Dividing type electronic voltage transformer of three-phase capacitor

A technology of voltage transformer and capacitor voltage division, which is applied in the direction of voltage divider, inductor, transformer, etc., can solve the problems of poor shielding and anti-interference ability, complex structure of transformer, large volume, etc., achieve good shielding effect and reduce tip The effect of discharge and volume change is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

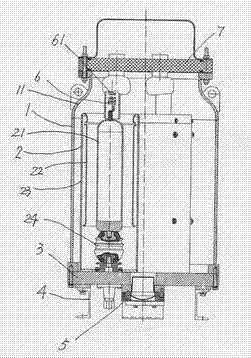

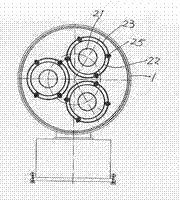

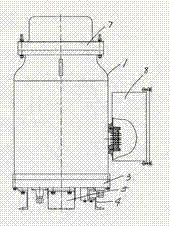

[0022] Refer to attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 , attached Figure 5 , attached Figure 6 , a three-phase capacitive voltage dividing type electronic voltage transformer of the present invention consists of a housing 1, three sets of electrode devices 2, a base 3, a bracket 4, an explosion-proof device 5, a connecting cable 6, a pot insulator 7, and a lead device 8 Composition, three sets of electrode devices 2 are arranged on the base 3, and a casing 1 connected with the base 3 is arranged on the periphery of the three sets of electrode devices 2, and the casing 1 is made of aluminum alloy with low expansion coefficient The metal cylinder, the upper port 11 of the shell 1 is an arc-shaped structure; the electrode device 2 of the three groups is composed of a high-voltage electrode 21, a medium-voltage electrode 22, a ground electrode 23, a support insulation 24, and an insulation support shaft. The support insulation 24 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com