Bottom chord tube manufacturing process of girder of steel tube concrete truss beam bridge

A production process and steel pipe technology, applied in the direction of manufacturing tools, metal processing equipment, arc welding equipment, etc., to ensure the quality and efficiency of welding seam welding, reduce manual welding workload and welding deformation, and ensure the effect of welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

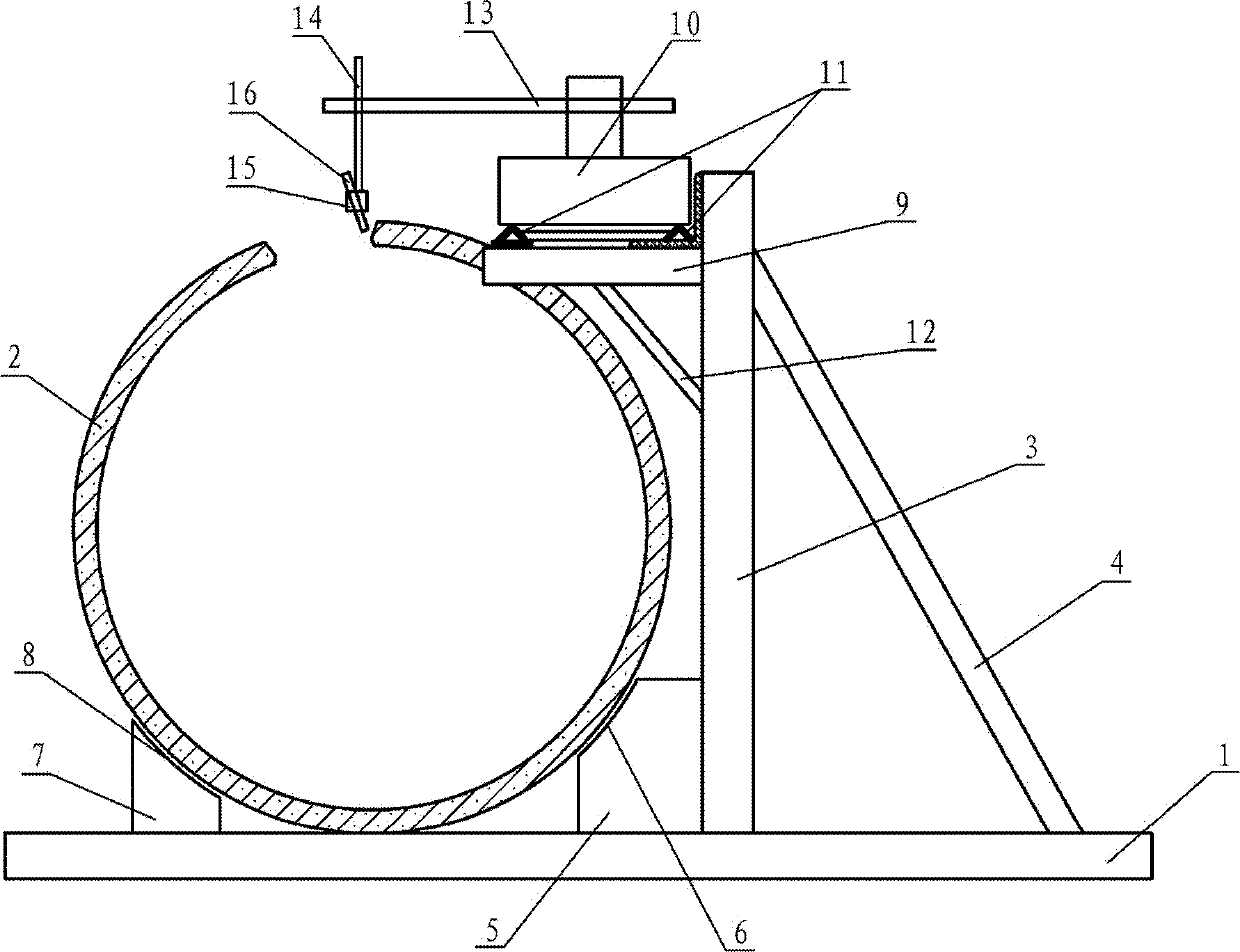

[0031] Hereinafter, exemplary embodiments of the present invention will be described in detail with reference to the drawings. However, the present invention may be implemented in many different forms, and should not be construed as being limited to the exemplary embodiments set forth herein.

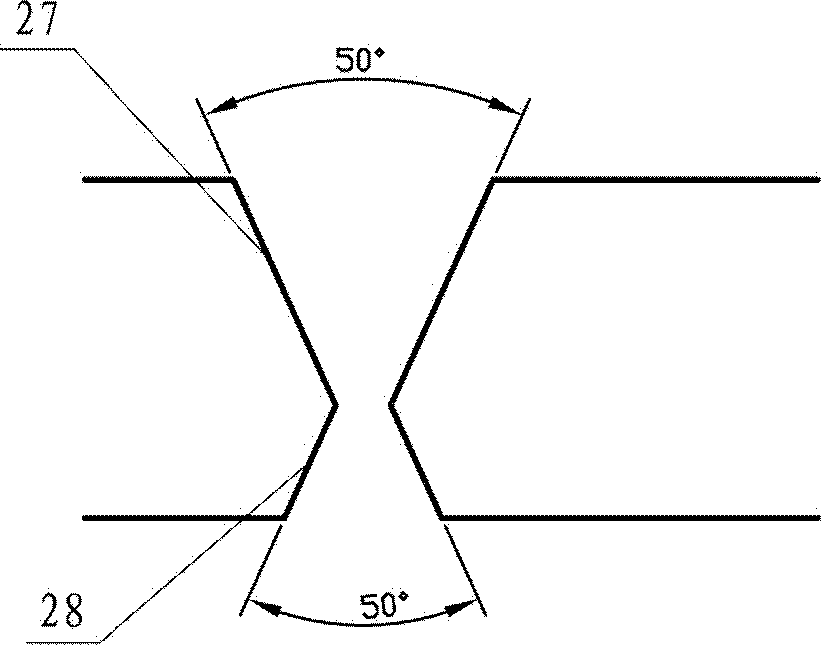

[0032] In the production process of steel pipes, considering that steel pipes with wall thicknesses of δ=28mm and δ=32mm are the most difficult to roll, in the following, steel pipes with thicknesses of δ=28mm and δ=32mm are taken as examples for description.

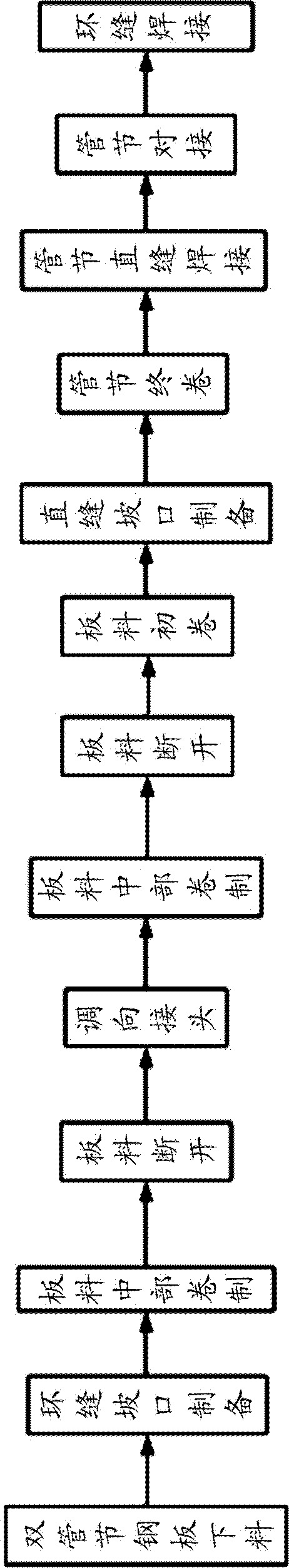

[0033] figure 1 It is a flowchart of a manufacturing process of a steel pipe according to an exemplary embodiment of the present invention.

[0034] Such as figure 1 As shown in the figure, the manufacturing process of the steel pipe (for example, the lower chord of the main girder of a steel pipe concrete truss girder bridge) according to an exemplary embodiment of the present invention includes the following steps:

[0035] (1) Prepare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com