Compression device and operation control method thereof

A compression device and operation control technology, which is applied in the direction of pump control, liquid variable displacement machinery, machine/engine, etc., can solve the problem of frequent switching of compressor start and stop, frequent switching of loading and unloading, prone to abnormalities or failures, shortened Unit time and other issues to achieve the effect of saving power consumption, saving power consumption, and reducing the frequency of changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0048] based on Figure 6 ~ Figure 10 The first embodiment of the method and device of the present invention will be described. exist Image 6 Among them, the compression device 10 includes four air compressors 12a to 12d. The electromagnetic switch 16a-d which switches and controls each motor 14a-d of the air compressors 12a-d is provided as an unloading mechanism which makes the air compressors 12a-d into an unloaded state. However, the unloading mechanism is not limited to this.

[0049] In addition, examples of the unloading mechanism include (1) a mechanism using an intake valve, (2) a mechanism using a vent valve, and the like. Specifically, (1) the mechanism using the suction valve is to continue driving the compressor as it is, and to make the suction valve variable to reduce the suction volume of the compressor to perform no-load operation. This method is mainly applicable to screw compressors. In addition, another mechanism using the suction valve is to continue...

Embodiment approach 2

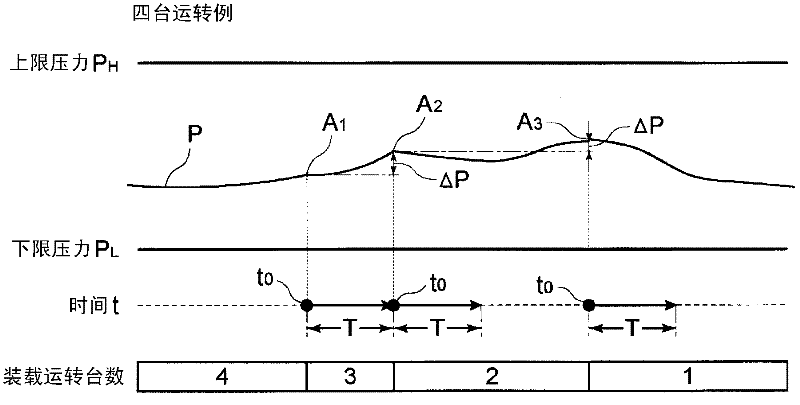

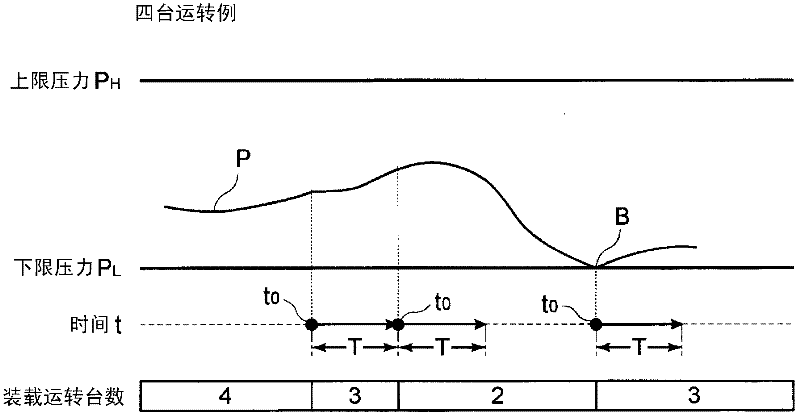

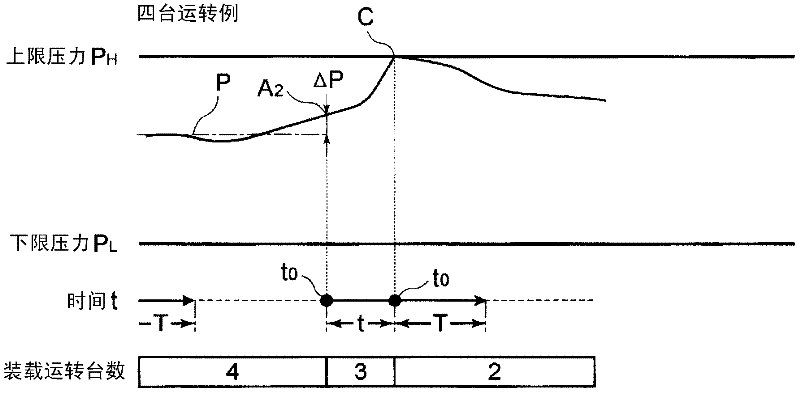

[0075] Next, as a second embodiment, according to Figure 11 Another pressure control example of the operation control of the compression device 10 will be described. Figure 11 It is an example of pressure control from the middle of operation. In the figure, when the ejected air pressure P drops to the lower limit pressure P every time in the low-pressure area L , load switching control is performed. In the medium pressure domain, after the number of operating compressors is changed, the starting point t 0 After the control time T, when the distance from the starting point t 0 The pressure change ΔP is the set increase ΔP S In the above case, unload switching control is performed.

[0076] During unloading promote pressure P P and upper limit pressure P H In the high-pressure domain between, the starting point t after the change of the operating number of the compressor is taken as the starting point t 0 After the control time T, when the ejection pressure P is the un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com