Optical temperature sensor

A fiber optic temperature and sensor technology, applied in thermometers, instruments, optics, etc., can solve the problems of high grating price and complicated equipment, and achieve the effect of reducing setting space, reducing constraints, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Hereinafter, the optical fiber temperature sensor of the preferred embodiment of the present invention will be described in more detail with reference to the accompanying drawings.

[0051] First, an optical fiber temperature sensor according to a first embodiment of the present invention will be described.

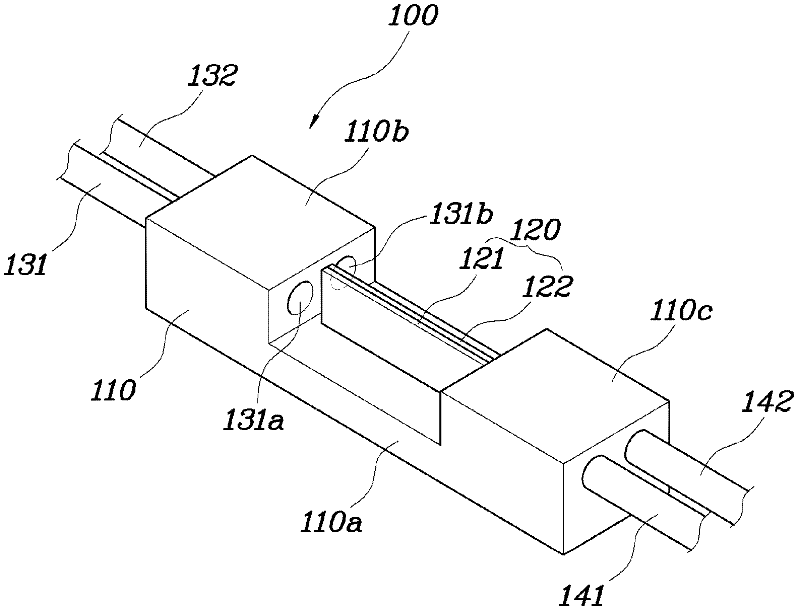

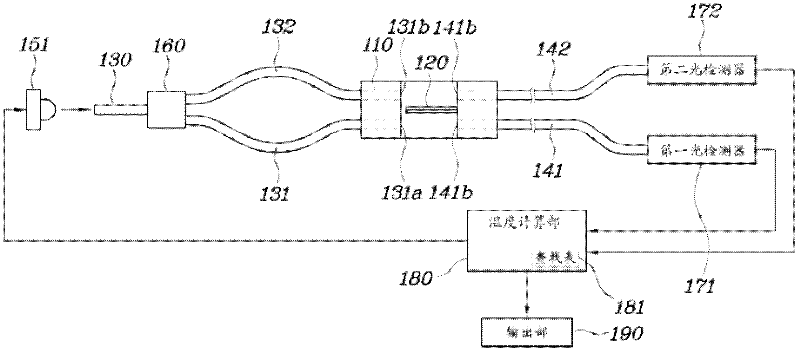

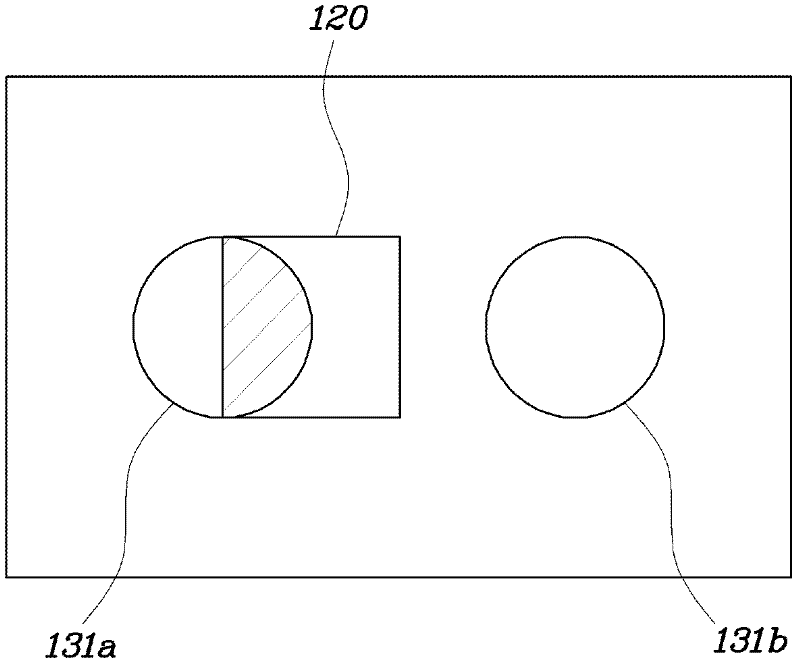

[0052] figure 1 It is a perspective view of the optical fiber temperature sensor of the present invention. figure 2 for figure 1 The circuit diagram of the control system of the fiber optic temperature sensor.

[0053] Such as figure 1 and figure 2 As shown, the fiber optic temperature sensor 100 includes: a housing 110, a bimetal element 120, a light source 151, an optical splitter 160, a first input fiber 131 and a second input fiber 132, a first output fiber 141 and a second output The end optical fiber 142 , the first photodetector 171 and the second photodetector 172 , and the temperature calculation unit 180 .

[0054] The housing 110 has a structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com