Light-reflecting substrate, substrate which can be mounted in light-emitting element, light-emitting device, and process for production of substrate which can be mounted in light-emitting element

A light-emitting element and manufacturing method technology, applied in the direction of electrical components, semiconductor/solid-state device parts, electric solid-state devices, etc., can solve the problems of reduced reflectivity, silver easy-diffusion glass, and reduced transparency of the glass layer, so as to prevent aging changes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The light-reflecting substrate, the substrate for mounting a light-emitting element, and the light-emitting device of the present invention will be described with reference to the drawings. In addition, in the following description, the reflectance of light (visible light) may be simply called reflectance.

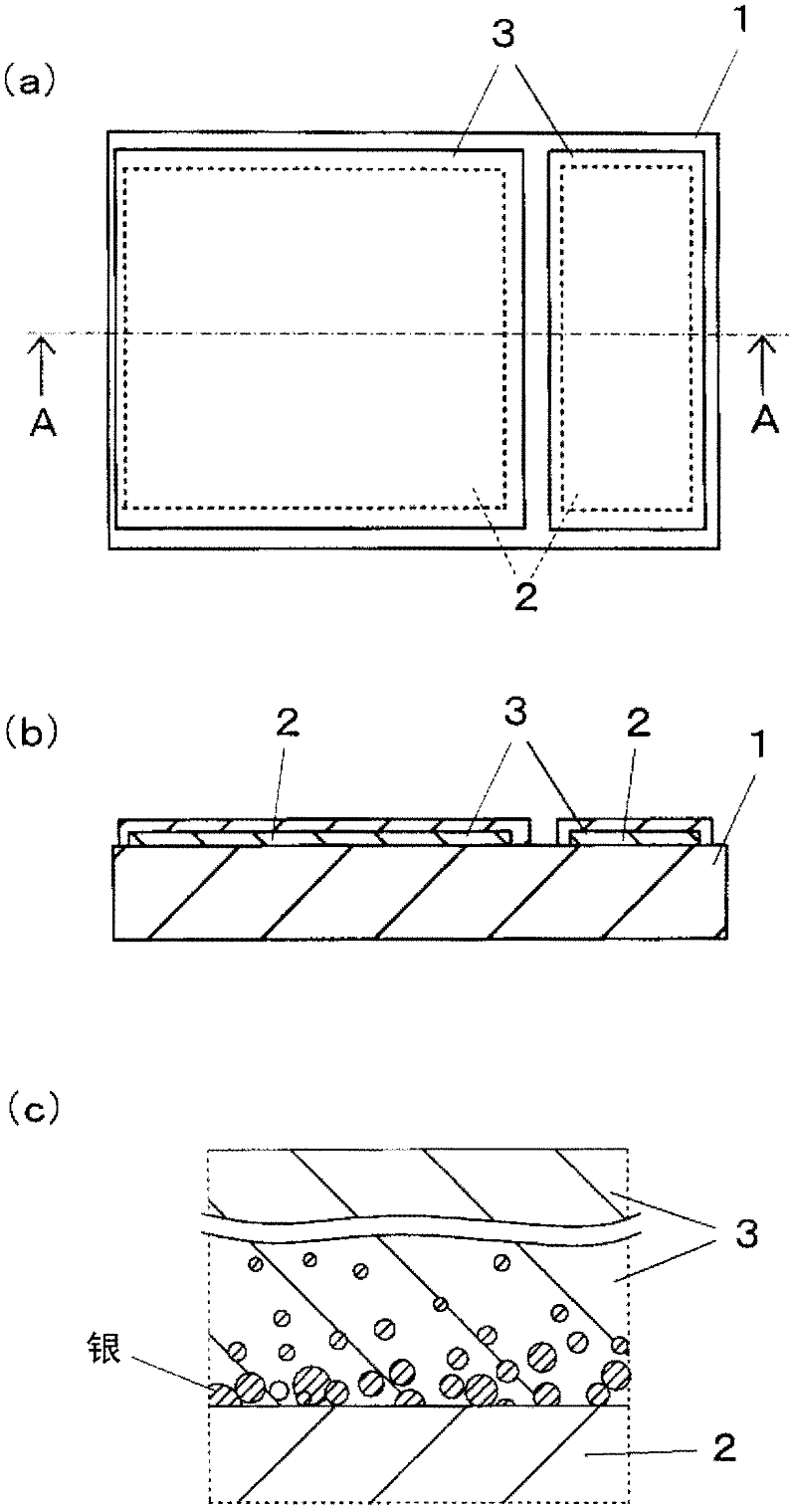

[0052] figure 1 (a) is a plan view showing an example of an embodiment of the light reflective substrate of the present invention, figure 1 (b) is figure 1 A sectional view of line A-A of (a), figure 1 (c) is to figure 1 The main part of (b) is further enlarged and a cross-sectional view schematically shown. The metal layer 2 adhered to the main surface (upper surface) of the insulating substrate 1 is covered with the glass layer 3, basically forming a light reflection substrate.

[0053] The light-reflecting substrate 1 is used in various applications for reflecting light, such as a substrate for mounting a light-emitting element for mounting a light-emitting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com