Lower grinding head tray structure of vertical grinder

A vertical grinding machine and pallet technology, applied in the field of metal cutting processing, can solve the problems of falling parts, time-consuming and laborious, affecting the production efficiency of the grinding machine, etc., and achieve the effect of ingenious conception and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

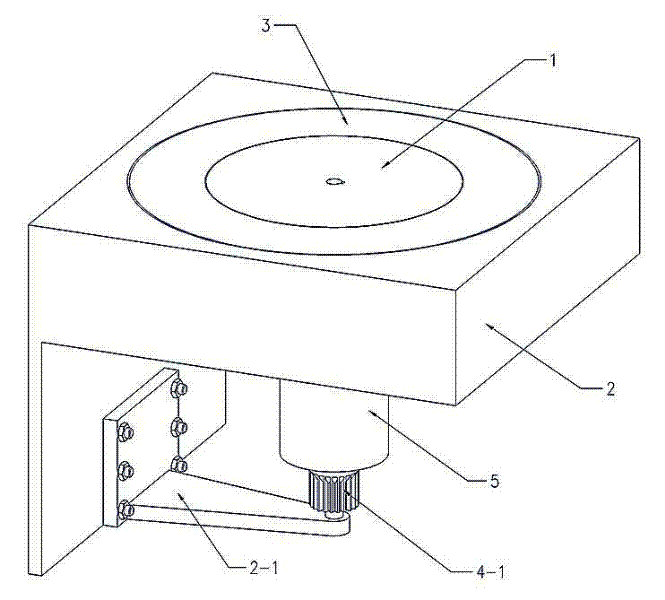

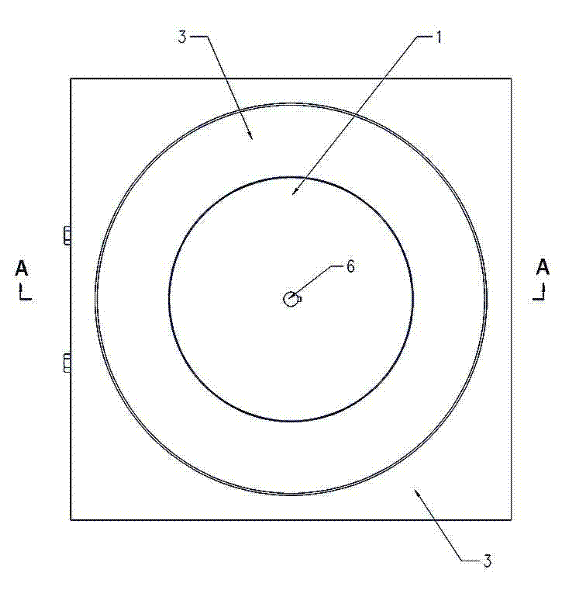

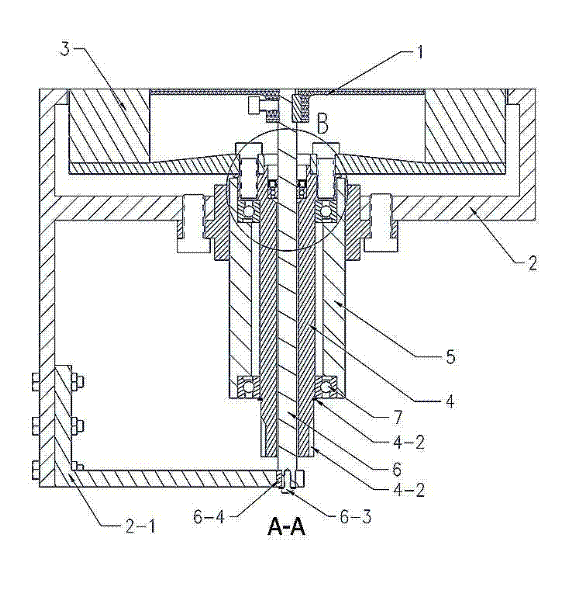

[0020] The structure of the lower grinding head tray of the vertical grinding machine is as follows: figure 1 - Figure 5 shown.

[0021] The support frame 2-1 is fixed with screws at the bottom of the frame 2, and complex parts are decomposed into several parts for assembly, which can reduce the complexity of manufacturing and metal processing, and also increase the flexibility of parts replacement. Bearing frame 2-1 is provided with axle hole and keyway, is convenient to install long shaft 6, and the lower end of long shaft 6 is inserted in the shaft hole of supporting frame 2-1, and is fixed together with flat key 6-4, and long shaft 6 Screw holes are set on the lower end surface of the tray, and the flat washers and bolts 6-3 are used as further fixation. There is also an indirect use, that is, the installation height of the long axis 6 can be adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com