Template with door frame for concrete pouring wall

A concrete and door frame technology, which is applied to formwork/formwork/work frame, connection parts of formwork/formwork/work frame, on-site preparation of building components, etc., can solve the problem of slow assembly speed, complex formwork structure and slow efficiency and other problems, to achieve the effect of simple structure, low cost and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

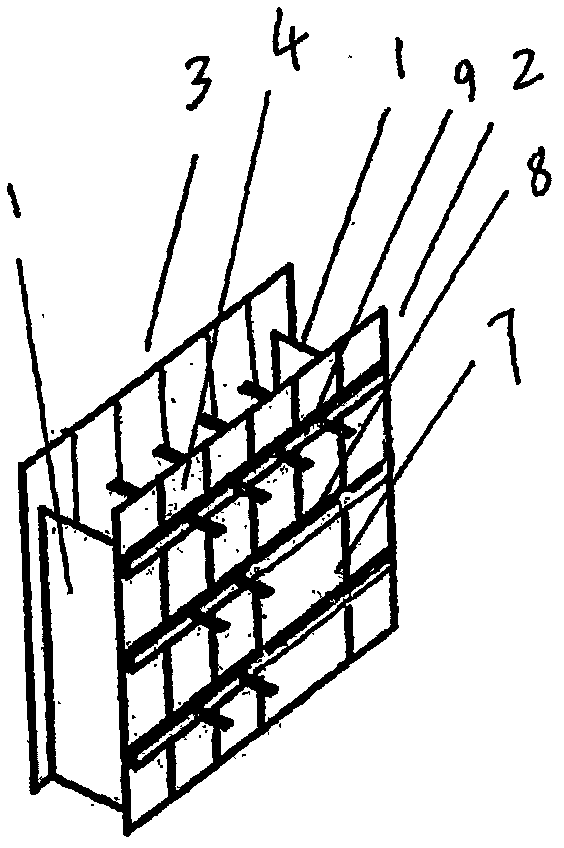

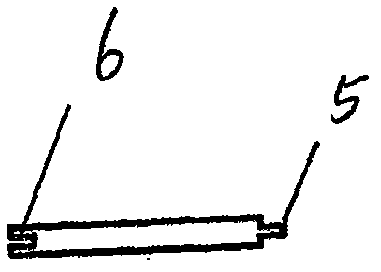

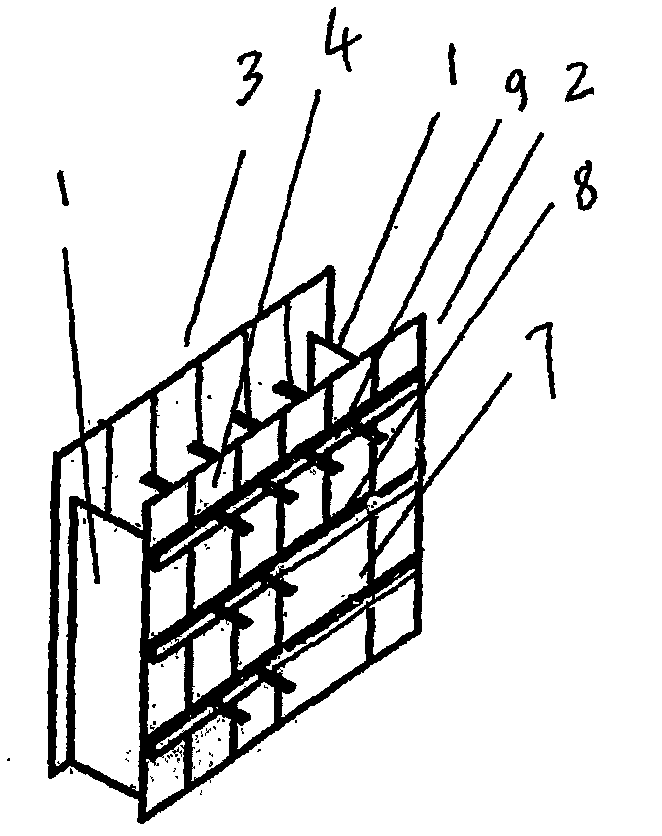

[0012] control figure 1 , figure 2 It can be seen that, including the left and right end face plates 1, a front panel 2 and a rear panel 3 are respectively arranged on the front and rear sides of the left and right end face plates 1, and the front panel 2 and the rear panel 3 are composed of several pieces. The panel unit 4 is composed of one side of the panel unit 4 with a convex edge 5, and the other side is a card slot 6 used in conjunction with the convex edge 5. The structure of this panel unit is conducive to the rapid assembly and combination of the panel unit. The panel units 4 at both ends of the right are fixedly connected to the left and right end face plates respectively by screws (not marked in the figure), and there is a reserved space 7 for the door frame at the position corresponding to the front panel and the rear panel on the lower right side. A support plate 8 is provided above the reserved space 7 of the door frame, and a reinforcing rod 9 is respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com