Novel skylight glass assembly for automobile

A sunroof and glass technology, applied in the field of new-type automotive sunroof glass assemblies, can solve the problems of high process requirements, large tolerances, and high PU material prices, and achieve the advantages of simple assembly process, improved appearance, improved product stability and service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

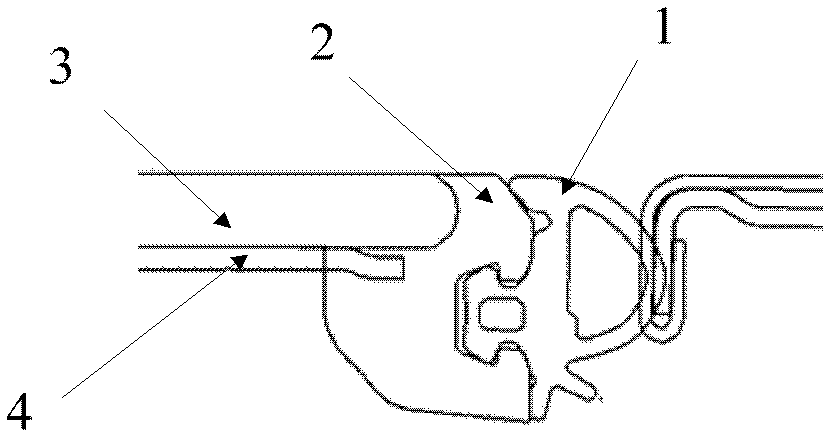

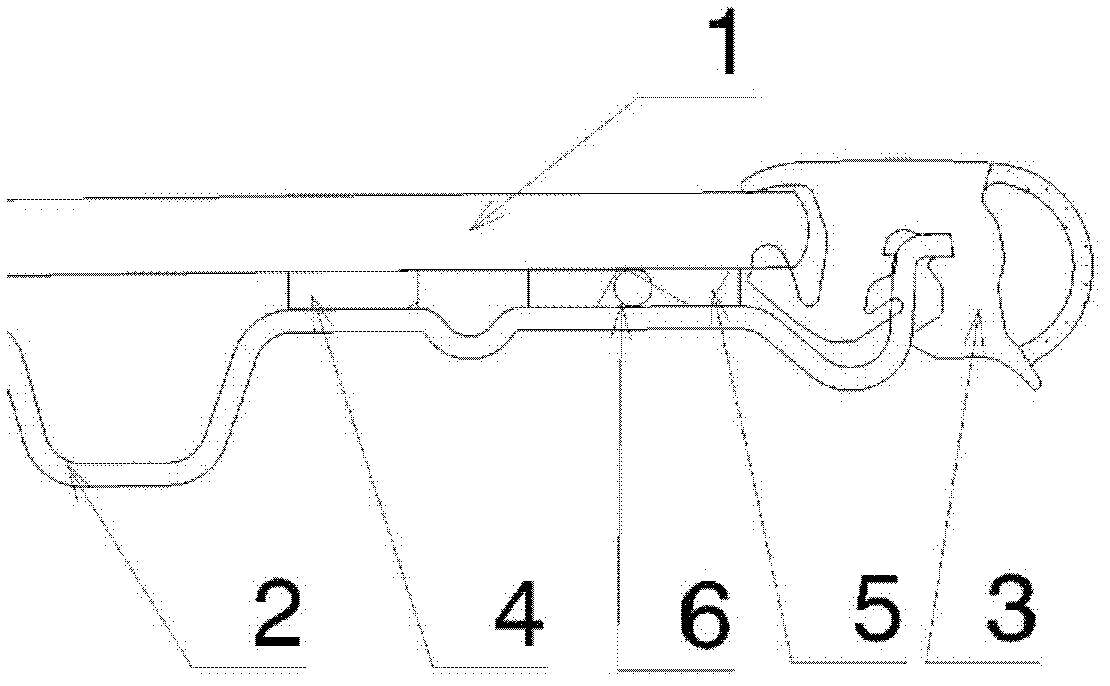

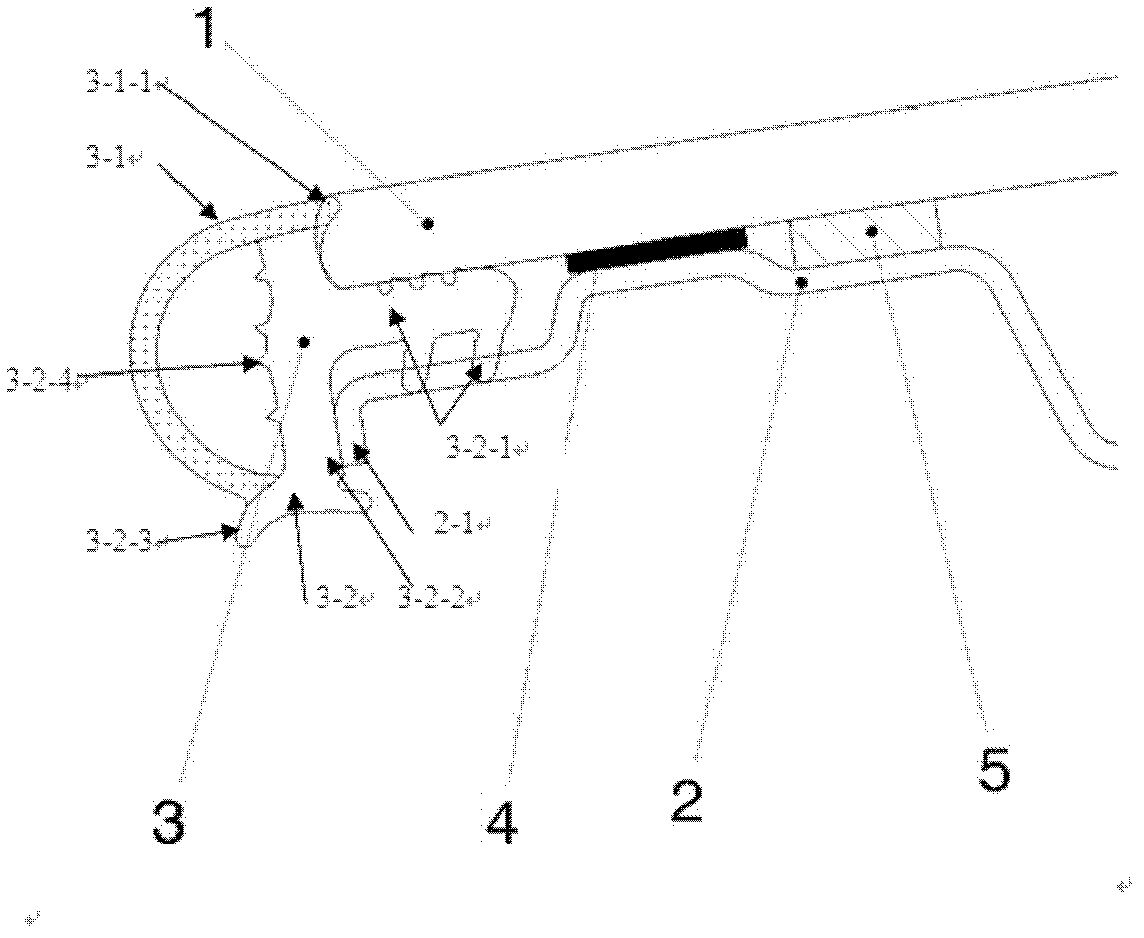

[0022] Such as image 3 As shown, the novel automobile sunroof glass assembly of the present invention comprises sunroof glass (1), sunroof glass frame (2), sunroof sealing strip (3), 3M tape (4) and cold glue (5), wherein the sunroof glass (1) is connected and fixed with the skylight glass frame (2) by 3M adhesive tape (4) and cold glue (5).

[0023] The sunroof glass frame (2) is used to connect the moving structure to realize the movement of the sunroof glass assembly; the sunroof sealing strip (3) is used to seal between the roof of the car and the sunroof glass, preventing a large amount of water from entering the compartment and protecting the edge of the glass at the same time , plays a buffer role in motion. The skylight glass (1) and the skylight glass frame (2) are connected and fixed with 3M adhesive tape (4) and special cold glue (5), among which the 3M adhesive tape (4) is used for initial local fixation, during the cold glue solidification process To ensure the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com