Manufacture method of carbon brush, manufacture method of carbon rod and carbon brush

A manufacturing method and carbon rod technology, applied in brush manufacturing, current collectors, electrical components, etc., can solve problems such as inaccurate measurement, and achieve the effects of improving measurement accuracy, avoiding wear, and reducing friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

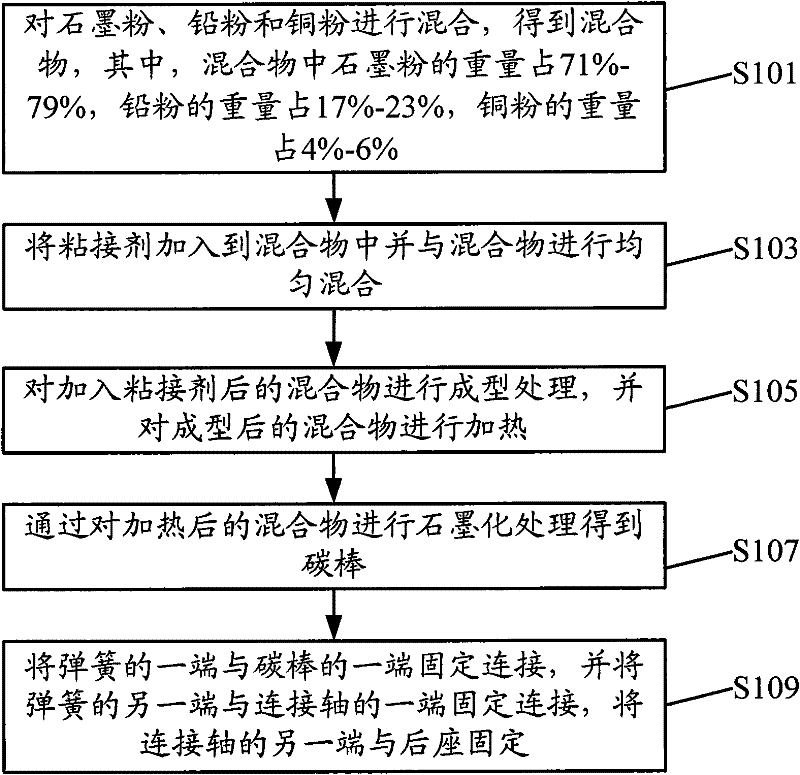

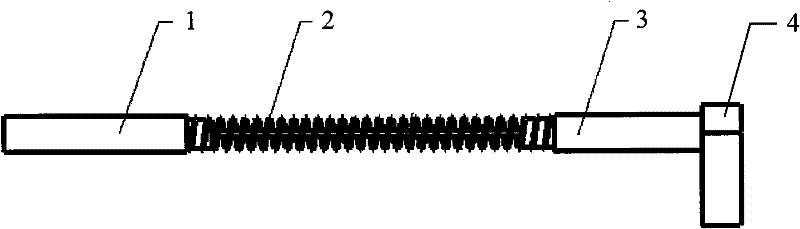

[0026] Aiming at the problem of inaccurate measurement due to carbon brush wear, the impedance of the carbon brush itself, and poor contact of the carbon brush in the related art, the present invention proposes a method for manufacturing a carbon brush, wherein, in the manufacture and aerostatic electric spindle, When a high-speed rotating shaft such as an electric spindle contacts a carbon rod, a certain proportion of graphite powder, copper powder, and lead powder is used, so that not only can the carbon rod have a certain rigidity, but also can reduce the impedance of the carbon rod and carbon The friction coefficient between the rod and the rotating shaft can effectively improve the measurement accuracy, prolong the life of the carbon brush, and prevent the carbon brush from wearing the main shaft.

[0027] A method of manufacturing a carbon brush according to an embodiment of the present invention will be described in detail below.

[0028] The carbon brush manufactured b...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap