Suction cutoff unloader valve for compressor capacity control

A technology of unloader and compressor, which is applied in the direction of pump control, machine/engine, refrigerator, etc., and can solve problems such as impossible distribution of cycle duty ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

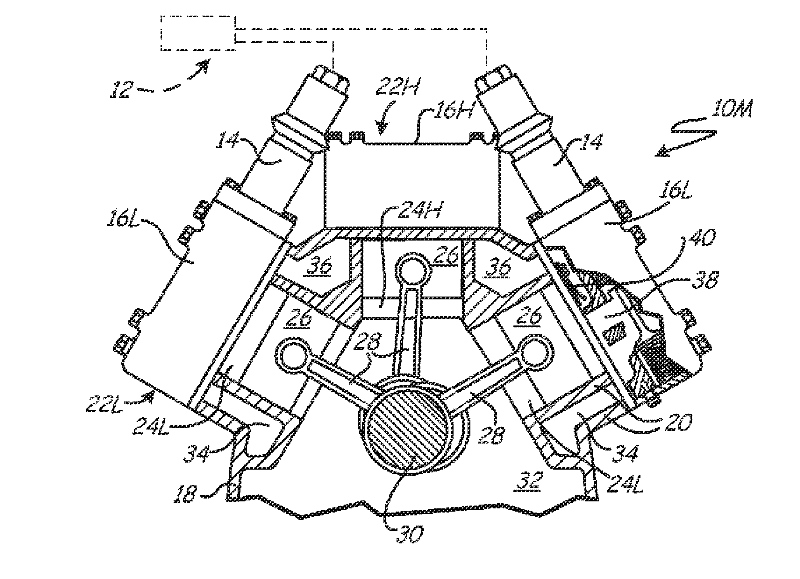

[0012] Figure 1A A cross-sectional view of a multi-stage reciprocating compressor 10M is shown having a controller 12 electrically connected to a suction cutoff unloader valve assembly(s) 14 . In this multi-stage compressor, compression is done in two steps, where the first stage of compression (from suction pressure to intermediate pressure) is performed by the lower stage cylinder(s) and the second stage of compression (from intermediate pressure to discharge pressure) by (one or more) advanced cylinders. In addition to the suction cutoff unloader valve assembly 14, the compressor 10 includes a lower stage cylinder head 16L, a higher stage cylinder head 16H, an outer shell 18, a cylinder block 20, a lower stage cylinder bank 22L, a higher stage cylinder bank 22H, a lower stage cylinder 24L, a higher stage cylinder 24H , Piston 26, connecting rod 28, crankshaft 30, oil tank 32, suction manifold 34 and intermediate manifold 36. Each of the lower and upper cylinder heads 16L ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com