Method for manufacturing drum blank

A blank and wood type technology, which is applied in the field of making drum blanks, can solve the problems of no machining allowance on both sides of the key parts, difficulty in repairing and processing, and affecting the production cycle, so as to solve the problems of easy deformation and save assembly time , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

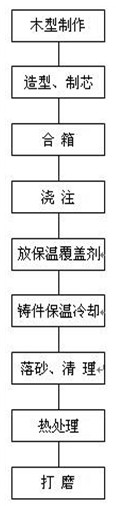

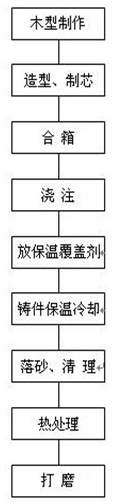

[0025] As shown in the figure, a method for making a drum blank includes the following steps:

[0026] 1) Make wood molds and core boxes, and make wood molds according to the castings that make double-layer ties at the bottom and middle; wood molds make six core boxes, and make 1 core, core 2, core 3, and core 6 / 4 core boxes, change the loose pieces, and mark them separately;

[0027] 2) Modeling and core making, after the wood type is made, start modeling and core making;

[0028] 3) Close the box, paint the core to close the box after the core is assembled;

[0029] 4) Pouring, pouring in time after closing the box; the pouring temperature is 1570°C, and the pouring time is 150S. During the pouring process, slow down and pour when pouring reaches one-third of the riser;

[0030] 5) Put the thermal insulation covering agent; the initial additi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com