Network-side circuit of electric locomotive unit

An electric locomotive and side circuit technology, applied in the field of rail transit, can solve the problems of large power loss of the whole vehicle, low availability of the whole vehicle, and the inability of the grid side circuit to meet heavy load and high power traction, so as to achieve small power loss and improve the efficiency of the whole vehicle. The effect of usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

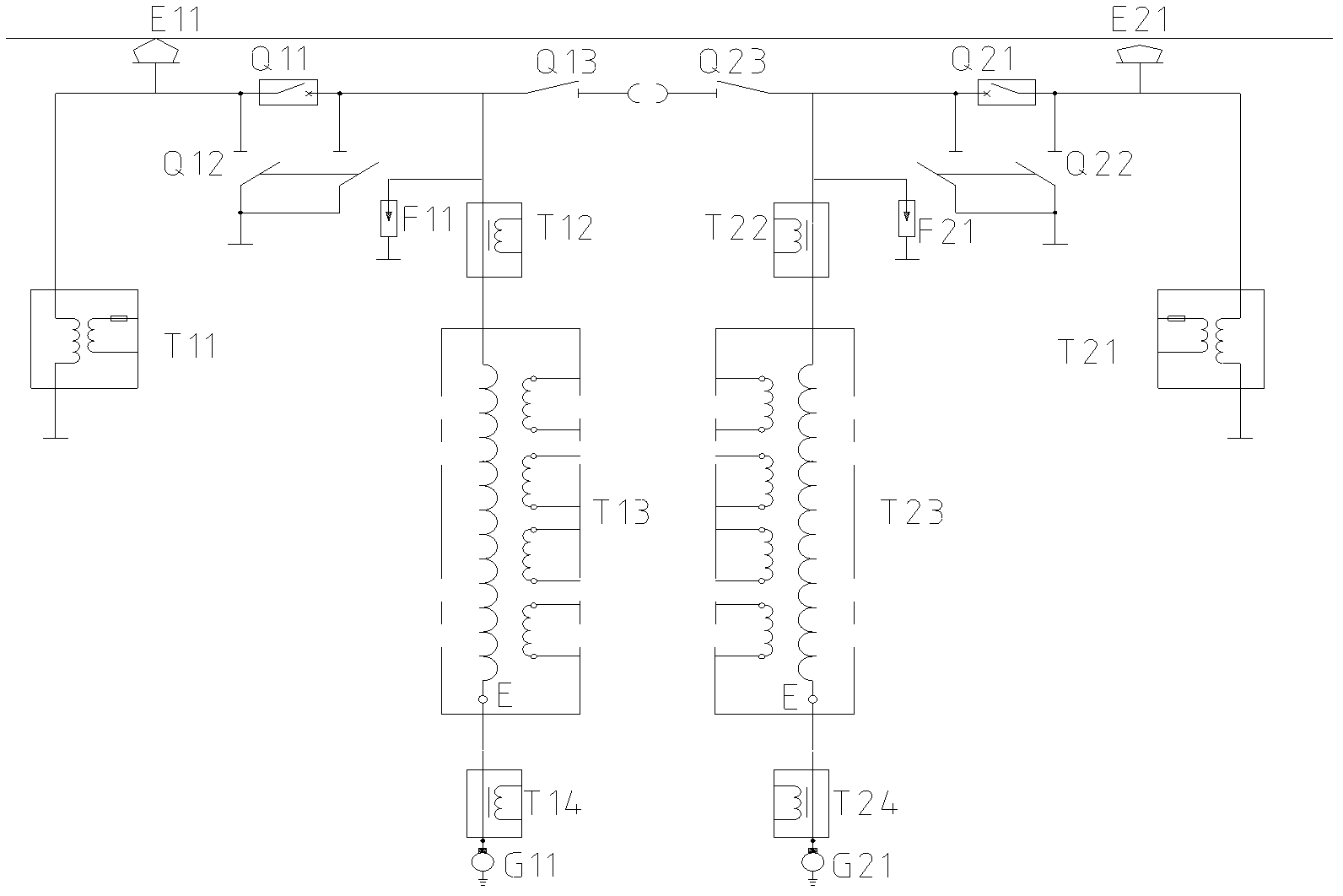

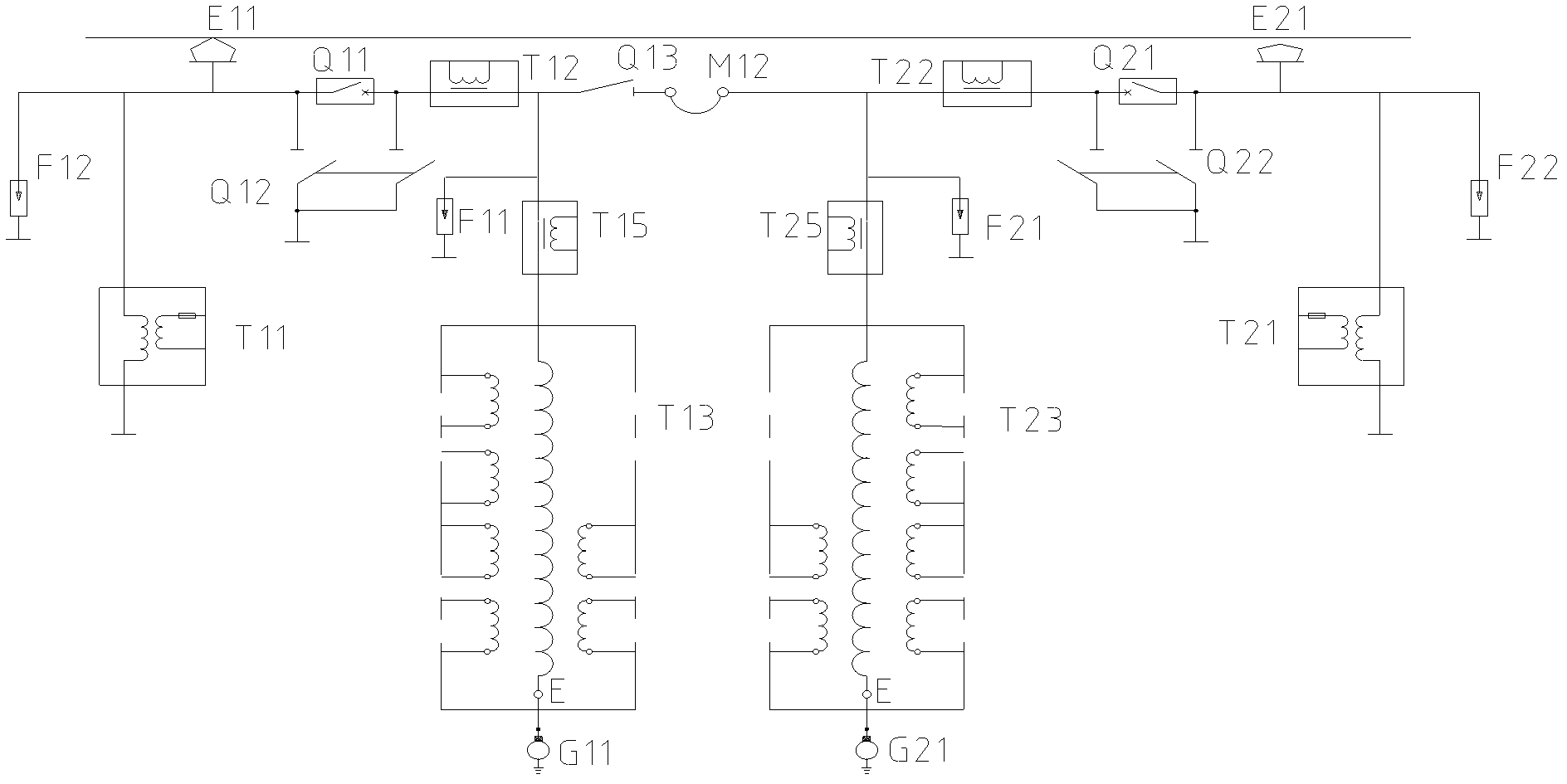

[0022] Figure 4 The circuit shown is an electric locomotive grid-side circuit structure provided by an embodiment of the present invention. It consists of two sets of grid-side circuits with pantographs and a set of grid-side circuits without pantographs to form a three-node power grid. The grid-side main circuit of the locomotive group, the first and third groups are grid-side circuits of electric locomotives with pantographs, and the second group is grid-side circuits of electric locomotives without pantographs. The first and third groups of electric locomotive grid side circuits include high voltage voltage transformer T11 / T31, pantograph E11 / E31, high voltage isolating switch Q13 / Q23 / Q31 / Q32, main circuit breaker Q11 / Q33, grounding switch Q14 / Q34, primary side high-voltage current transformer T12 / T32, transformer T13 / T33, primary side grounding current transformer T14 / T34, shaft end grounding device G11 / G31; the second group of electric locomotive network side circuit in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com