High-temperature-resistant heat-proof paint and preparation and use methods thereof

A heat-resistant coating and high-temperature-resistant technology, applied in the field of coatings, can solve the problems of insufficient thermal protection of aerospace carriers, and achieve the effect of solving thermal protection problems and keeping the paint film intact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

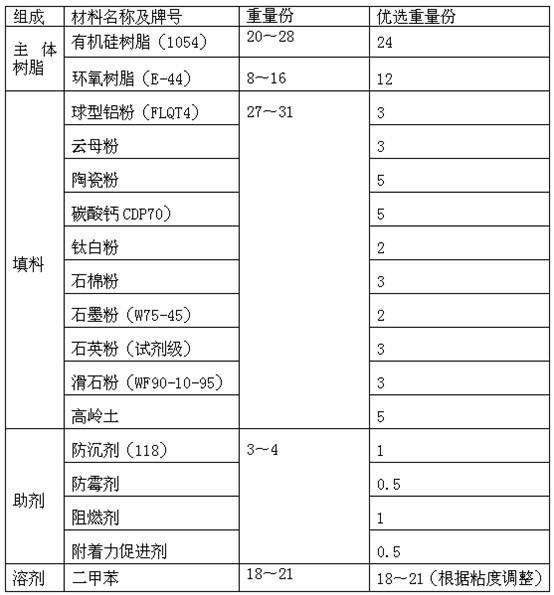

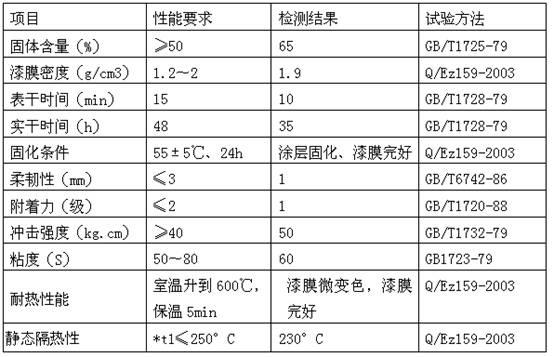

[0015] Embodiment 1: coating formulation is shown in Table 1

[0016] Table 1 Formula of high temperature heat insulation coating

[0017]

[0018] Preparation:

[0019] (1) Weighing: First weigh the main resin and various additives and add them to the tank, then weigh the heat-resistant filler to add, finally weigh xylene, and add 60% of xylene to the tank, the rest Xylene was added during grinding.

[0020] (2) Premixing: Stir and mix the weighed material evenly with a nylon stick.

[0021] (3) Dispersion: Disperse the premixed raw materials at a speed of 480r / min~520r / min for 30min~40min, and then disperse at a speed of 680r / min~720r / min for 100min~120min at a high speed. Ensure that the coating system is premixed evenly.

[0022] (4) Grinding: put the pre-mixed uniform raw materials into the horizontal sand mill, add the remaining xylene, install the grinding medium (glass beads or zirconia beads of φ1.5~φ3), connect the cooling water, set After the temperature and...

Embodiment 2

[0025] Embodiment 2: Spray coating of test piece, mainly including pretreatment of test piece, preparation of coating, spraying and curing.

[0026] (a) Pretreatment of the test piece: the test piece (anodized aluminum test piece, oxidized magnesium test piece) is cleaned with gasoline or acetone.

[0027] (b) Coating preparation: Weigh 500g of the coating prepared in Example 1, and then weigh 15g of the amine curing agent diethylenetriamine, mix evenly, and add solvent (diethylenetriamine) to adjust the viscosity to be easy to spray.

[0028] (c) Spraying: Choose a small spray gun for spraying, the air pressure is controlled at about 0.3MPa, the distance of the spray gun is about 20cm, and the thickness of the single-layer wet film is between 20μm and 30μm. The thickness of the conventional performance and heat resistance coating is controlled at 30 μm to 50 μm, and the thickness of the heat insulation coating is controlled at 0.7mm to 0.8mm.

[0029] (d) Curing: The test pi...

Embodiment 3

[0034] Embodiment 3: The spraying of the main wing mainly includes the pretreatment of the test piece, the process protection painting of the test piece, the total spraying of heat-resistant paint, and curing.

[0035] (a) Pretreatment of the main wing: the outer surface of the main wing (magnesium alloy oxidation) is cleaned with gasoline or acetone.

[0036] (b) Process protection spraying: the main wing needs to be sprayed within 24 hours after oxidation as a process protection, and the main wing is sprayed with the paint of Example 1 as a process protection.

[0037] (c) Total spraying of high-temperature heat-resistant and heat-resistant paint: weigh 100 parts of the paint in Example 1 in proportion, 3 parts of amine curing agent diethylenetriamine, mix evenly, and adjust the solubilizer (diethylenetriamine) to achieve an easy-to-spray coating viscosity.

[0038] Choose a large spray gun for spraying, the air pressure is controlled at about 0.35MPa, the spray gun dista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com