Buck converter for railway LED (Light Emitting Diode) signal lamp

A technology of converters and signal lamps, which is applied in the direction of electric lamp circuit layout, lighting devices, light sources, etc., and can solve the problems of many components, signal lamps no longer emitting light, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

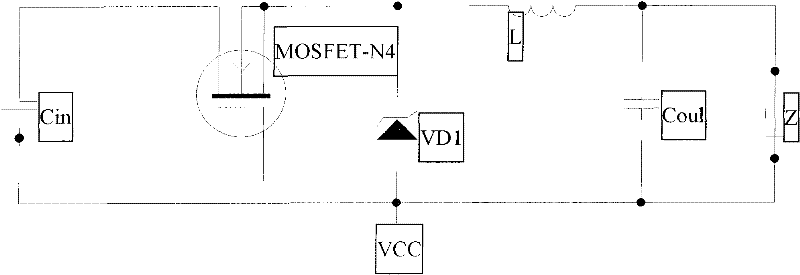

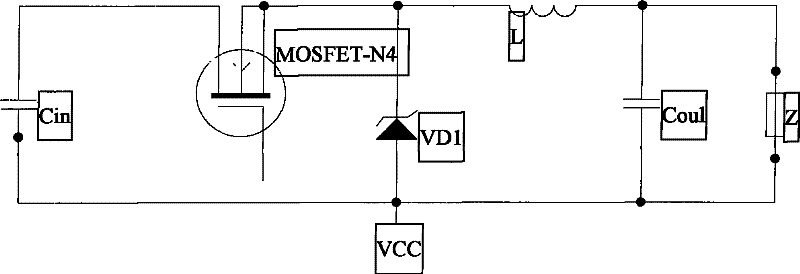

[0011] The present invention adopts the solution of buck converter technology and NPN transistor constant current to drive a single LED junction, 10 LEDs with a rated current of 250mA are connected in parallel, and a single power LED adopts a constant current drive circuit.

[0012] The constant voltage Buck converter adopts an integrated Buck controller LM2679 with an output peak current up to 8.1A and an adjustable output voltage. The integrated Buck controller LM2679 includes a peak current overload protection adjustment resistor, a soft-start capacitor, an output capacitor, and a freewheeling converter. Diode input capacitor, filter inductor, output voltage feedback network.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com