One-step form grinding method for double races

A technology of forming grinding and double raceway, which is applied to the parts of grinding machine tools, grinding/polishing equipment, grinding machines, etc., can solve the problems affecting the bearing life and bearing capacity, and the accuracy is difficult to meet the requirements, so as to improve the production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

[0016] The one-time forming grinding method of double raceway of the present invention comprises the following steps:

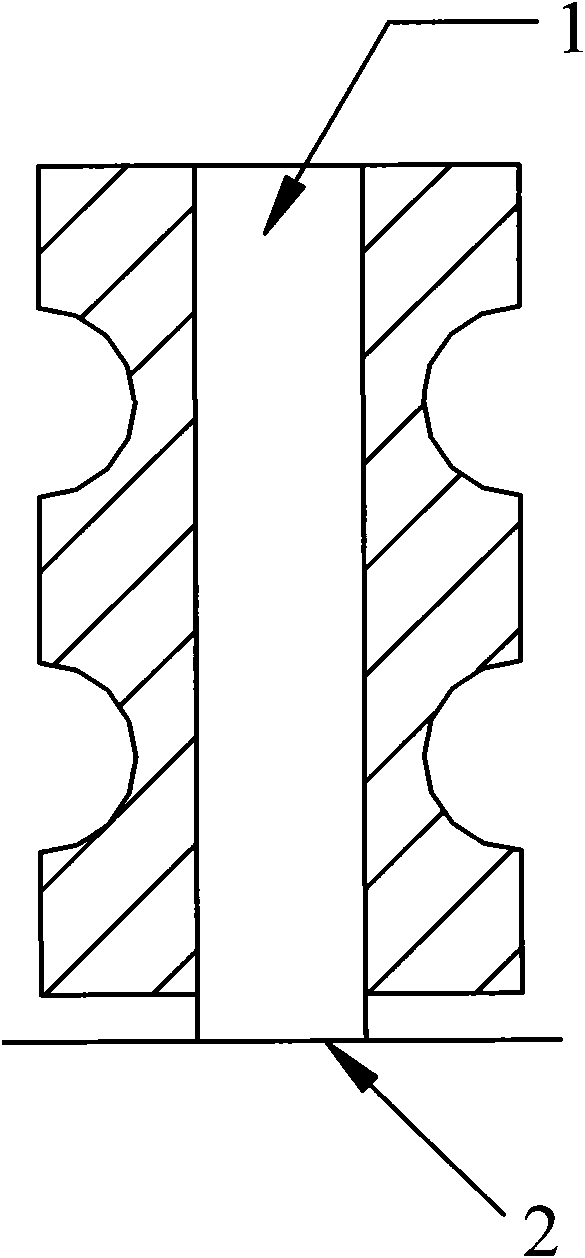

[0017] Step 1: If figure 1 As shown, the diamond roller 1 is installed on a bracket 2, and the bracket 2 is fixed on the machine tool platform. The diamond roller is made of diamond bonded and has the ability to grind the grinding wheel. The centerline of the diamond roller should be parallel to the centerline of the spindle of the grinding wheel. The bracket should have a certain rigidity and be able to keep parallel with the main shaft of the grinding wheel, so as to avoid errors during correction. The diamond roller 1 and the bracket 2 constitute a grinding wheel corrector, and the grinding wheel corrector should have a rotation function and can rotate positively and negatively accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com