Online calibration method of indicator diagram test equipment and connection structure thereof

A technology for testing equipment and connection structures, applied in the direction of calibration/testing of force/torque/power measuring instruments, measuring devices, instruments, etc. Small impact, reduced downtime, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

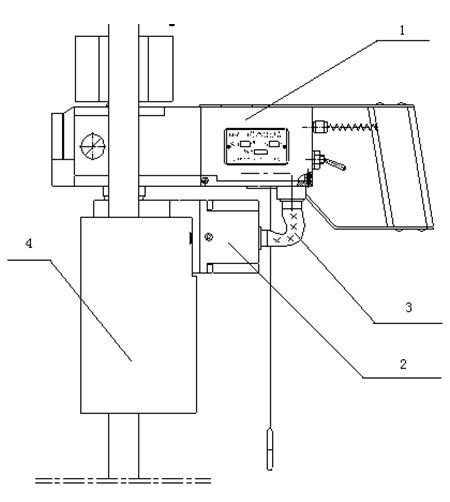

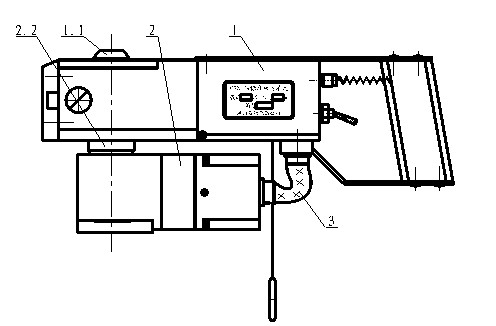

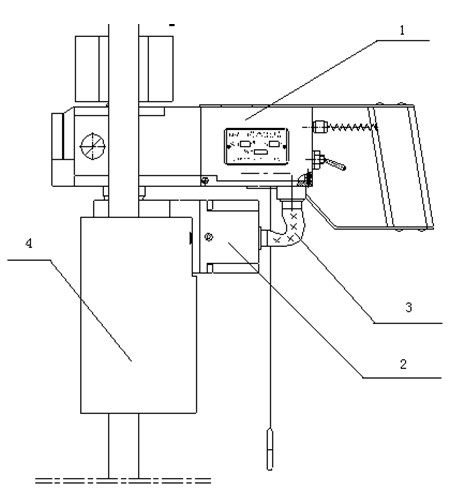

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but not as any limitation to the present invention.

[0014] Embodiments of the present invention: used standard diagram test equipment 1 in the present invention is the finished product of the diagram test equipment sold on the market, when choosing this as the equipment that standard diagram test equipment is used, choose as standard diagram The nominal test accuracy of test equipment 1 should be higher than the nominal test accuracy of online dynamometer test equipment 2; usually, the error of the nominal test accuracy of standard dynamometer test equipment 1 should be less than or equal to 0.2% FS (FS is full scale accuracy). The online dynamometer testing equipment 2 in the present invention is the dynamometer testing equipment installed on the field pumping unit.

[0015] An online calibration method of a kind of power diagram testi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com