Method of manufacturing gan-based film

A base film and axial direction technology, which is applied in chemical instruments and methods, semiconductor/solid-state device manufacturing, crystal growth, etc., can solve the problems of difficult to obtain GaN substrates and expensive GaN substrates, and achieve less warpage, large master The effect of surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

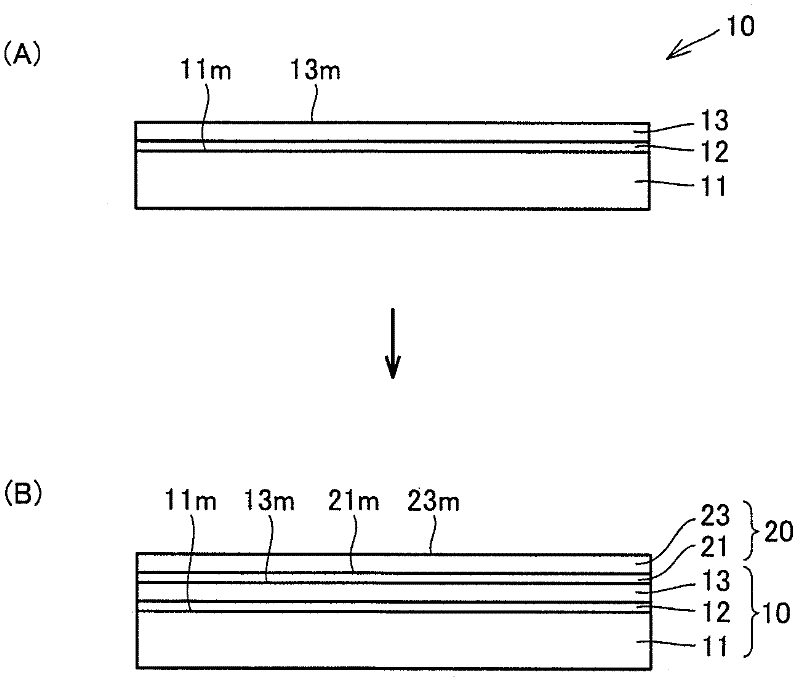

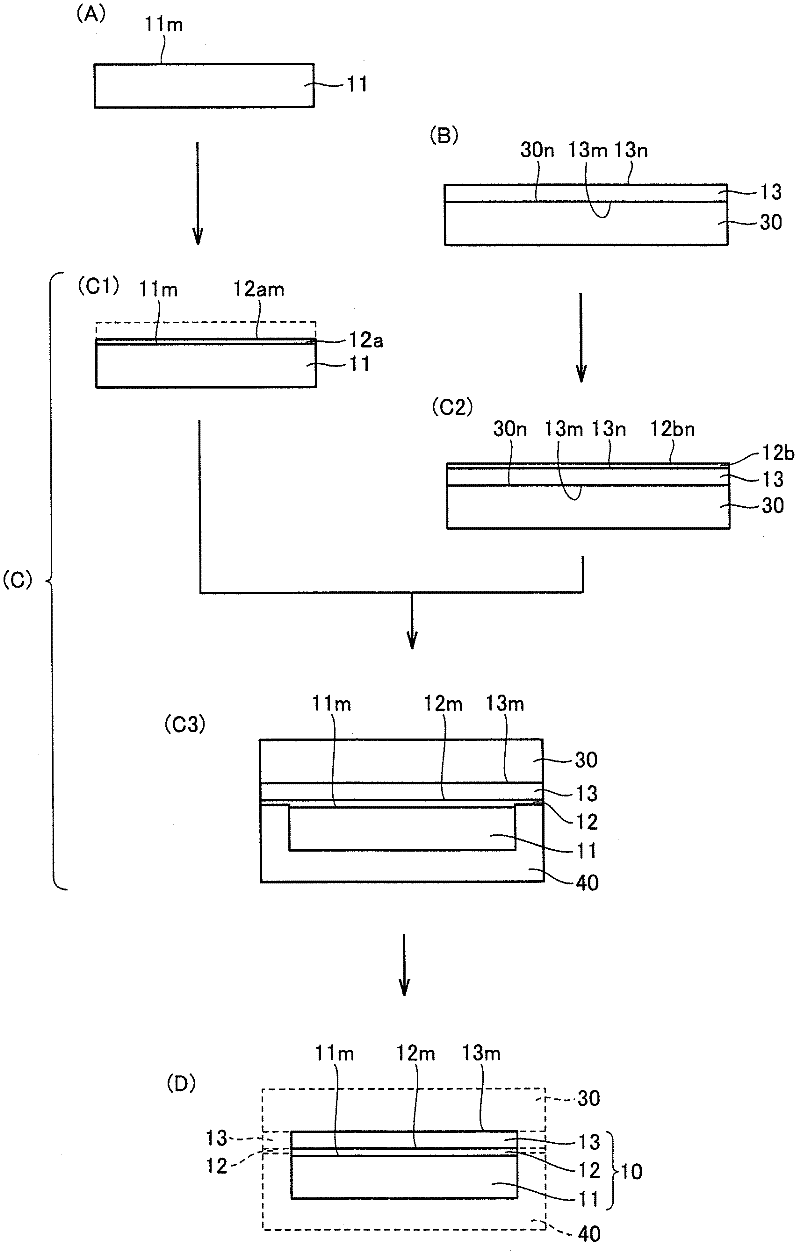

Method used

Image

Examples

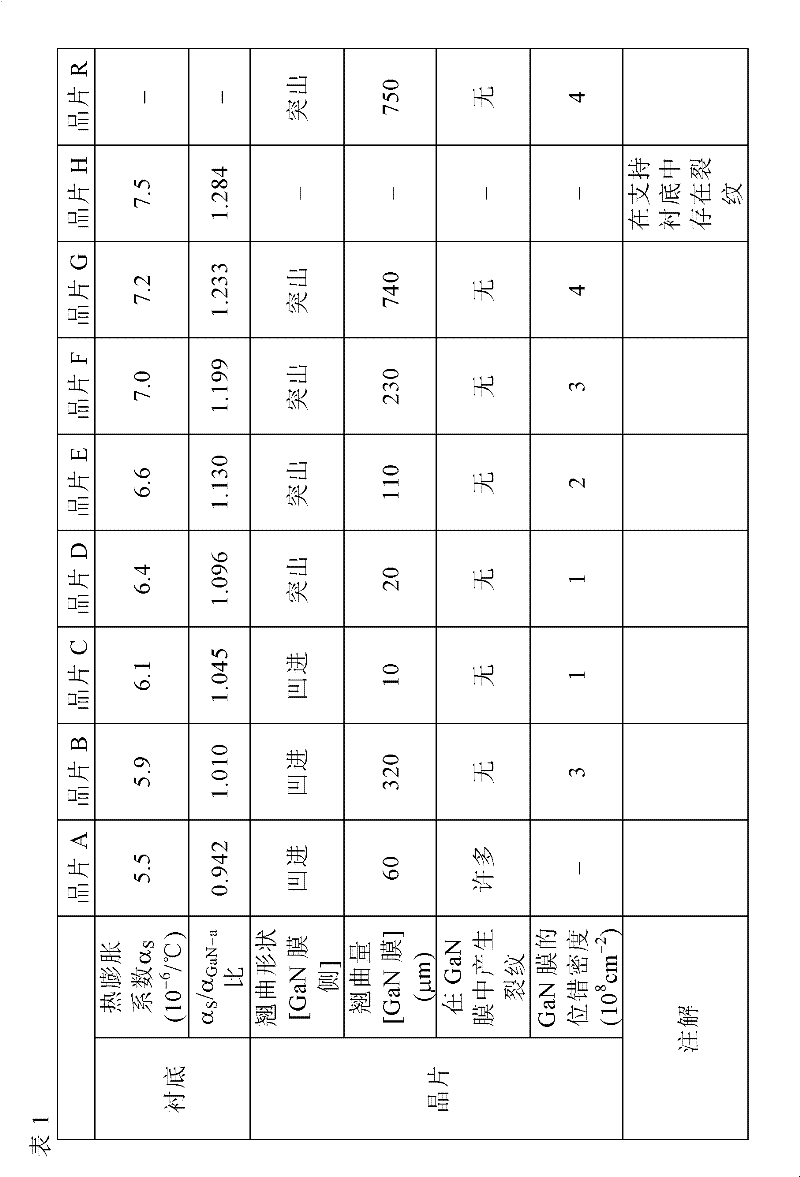

Embodiment 1

[0038] 1. Measurement of thermal expansion coefficient of GaN crystal

[0039] grown from the HVPE method and have a 1 x 10 6 cm -2 dislocation density, 1×10 18 cm -2 Si concentration, 1×10 17 cm -2 The oxygen concentration and 1 x 10 16 cm -2 A GaN single crystal cut with a carbon concentration of 2 x 2 x 20 mm for evaluation (having an a-axis in the longitudinal direction and having any one of a C plane and an M plane as a plane parallel to the longitudinal direction, And the accuracy of plane orientation is within ±0.1°).

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com