Grating coupler and coupling structure and packaging structure of grating coupler and optical fibers

A technology of grating coupler and coupling structure, which is applied in the coupling of optical waveguide and other directions, and can solve the problems of optical fiber alignment and positioning that have not been effectively solved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

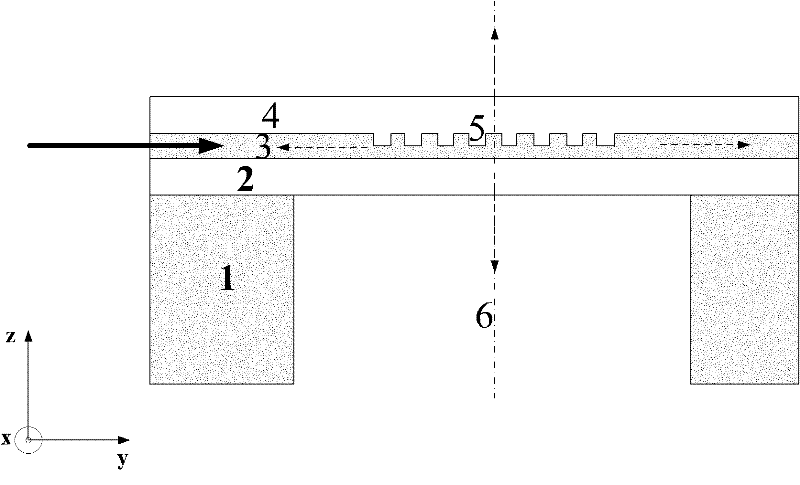

[0021] Such as figure 1 As shown, the schematic diagram of the basic structure of the grating coupler with silicon substrate layer etching holes provided by the embodiment of the present invention;

[0022] The grating coupler on the SOI substrate is: the silicon substrate layer 1 of the SOI substrate, the silicon dioxide intermediate layer 2 of the SOI substrate from bottom to top, the silicon top layer 3 of the SOI substrate and the upper cladding layer 4 to form a vertical optical The waveguide structure, the optical coupling grating 5 located on the silicon top layer 3 of the SOI substrate, and the etching hole 6 are etched on the silicon substrate layer 1 of the SOI substrate. The etching hole 6 is formed by dry etching. During the dry etching process, the silicon dioxide intermediate layer 2 of the SOI substrate becomes an etching stopper layer, that is, the etching hole 6 passes through the silicon substrate layer 1 of the SOI substrate. It ends at the lower surface of...

Embodiment 2

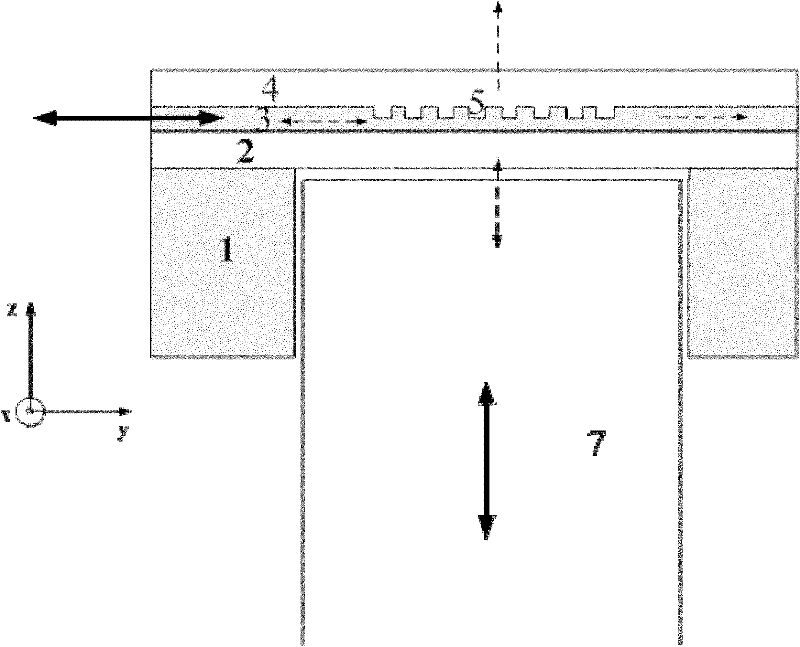

[0024] Such as figure 2 As shown, the embodiment of the present invention provides a schematic diagram of the coupling structure of the grating coupler with the silicon substrate layer etching hole and the optical fiber;

[0025] The grating coupler on the SOI substrate is that the silicon substrate layer 1 of the SOI substrate, the silicon dioxide intermediate layer 2 of the SOI substrate from bottom to top, the silicon top layer 3 of the SOI substrate and the upper cladding layer 4 constitute a vertical optical The waveguide structure, and the optical coupling grating 5 located on the silicon top layer 3 of the SOI substrate, and the silicon substrate layer 1 of the SOI substrate are etched with an etching hole 6, and the axis of the etching hole 6 coincides with the center of the optical coupling grating 5 Inserting the optical fiber 7 into the etched hole 6 realizes the self-alignment and positioning of the optical coupling grating and the optical fiber. The positioning ...

Embodiment 3

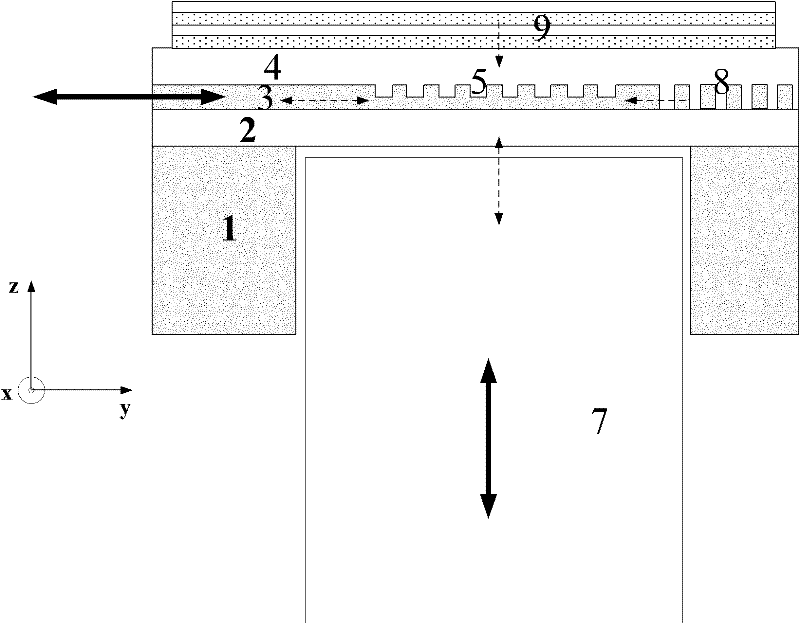

[0027] Such as image 3 As shown, the embodiment of the present invention provides a grating coupler with a silicon substrate layer etching hole, a back grating and a top grating, and a schematic diagram of its coupling structure with an optical fiber;

[0028] In order to reduce the light energy leakage loss along the back direction after the light wave is diffracted by the optical coupling grating 5 in the optical waveguide structure and the light energy leakage loss that is emitted upward after the light wave is diffracted by the optical coupling grating 5, the designed silicon substrate layer engraved grating coupler for pitting, back grating and top grating,

[0029] The grating coupler on the SOI substrate is that the silicon substrate layer 1 of the SOI substrate, the silicon dioxide intermediate layer 2 of the SOI substrate from bottom to top, the silicon top layer 3 of the SOI substrate and the upper cladding layer 4 constitute a vertical optical The waveguide struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com