Laser coherence detection device for ceramic product surface defect

A coherent detection and product technology, which is applied in the measurement of phase influence characteristics, optical testing flaws/defects, etc., can solve the problems of poor adaptability and low resolution, and achieves small volume and energy consumption, simple system structure, and improved detection resolution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

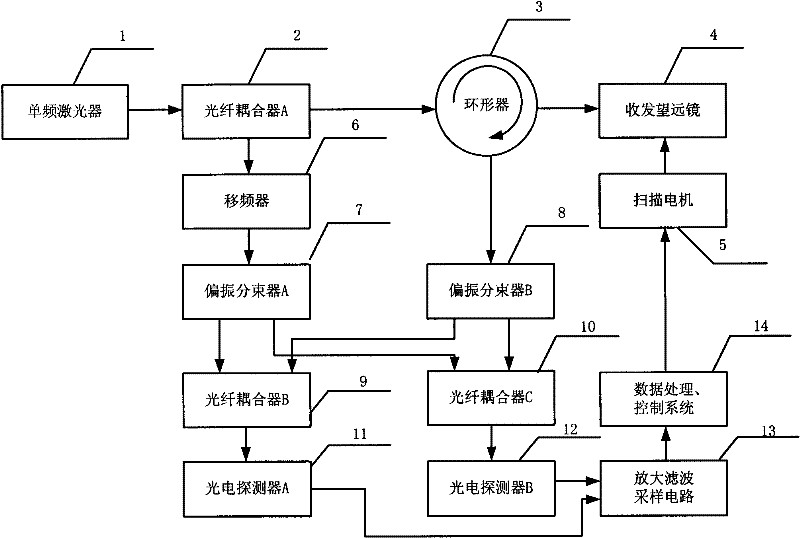

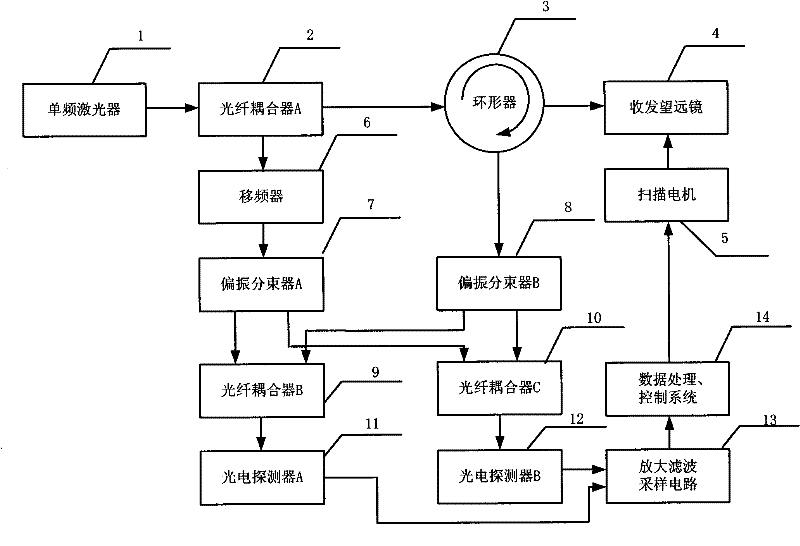

[0010] exist figure 1 Among them, the single-frequency laser 1 is connected to the fiber coupler A2, the fiber coupler A2 is connected to the circulator 3, one end of the circulator 3 is connected to the transceiver telescope 4, and the other end is connected to the polarization beam splitter B8. The fiber coupler A2 is connected to the frequency shifter 6, and the frequency shifter 6 is connected to the polarization beam splitter A7. The scanning motor 5 is connected with the transceiver telescope 4 , and the data processing control system 14 is connected with the scanning motor 5 . The polarization beam splitter A7 is connected to the fiber coupler B9 and the fiber coupler C10 respectively, and the polarization beam splitter B8 is connected to the fiber coupler B9 and the fiber coupler C10 respectively. The fiber coupler B9 is connected to the photodetector A11, and the fiber coupler C10 is connected to the photodetector B12. The photodetector A11 and the photodetector B12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com