Stiffness testing device for gas bearing

A technology of air bearing and testing device, which is applied in the direction of mechanical bearing testing, etc., can solve the problems of insufficient flexibility and difficulty of the performance testing bench, and achieve the effect of reliable testing results and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

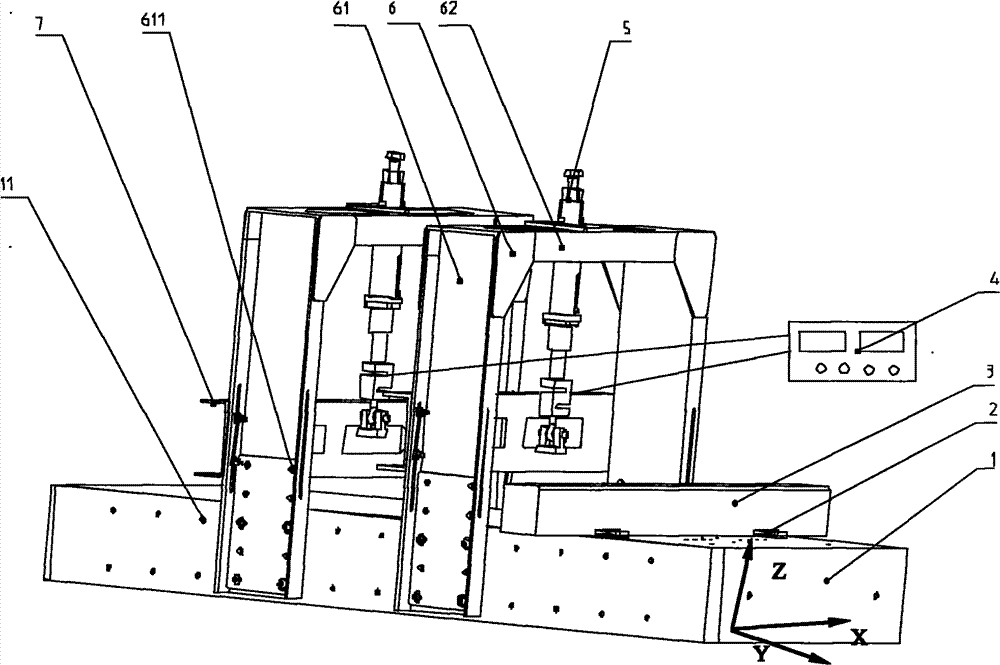

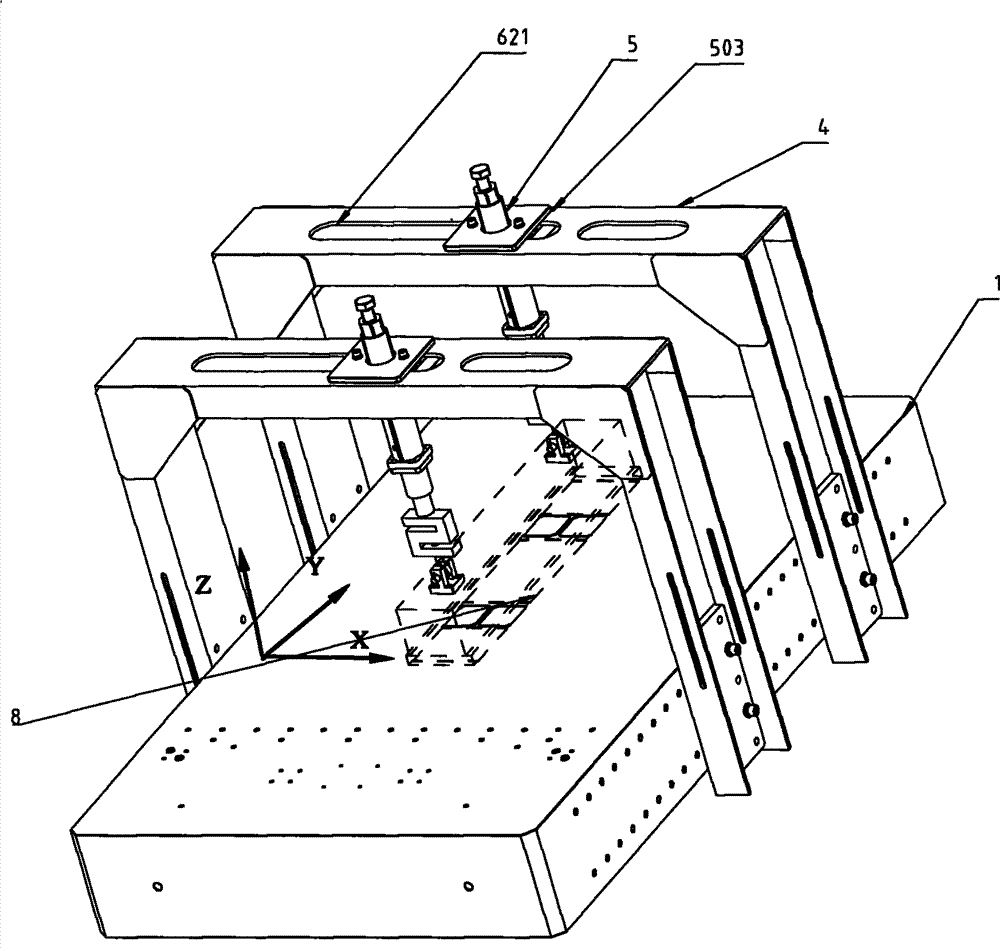

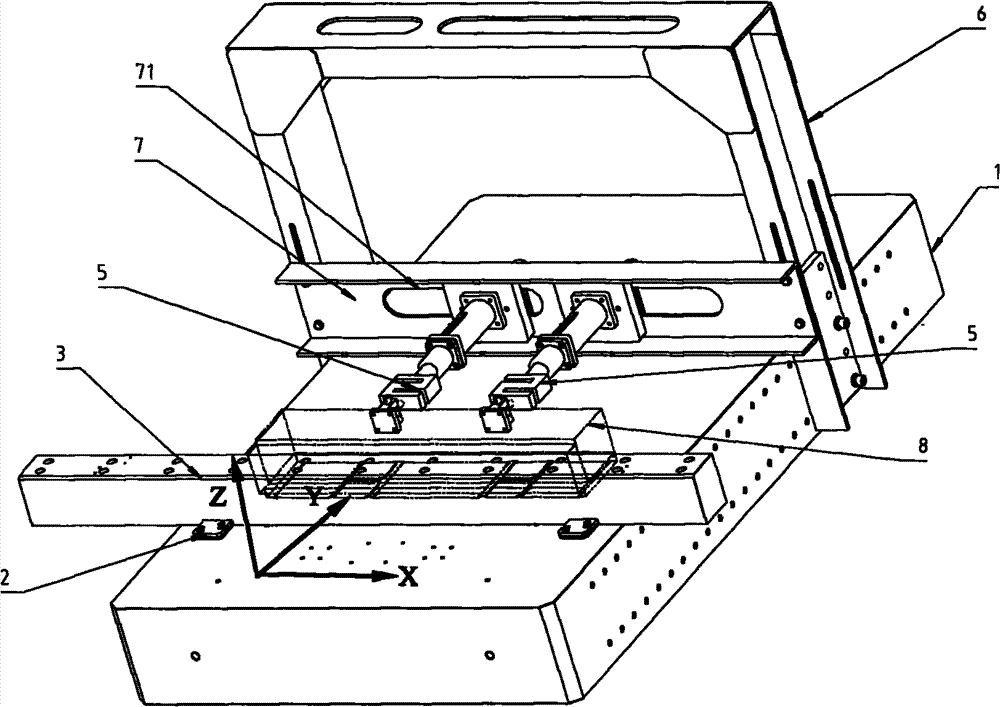

[0030] The following will combine Figure 1 ~ Figure 4 The stiffness testing device of the air bearing of the present invention is further described in detail.

[0031] see Figure 1 ~ Figure 3 The stiffness testing device of the air bearing of the present invention comprises a platform 1, a guide rail positioning block 2, a guide rail 3, a display instrument 4, at least a loading mechanism 5, at least a gantry 6 and an inductance micrometer (in the figure not shown);

[0032] The guide rail 3 is arranged on the upper surface of the platform 1 through the guide rail positioning block 2;

[0033] The gantry 6 is installed on the platform 1;

[0034] The loading mechanism 5 is installed on the gantry 6 in a direction perpendicular to the horizontal plane or in a direction parallel to the horizontal plane;

[0035] The display instrument 4 is connected with the loading mechanism 5;

[0036] The component under test 8 is arranged on the upper surface of the platform 1, the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com