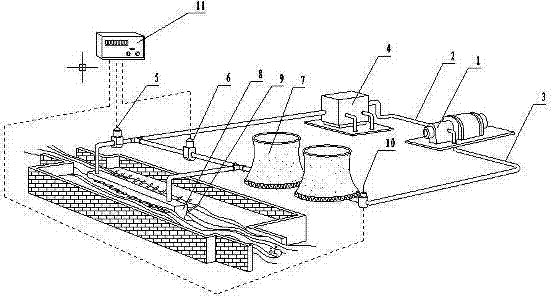

[0012] Example: a structure such as figure 1 , figure 2 As shown, the inner cooling circuit 1 of the generator, the cooling water output pipe 2, the return pipe 3, the user heat exchanger 4, the solenoid valve A5, the solenoid valve B6, the water drying tower 7, the culture pond heat exchanger 8, and the superconducting heat pipe 9 , a temperature sensor 10 and a temperature control switch 11, wherein one end of the cooling water output pipe 2 is connected to the inner cooling circuit 1 of the generator, and the other end is respectively connected to the user heat exchanger 4, the solenoid valve A5, the culture pond heat exchanger 8, Water drying tower 7, temperature sensor 10 are connected with return pipe 3, superconducting heat pipe 9 forms a whole with culture pond heat exchanger 8, and temperature control switch 11 is connected with temperature sensor 10, electromagnetic valve A5 and electromagnetic valve B6 respectively by electric line. The user heat exchanger is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com