Manual tripping device of marine motor brake

A manual release and marine motor technology, applied in the direction of brake actuators, mechanical equipment, gear transmission mechanisms, etc., can solve the problems of not meeting the protection level, many operating actions, and no sealing structure, etc., to achieve simple structure, low cost, Create easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

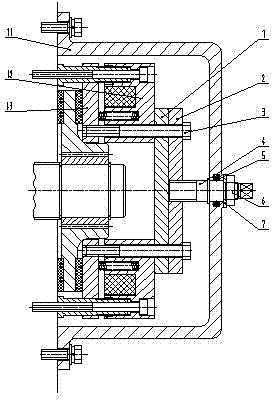

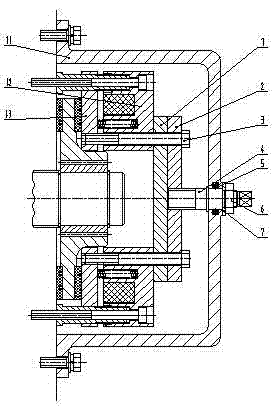

[0015] The marine motor brake manual release device shown in the accompanying drawings is a screw-driven lever translation mechanism consisting of a screw mechanism and a translation mechanism; the translation mechanism includes a support plate 1, an adjustment plate 2, a connecting bolt 3 and an armature 1.3, two The connecting bolts 3 pass through the holes on both sides of the central axis of the adjusting plate 2, the supporting plate 1, and the brake electromagnet 1.2 to connect with the armature 1.3, and connect the supporting plate 1 and the adjusting plate 2 to the shaft end of the motor brake electromagnet 1.2. The distance from the bolt 3 to the adjusting screw 4 is equal; a screw mechanism is provided at the center of the shaft end of the brake housing 1.1, and the screw mechanism includes an adjusting screw 4, a washer 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com