Parallel compact-type electro-hydraulic push rod

An electro-hydraulic push rod, compact technology, applied in the direction of fluid pressure actuators, etc., can solve the problem of bulky, etc., to achieve the effect of reduced volume, small friction, and good friction resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

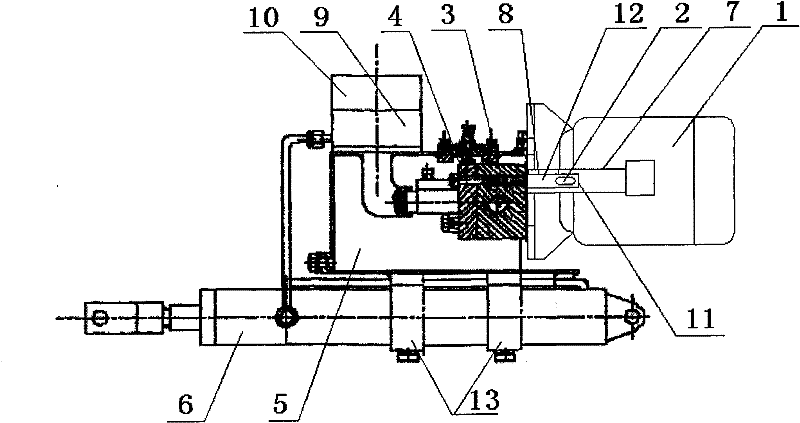

[0014] see figure 1 As shown, a side-by-side compact electro-hydraulic push rod includes a motor 1, an oil pump 3, a hydraulic manifold 4, an oil tank 5 and an oil cylinder 6, the motor 1 is provided with a motor shaft 7, and the oil pump is a two-way gear pump And be provided with oil pump shaft 8, described oil cylinder 6 is detachably installed on the bottom of fuel tank 5 by bracket 13, and is not on the same main axis with motor, and this bracket 13 is connected on the fuel tank 5 by flange. The hydraulic manifold 4 is connected to the reversing valve 9 installed on the oil tank through the pipeline, the reversing valve 9 is connected to the manual pump 10, and the reversing valve 9 is connected to both ends of the oil cylinder 6 through the pipeline, and the manual pump 10 is a radial multi-piston plunger pump. The pump body of the manual pump 10 is made of modified ultra-high molecular weight polyethylene material. A displacement sensor is installed inside the oil cylin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap