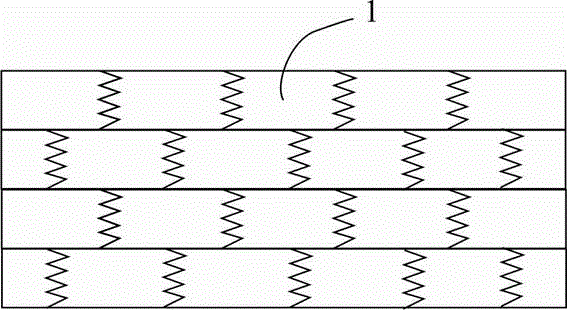

Preparation process for wedge joint boards

A preparation process and finger joint board technology, applied in the field of home decoration materials, can solve the problems of unsuitable large-scale production, high cost, complicated process, etc., and achieve the effects of small deformation, high bearing pressure and high value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0023] 1. Log cutting:

[0024] 1. The cutting of logs should follow the principle that the length of the wood is bent and the length of the wood is not bent.

[0025] 2. The material cutting worker should check whether the material cutting saw is running normally and whether the saw blade is sharp. It is strictly forbidden to operate the material cutting saw with sickness.

[0026] 3. Whether the planes at both ends of the broken wood section are consistent, there should be no slope, and the wood sections are stacked according to their diameter. (Below 12 centimeters is one category, 12-20 centimeters is one category, and over 20 centimeters is one category.)

[0027] 2. Band saw and edge trimming:

[0028] 1. Band saw workers should pay attention to check whether the band saw is running normally and whether the saw blade is sharp. It is strictly forbidden to operate the machine with a disease.

[0029] 2. The thickness of the wood square sawn out is 6 cm, and the bark tri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com