Variable-frequency energy-saving control system of tunnel kiln

An energy-saving control system and tunnel kiln technology, which is applied to the types of furnaces, furnaces, lighting and heating equipment, etc., can solve the problems of high consumption of machines in the tunnel kiln and unstable temperature control, so as to reduce unnecessary waste of energy, reduce noise and Mechanical wear, reduce the effect of blind operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

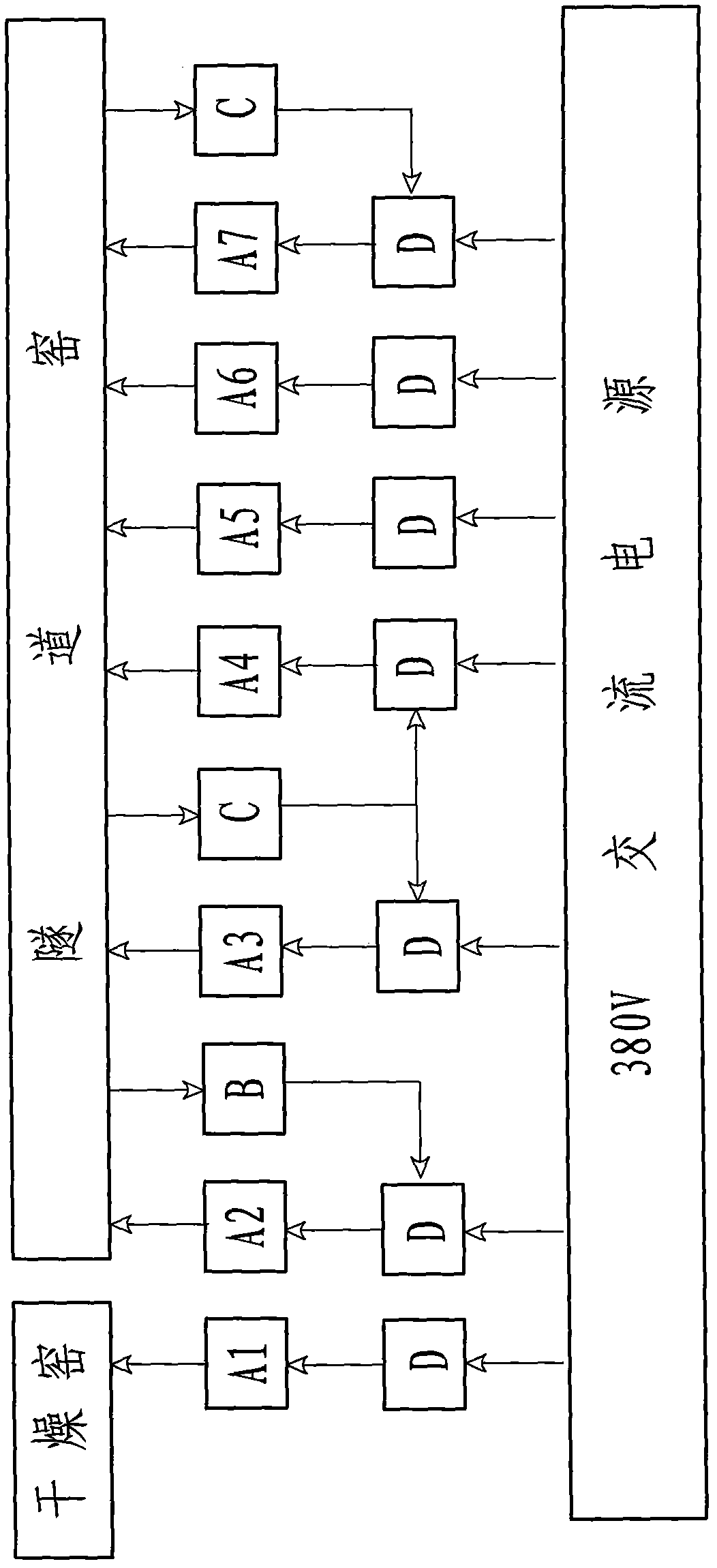

[0009] figure 1 As shown, the tunnel kiln frequency conversion energy-saving control system of the present invention controls the operation of the fan by connecting a frequency converter between the fan and the power supply installed in the tunnel kiln for sintering refractory bricks, so as to achieve energy-saving and power-saving effects. figure 1 A frequency conversion controller D is installed between the drying exhaust fan A1 of the drying kiln and the AC power supply. The main smoke exhaust fan A2 connected to the tunnel kiln, the smoke exhaust fan A3 under the kiln, the blower A4 under the kiln, the combustion-supporting fan A5, the waste heat extraction fan A6, the cooling fan A7 and the power supply are all equipped with a frequency conversion controller D. A pressure sensor B and a temperature control sensor C are installed inside, the pressure sensor B is connected to the frequency converter connected to the main smoke exhaust fan A1, the frequency converter of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com