High-homogeneity bracket used for tissue engineering and preparation method of high-homogeneity bracket

A tissue engineering and uniform technology, applied in the field of biomedical engineering, can solve the problems of pore shape, size and porosity, no literature reports, easy cracking of tubular scaffolds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Preparation of 3 cm long and 1 cm diameter PHBV (polyhydroxyalkanoate) columnar porous scaffolds

[0027] 1. Solution preparation: Prepare a chloroform solution with a mass concentration of 5% PHBV, seal it and place it for use;

[0028] 2. Mold preparation: Cut the PET sheet into a strip of 5cm×4cm, and then glue it into a 5cm tube with a diameter of 1cm.

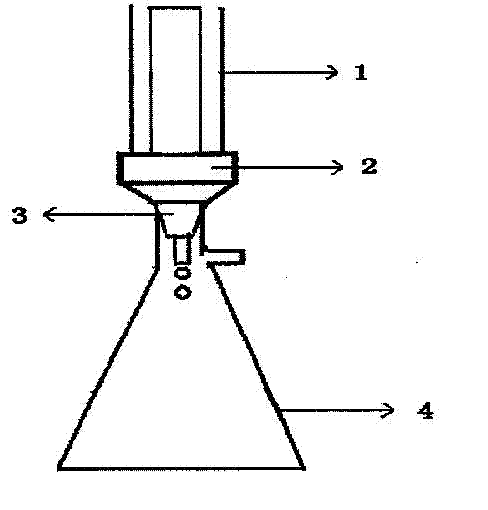

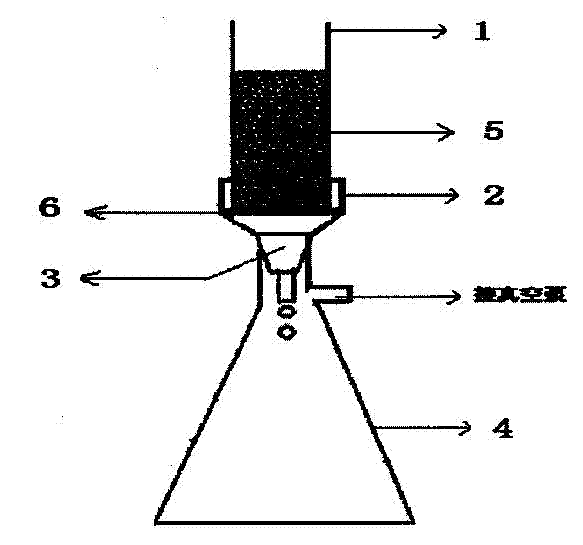

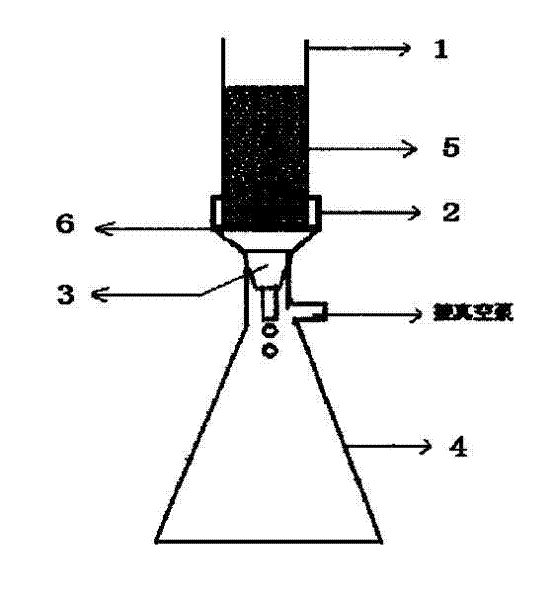

[0029] 3. Equipment installation: Lining a layer of filter paper of a suitable size at the bottom of the Buchner funnel with a diameter of 2 cm, then the tube prepared in 2 was fixed inside the Buchner funnel and sealed with tape. Then fix the Buchner funnel with a rubber stopper on a suction flask with a volume of 100ml; connect the suction flask to a vacuum pump.

[0030] 4. Fill the 2 / 3 volume of the tube with NaCl particles with a particle size of 100-150um, then continuously and slowly inject the polymer solution prepared in 1 from the opening of the mold tube, and vacuum until the polymer solution begins ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com