Method for rapidly testing service life of flexible tube and test bed thereof

A technology of test bench and hose, which is applied in the direction of testing material strength by applying stable torsion force, testing material strength by applying repetitive force/pulsation force, and testing material strength by applying stable tension/pressure, which can solve time-consuming and expensive problems. Test and other issues to achieve the effect of shortening test time and test cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

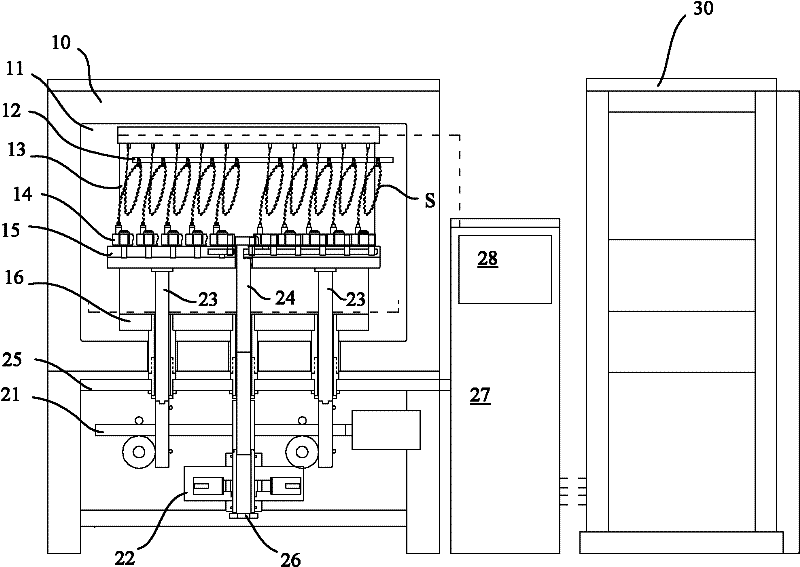

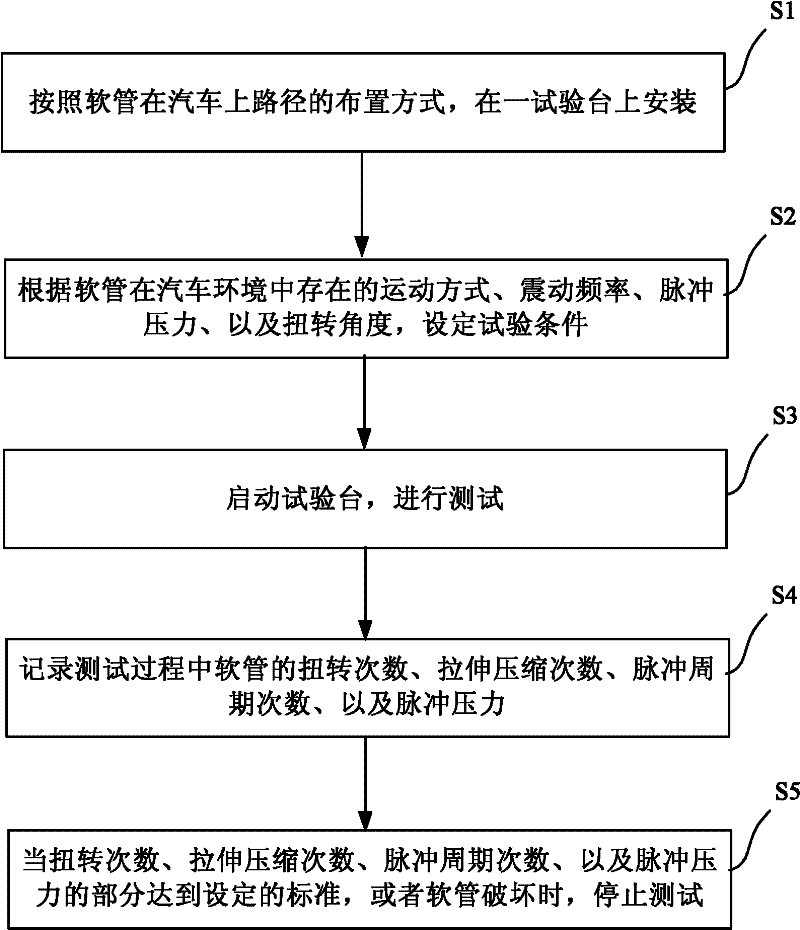

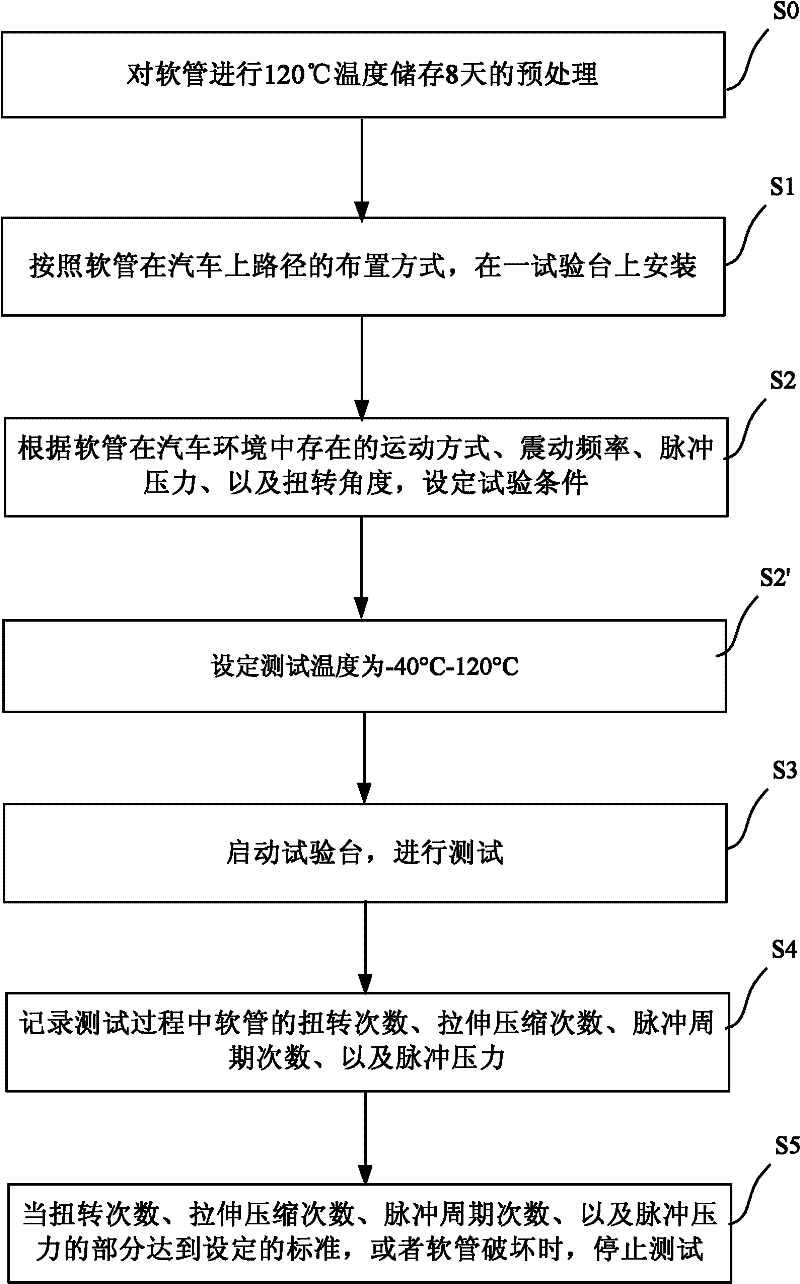

[0025] According to the concept of the present invention, the following method for quickly testing the life of the hose is provided. The method simulates the environment of the hose on the car, and accelerates the aging of the hose through a higher-intensity test, thereby greatly shortening the test time.

[0026] Figure 2A The flow chart of the hose test method according to an embodiment of the present invention is shown. refer to Figure 2A As shown, the methods include:

[0027] Step S1, installing on a test bench according to the layout of the hose on the vehicle;

[0028] Step S2, according to the movement mode, vibration frequency, pulse pressure, and torsion angle of the hose in the automobile environment, set the torsion angle, torsion speed, compression and stretch displacement, stretch speed, pulse pressure, and pulse period;

[0029] Step S3, start the test bench for testing;

[0030] Step S4, recording the twisting times, stretching and compressing times, puls...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com