Vertical test equipment for electronic assemblies

A technology for testing equipment and electronic components, applied in static memory, instruments, etc., can solve the problems of increasing test costs, large space, and unfavorable miniaturization of test sites, and achieve the effect of reducing test costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

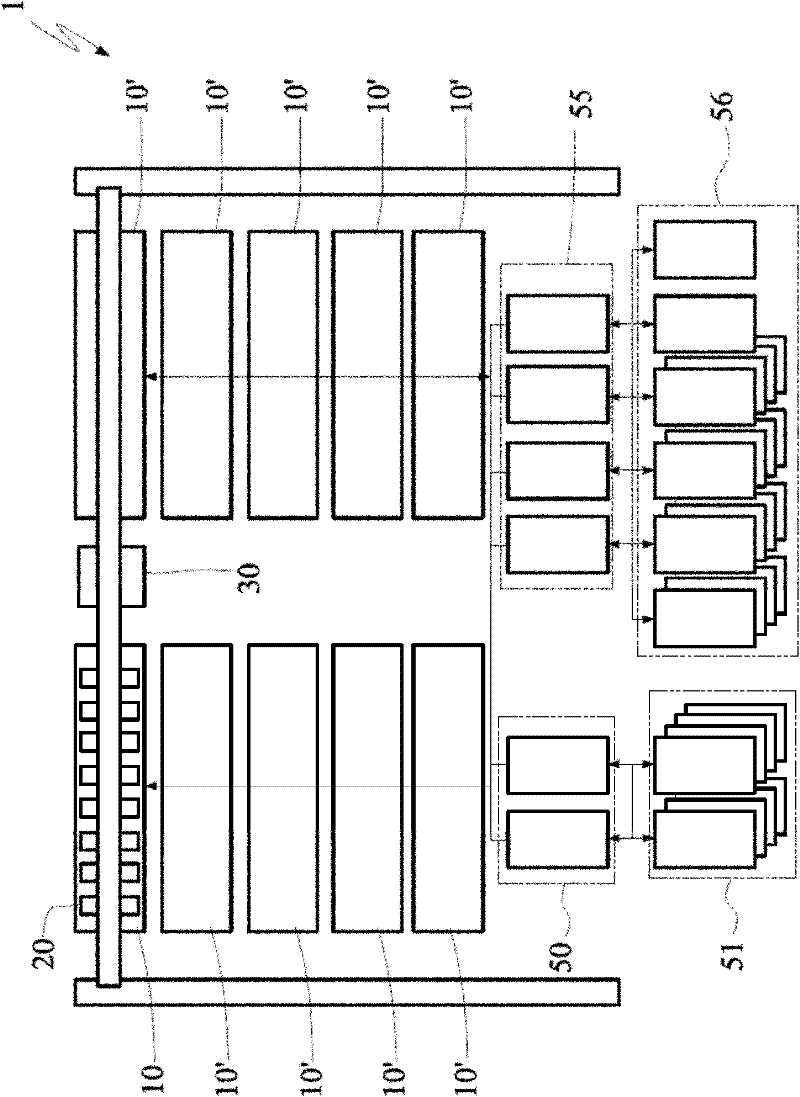

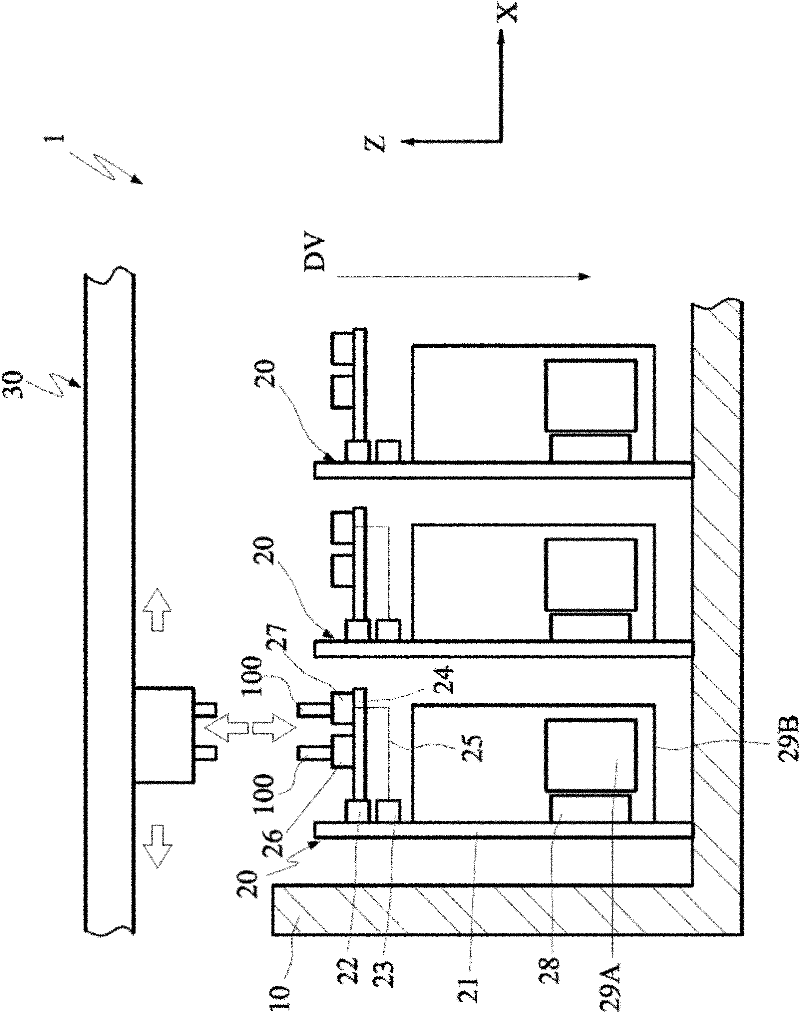

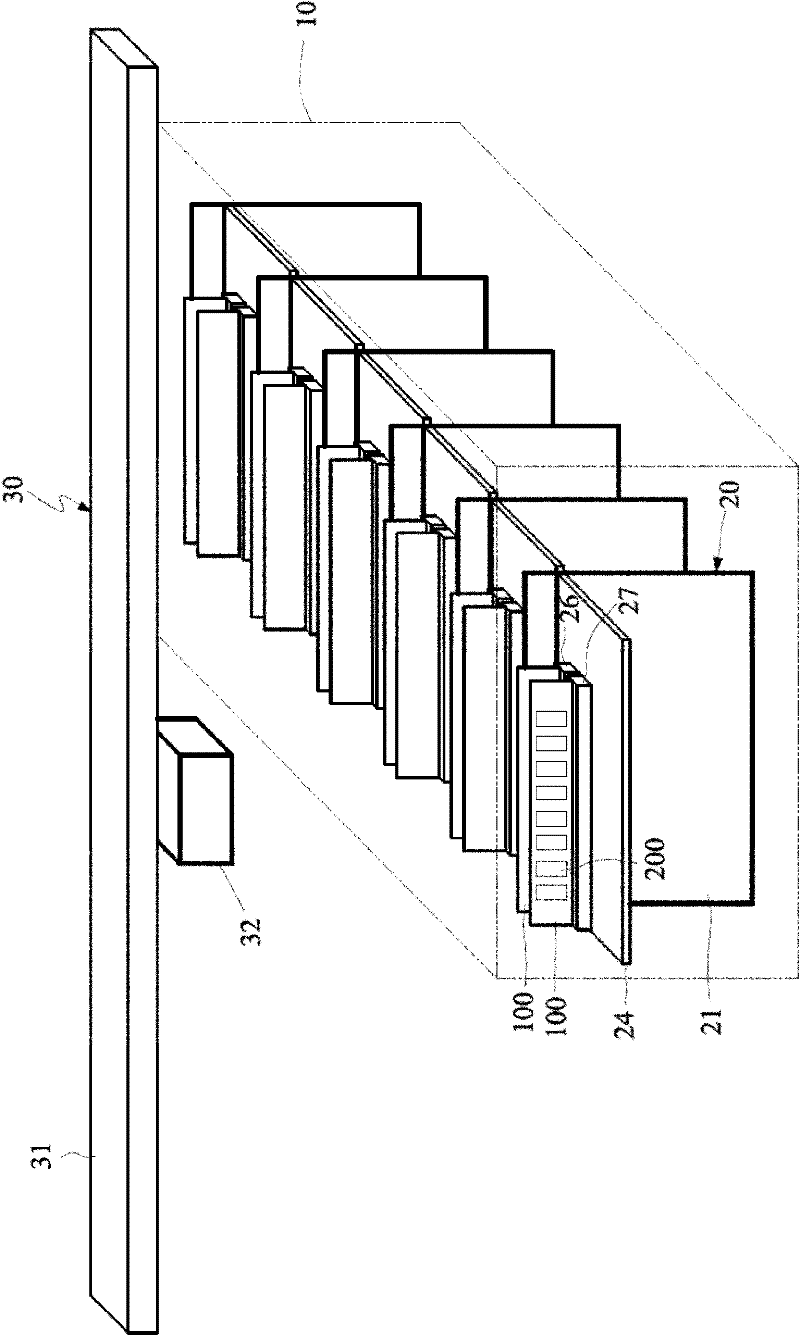

[0052] figure 1 An overall schematic view of the upright testing device according to the first embodiment of the present invention is shown. figure 2 show figure 1 A partial schematic of the upright test setup. image 3 A partial perspective schematic of the upright test apparatus is shown.

[0053] Such as Figures 1 to 3 As shown, the vertical testing device 1 for electronic components of this embodiment includes a box component 10 , a plurality of first motherboard components 20 and a handler 30 . Of course, the upright testing device 1 for electronic components may further include a plurality of additional box components 10 ′. Additional box assembly 10' functions similarly to box assembly 10 to increase test throughput. In the following, only the internal structure of a single box assembly 10 will be used for illustration.

[0054] The first motherboard assembly 20 is disposed in the case assembly 10 . Each first motherboard assembly 20 includes a motherboard 21 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com