Auxiliary up-and-down feeding mechanism of surface-grinding machine

A surface grinder, fixed arm technology, applied in the direction of grinding machine parts, grinding workpiece supports, grinding/polishing equipment, etc., can solve problems such as poor flexibility and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

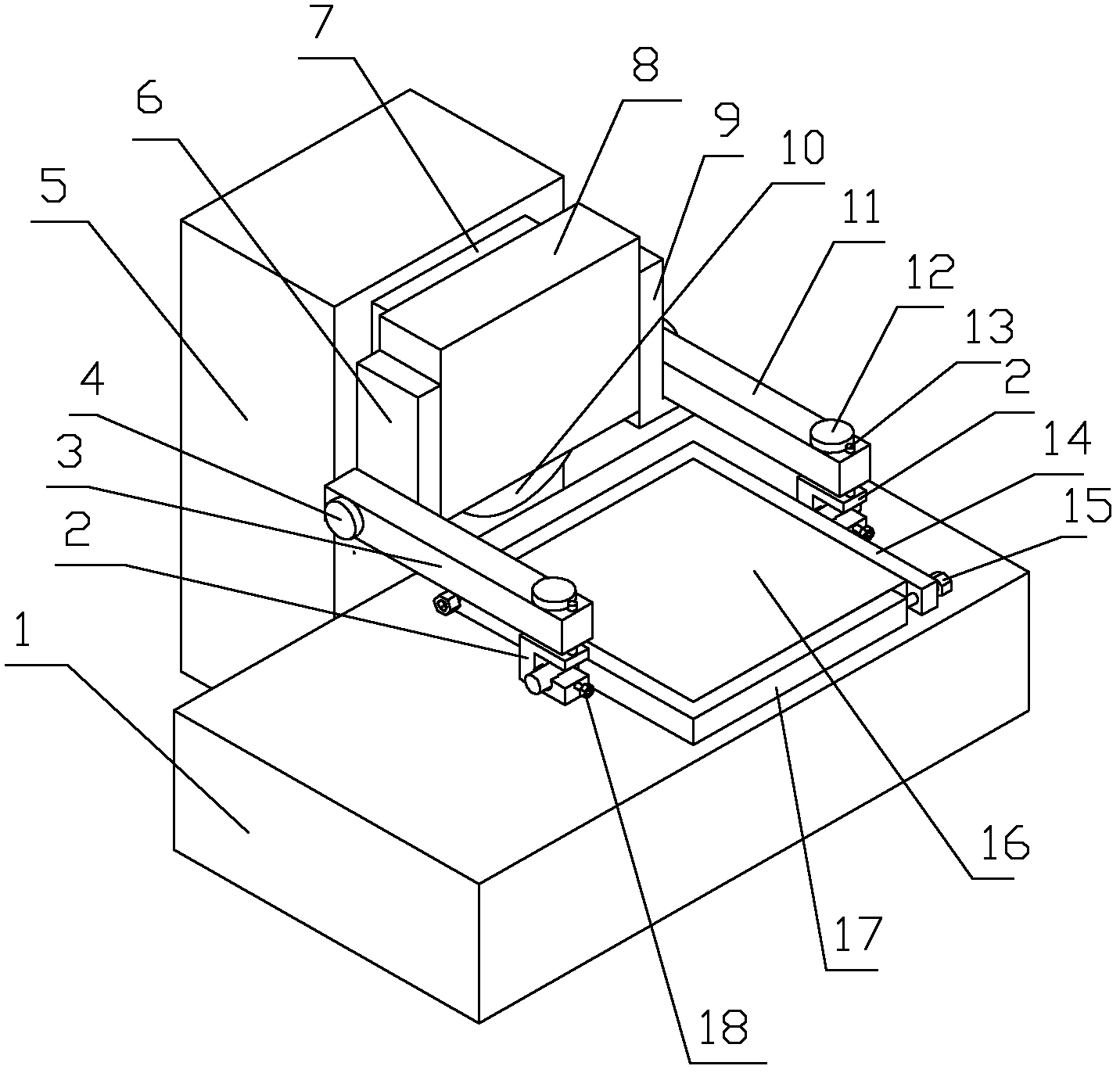

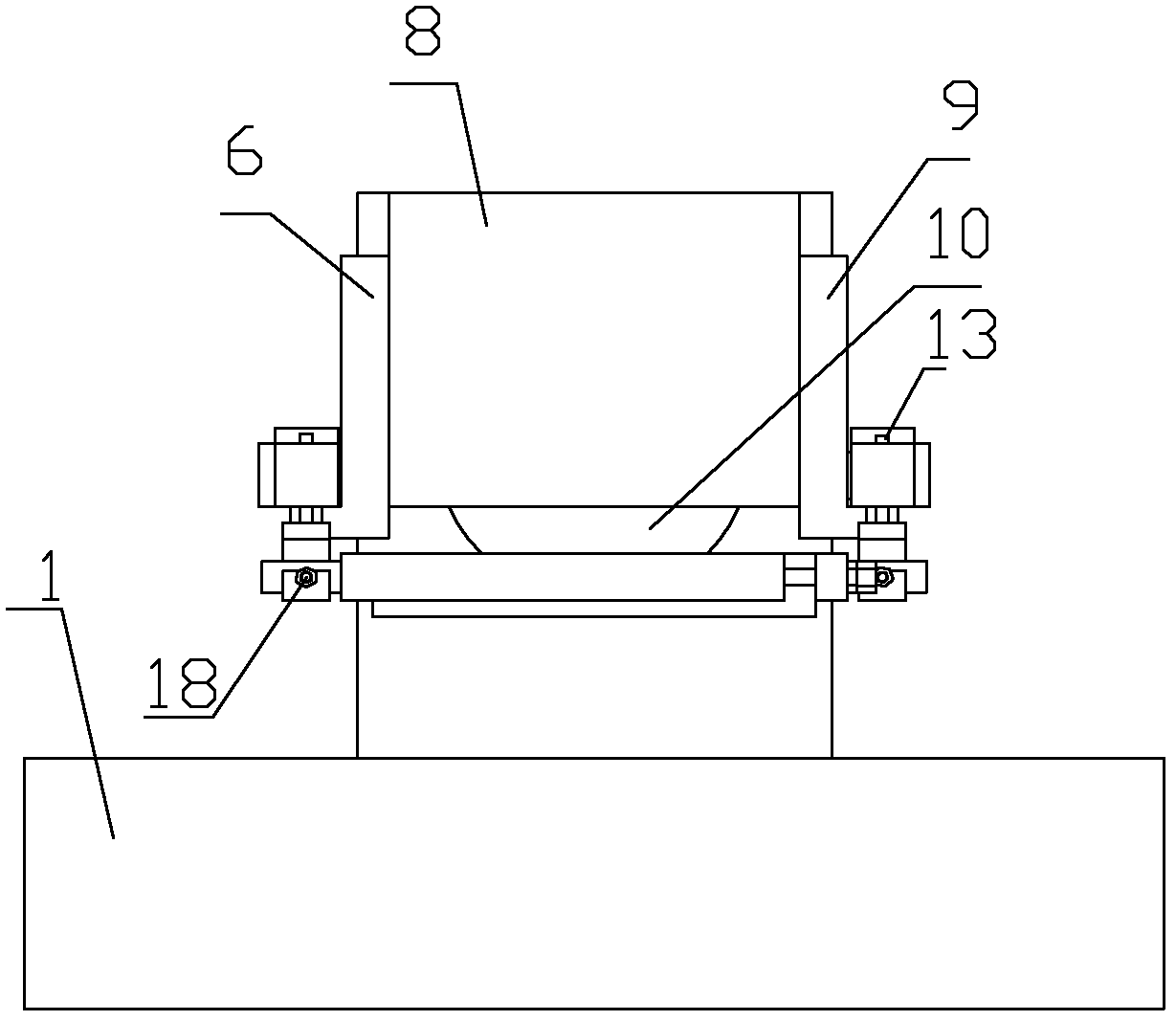

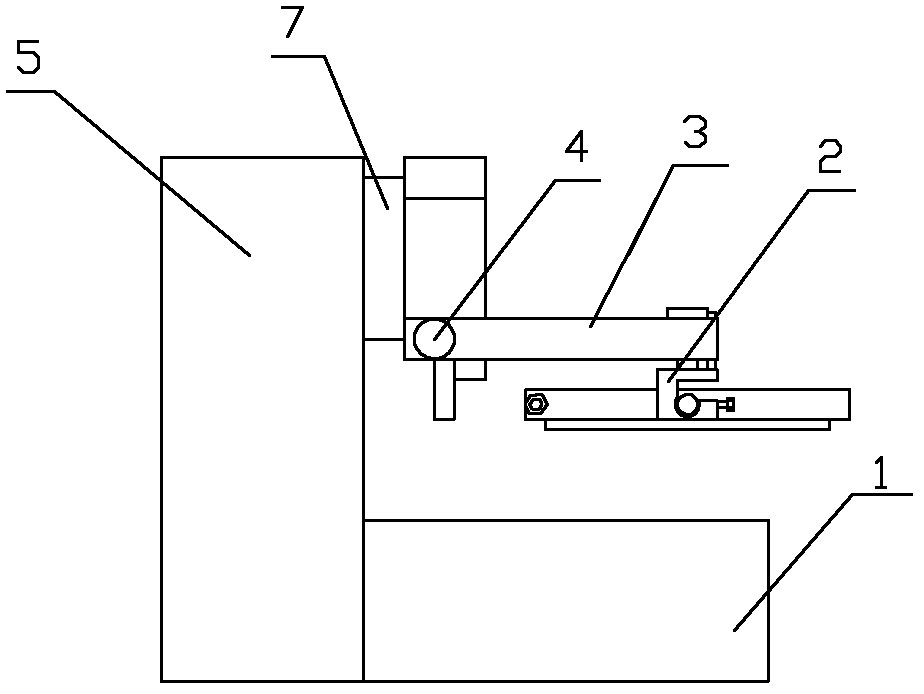

[0027] see Figure 1~6 , the embodiment of the present invention is provided with grinding machine table 1, rotating shaft block 2, left lifting arm 3, fixed arm end cover 4, grinding machine column 5, left fixed arm 6, grinding machine headstock 7, grinding wheel cover 8, right fixed arm 9, Grinding wheel 10, right lifting arm 11, rotating shaft block end cover 12, positioning pin 13, right clamping arm 14, locking screw 15, workpiece 16, left clamping arm 17, positioning screw 18.

[0028]The left fixed arm 6 and the right fixed arm 9 of the auxiliary loading and unloading mechanism are installed on the grinding wheel cover 8 both sides on the surface grinder spindle box 7 . The left lifting arm 3 and the right lifting arm 11 are all provided with round holes, which are correspondingly installed on the convex round table shafts of the left fixed ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com