Diamond Wire Saw

A technology of diamond wire saw and diamond particles, which is applied in the direction of metal sawing equipment, stone processing equipment, stone processing tools, etc., can solve the problem of not considering the optimization range, and achieve the effect of suppressing shedding and increasing cutting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings, but the same reference numerals will be assigned to the same parts as conventional members, and detailed description will be omitted.

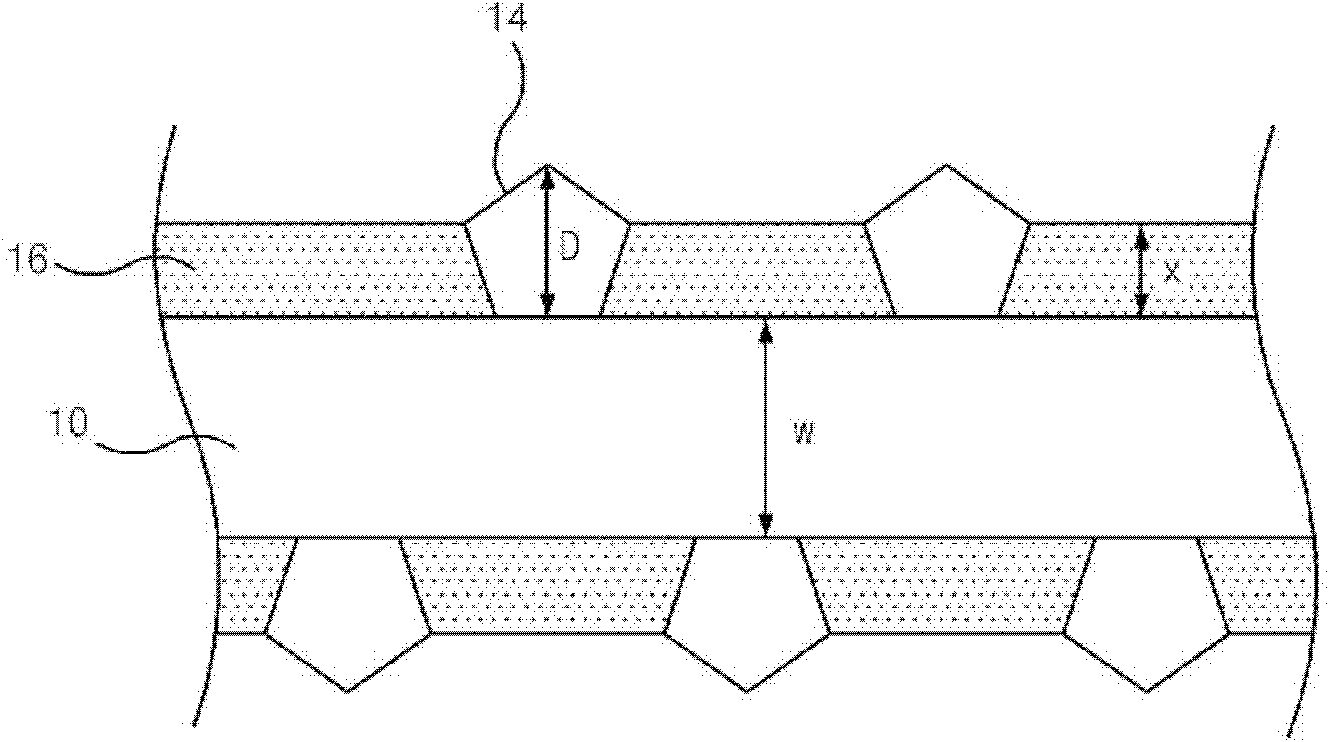

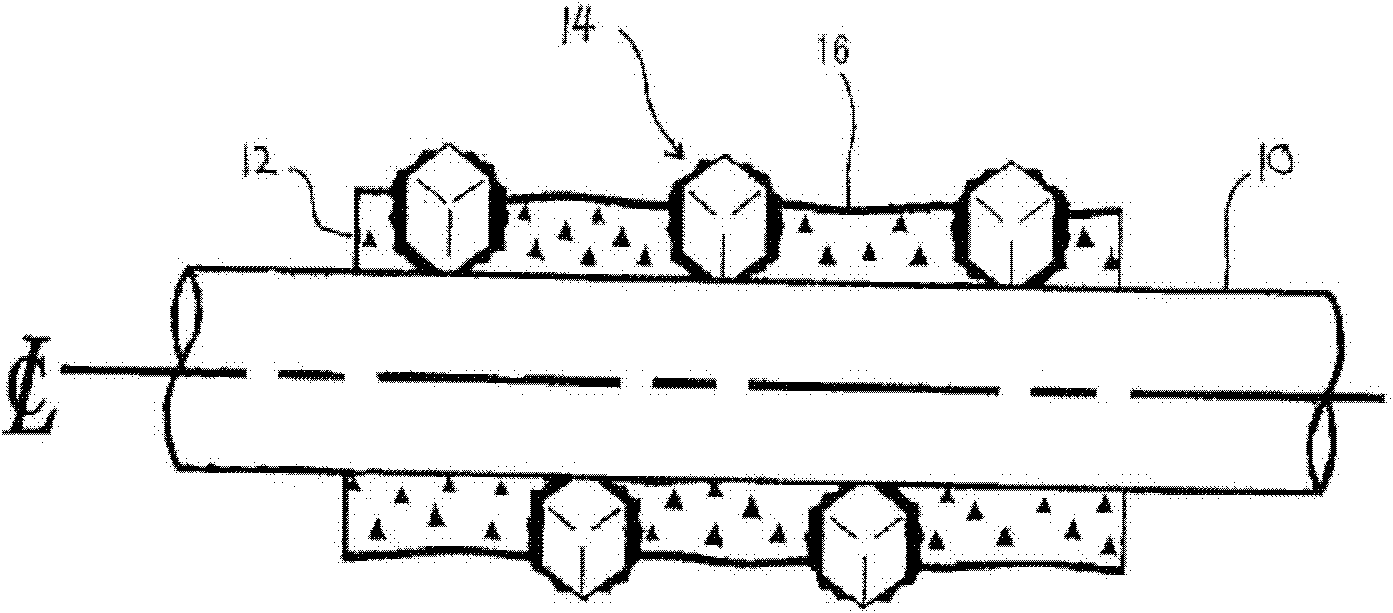

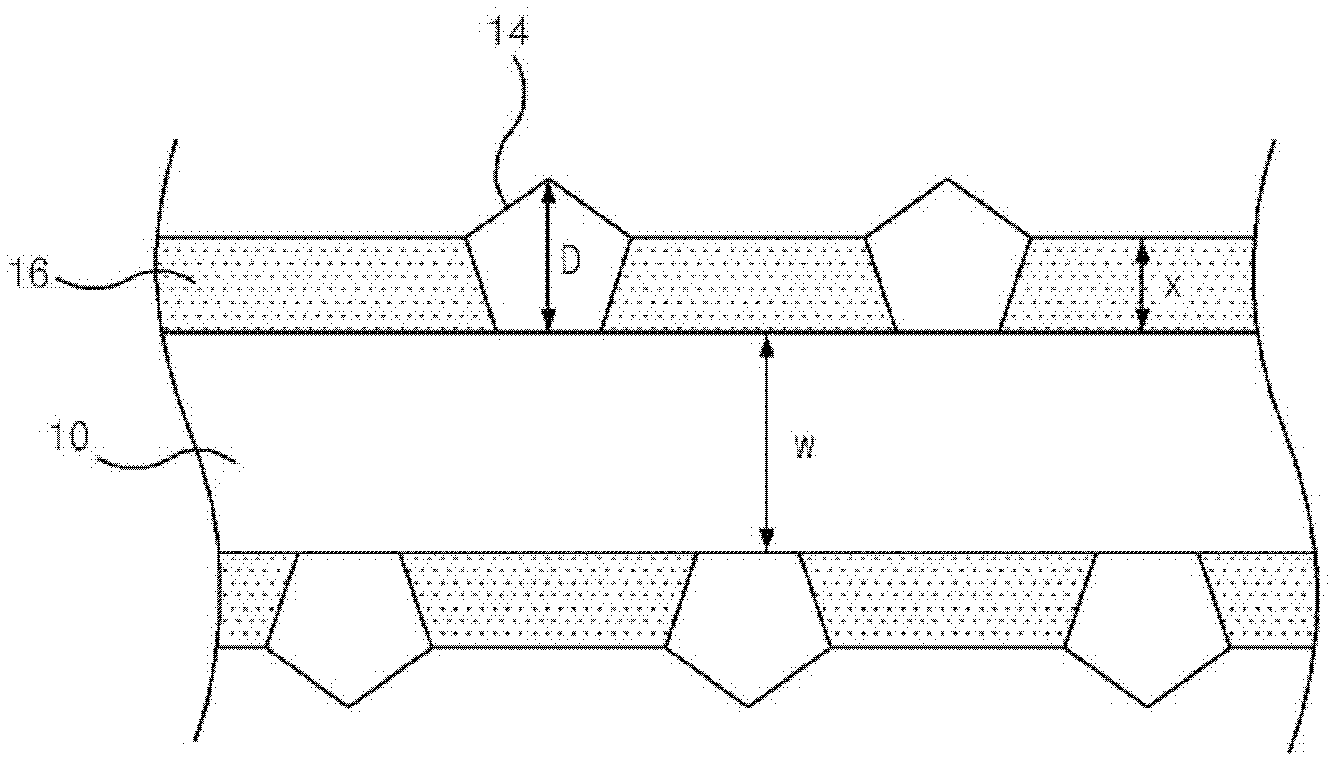

[0027] figure 1 is a longitudinal sectional view of a diamond wire saw for explaining the correlation between the cable, the nickel plating layer, and the diamond particles according to a preferred embodiment of the present invention.

[0028] Such as figure 1 As shown, the wire saw based on the embodiment of the present invention is the same as the existing products, and is composed of the following members, that is, a cable 10 having a predetermined length, a plurality of diamond particles 14, and the diamond particles 14 are combined and supported on the cable 10. The binding agent 16.

[0029] At this time, the bonding agent 16 is preferably embodied as an electroplated nickel layer 16 in order to maintain a height for f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com