Technology for sampling suspension high voltage of depressed collector of traveling wave tube and implementation method of technology

A collector and traveling wave tube technology, applied in the direction of regulating electrical variables, control/regulating systems, instruments, etc., can solve problems such as low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

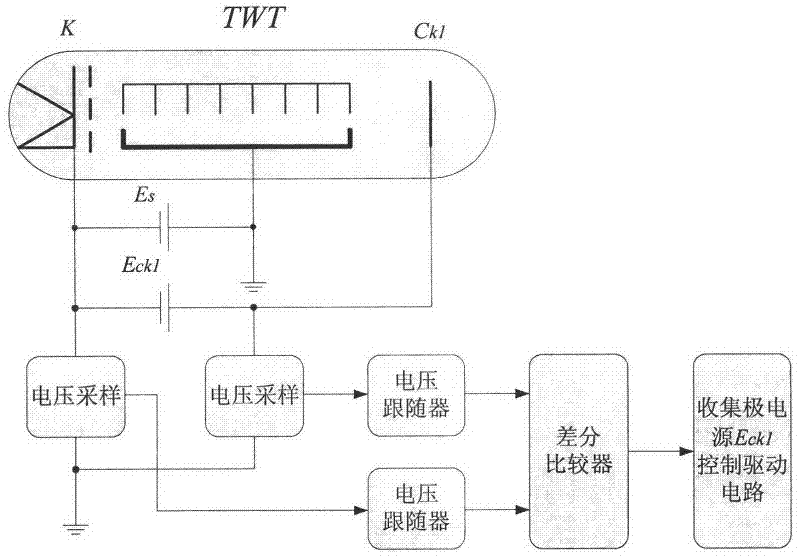

[0008] see figure 1 , Es is the slow-wave line high-voltage power supply, ECk1 is the collector high-voltage power supply, the cathode K of the traveling wave tube is a negative high voltage to the ground, the collector Ck1 is opposite to the cathode plus a positive high voltage ECk1, and ECk1 is suspended to the ground. In order to realize the steady voltage control of ECk1 at the ground potential end, its voltage must be isolated and sampled.

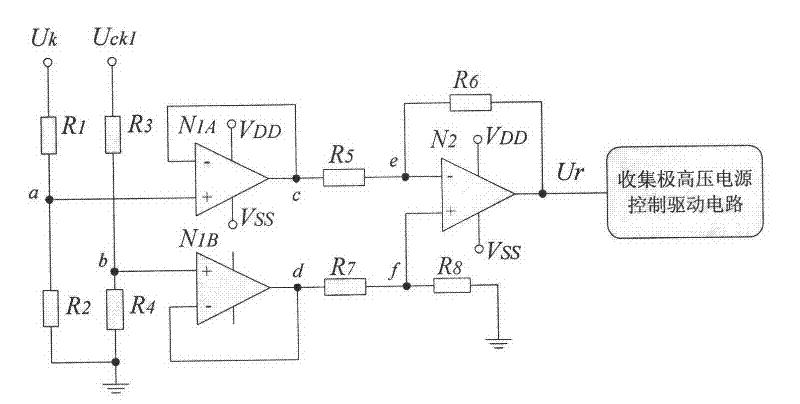

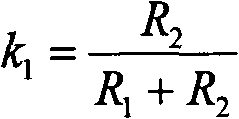

[0009] see figure 2 , Uk and Uck1 are the voltages of the cathode and the collector to the ground respectively, both of which are negative values. R1 and R2 form the cathode negative high-voltage partial pressure sampling circuit, and R3 and R4 form the collector negative high-voltage partial pressure sampling circuit, so their partial pressure ratios are:

[0010] k 1 = R 2 R 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com