Non-aqueous electrolytic solution, and non-aqueous electrolyte battery comprising same

A non-aqueous electrolyte, non-aqueous technology, applied in non-aqueous electrolyte batteries, electrolytes, lithium batteries, etc., can solve problems such as no clear records, and achieve the effect of improving continuous charging characteristics and improving overcharging characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

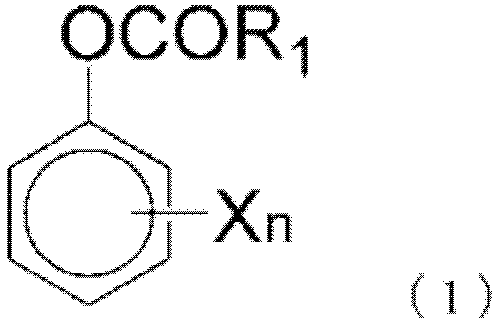

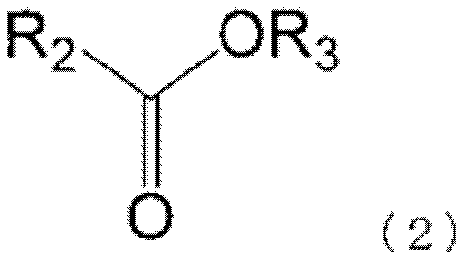

Embodiment 1

[0398] In a mixed solvent of ethylene carbonate (EC) as a saturated cyclic carbonate, dimethyl carbonate (DMC) as a chain carbonate, and ethyl methyl carbonate (EMC) (mixing volume ratio 2:7:1) In the 1mol / L ratio, LiPF as the electrolyte 6 After dissolving, 4-fluorophenyl acetate and vinylene carbonate (VC) were added so as to make them 2% by weight with respect to the total weight of the electrolytic solution, respectively, to prepare a non-aqueous electrolytic solution. Using the obtained non-aqueous electrolytic solution, a lithium secondary battery was manufactured according to the above-mentioned method, and a capacity evaluation test, an overcharge characteristic evaluation test, and a storage characteristic evaluation test were performed. The results are shown in Table 1.

Embodiment 2

[0400] In a mixed solvent of ethylene carbonate (EC), propylene carbonate (PC) as a saturated cyclic carbonate, and dimethyl carbonate (DMC) as a chain carbonate (mixing volume ratio 2:1:7 ), LiPF as electrolyte is made at a ratio of 1mol / L 6 After dissolving, 4-fluorophenyl acetate and vinylene carbonate (VC) were added so as to make them 2% by weight with respect to the total weight of the electrolytic solution, respectively, to prepare a non-aqueous electrolytic solution. Using the obtained non-aqueous electrolytic solution, a lithium secondary battery was manufactured according to the above-mentioned method, and a capacity evaluation test, an overcharge characteristic evaluation test, and a storage characteristic evaluation test were performed. The results are shown in Table 1.

Embodiment 3

[0402] In a mixed solvent of ethylene carbonate (EC) as a saturated cyclic carbonate, dimethyl carbonate (DMC) as a chain carbonate, and ethyl methyl carbonate (EMC) (mixing volume ratio 2:7:1) In the 1mol / L ratio, LiPF as the electrolyte 6 After dissolving, 4-fluorophenyl acetate and vinylene carbonate (VC) were added so as to make them respectively 4% by weight and 2% by weight relative to the total weight of the electrolyte solution to prepare a non-aqueous electrolyte solution. Using the obtained non-aqueous electrolytic solution, a lithium secondary battery was manufactured according to the above-mentioned method, and a capacity evaluation test, an overcharge characteristic evaluation test, and a storage characteristic evaluation test were performed. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com