Arrangement having an electric machine and method for operating an electric machine

A thermopile and rotor technology, applied in electromechanical devices, measuring devices, electric components, etc., can solve the problems of temperature detection distortion, measurement distortion, impossible multiple positions of the structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

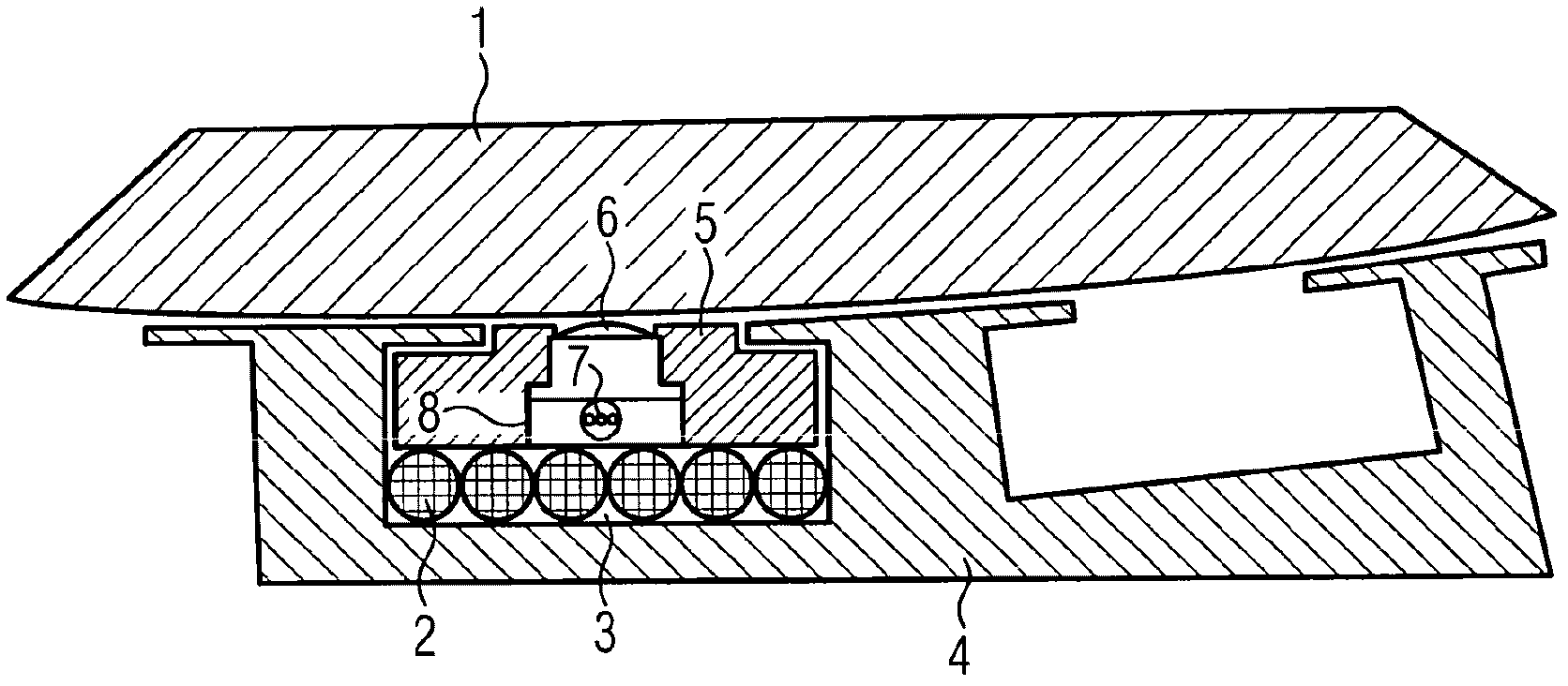

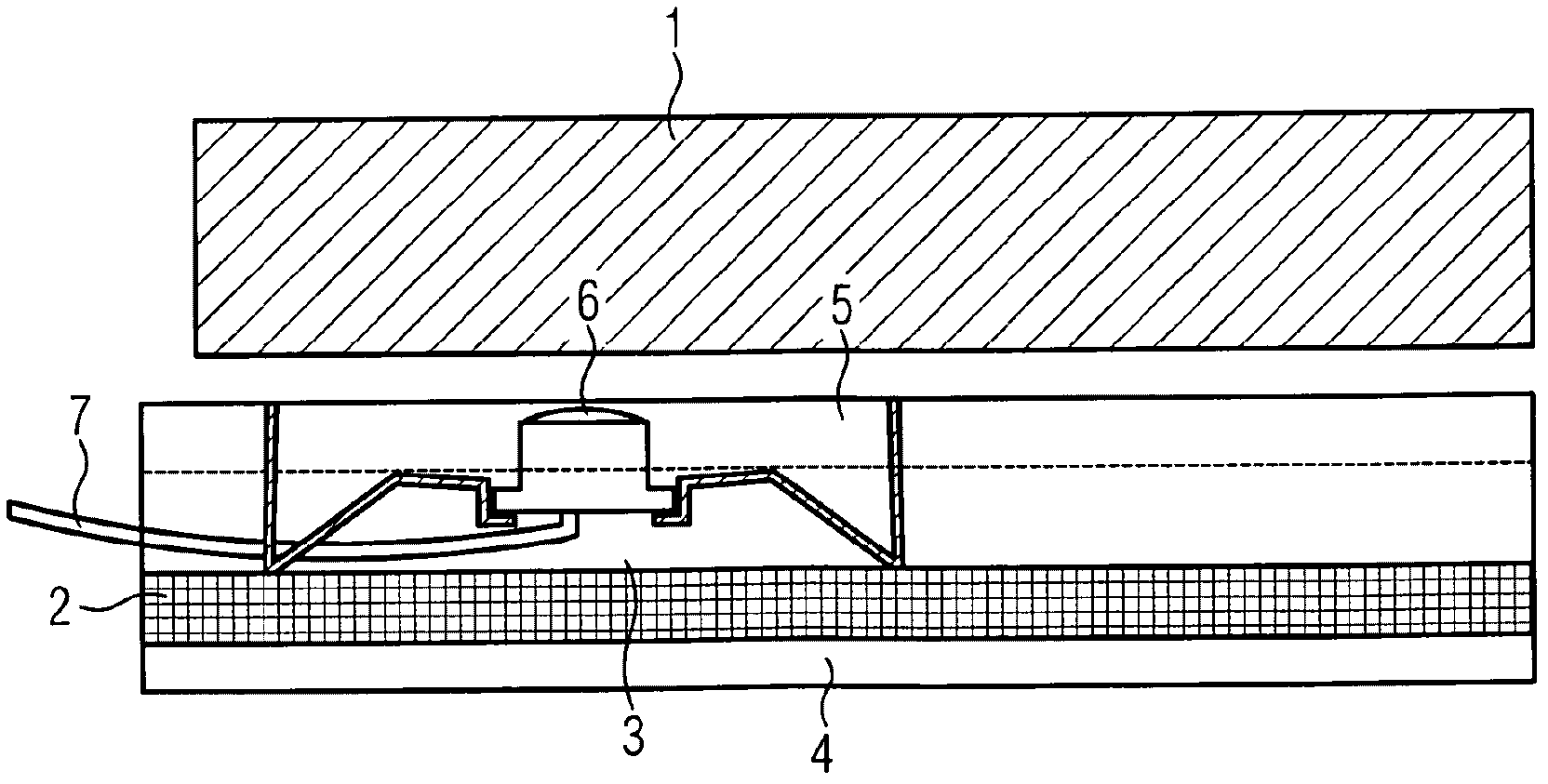

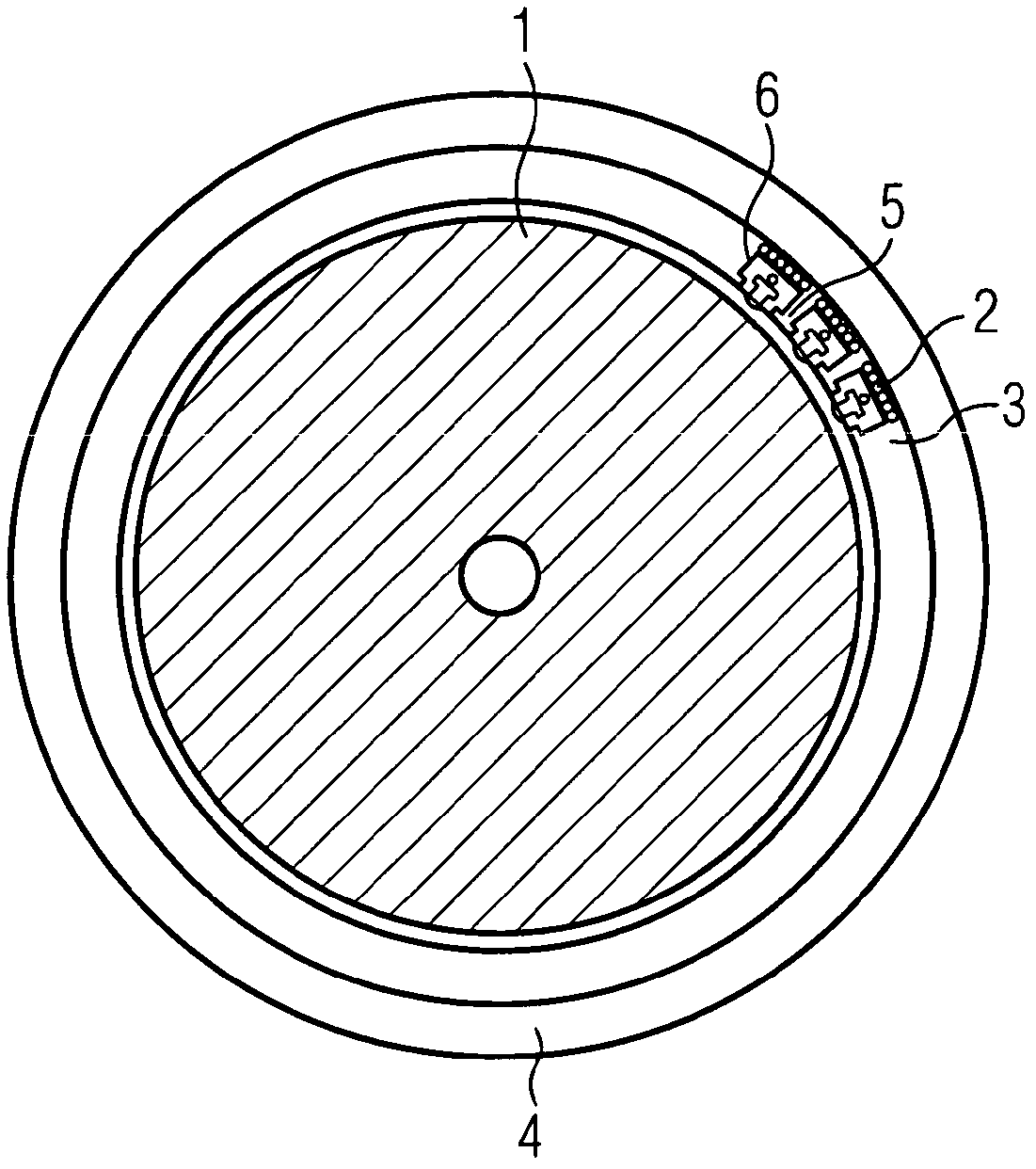

[0021] exist figure 1 A schematic sectional view (cross section) of a section of an electric machine with rotor 1 and stator 4 is shown in . A slot 3 is provided in the stator, in which slot the winding 2 of the stator 4 runs. For clear reasons, in figure 1Only 6 coil layers with winding 2 are shown in . In the slot closing wedge 5 of the slot 3 is introduced a deep hole 8 which is completely filled with a thermopile 6 (infrared temperature sensor). The deep hole 8 has a through-opening at the rotor 1, into which the detection side of the thermopile 6 protrudes, wherein on this side the side of the thermopile 6 consists of a transparent plastic which Has a lens-shaped surface. Since the through holes have a smaller diameter than the deep holes, the deep holes 8 are provided with a depth limit that prevents the thermopile 6 from falling into the air gap between the rotor 1 and the stator 4 . The thermopile 6 rests firmly against the winding 2 on the winding 2 , so that it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com