Logistics process for production, inventory and sale links of finished cigarettes

A tobacco finished product and process technology, which is applied in the field of logistics technology in the production, storage and sales of finished tobacco products, can solve the problems of affecting the effective operation rate of finished products, wasting resources, and poor data confidentiality, so as to reduce equipment management and maintenance costs and improve system operation. Stable and reliable, easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

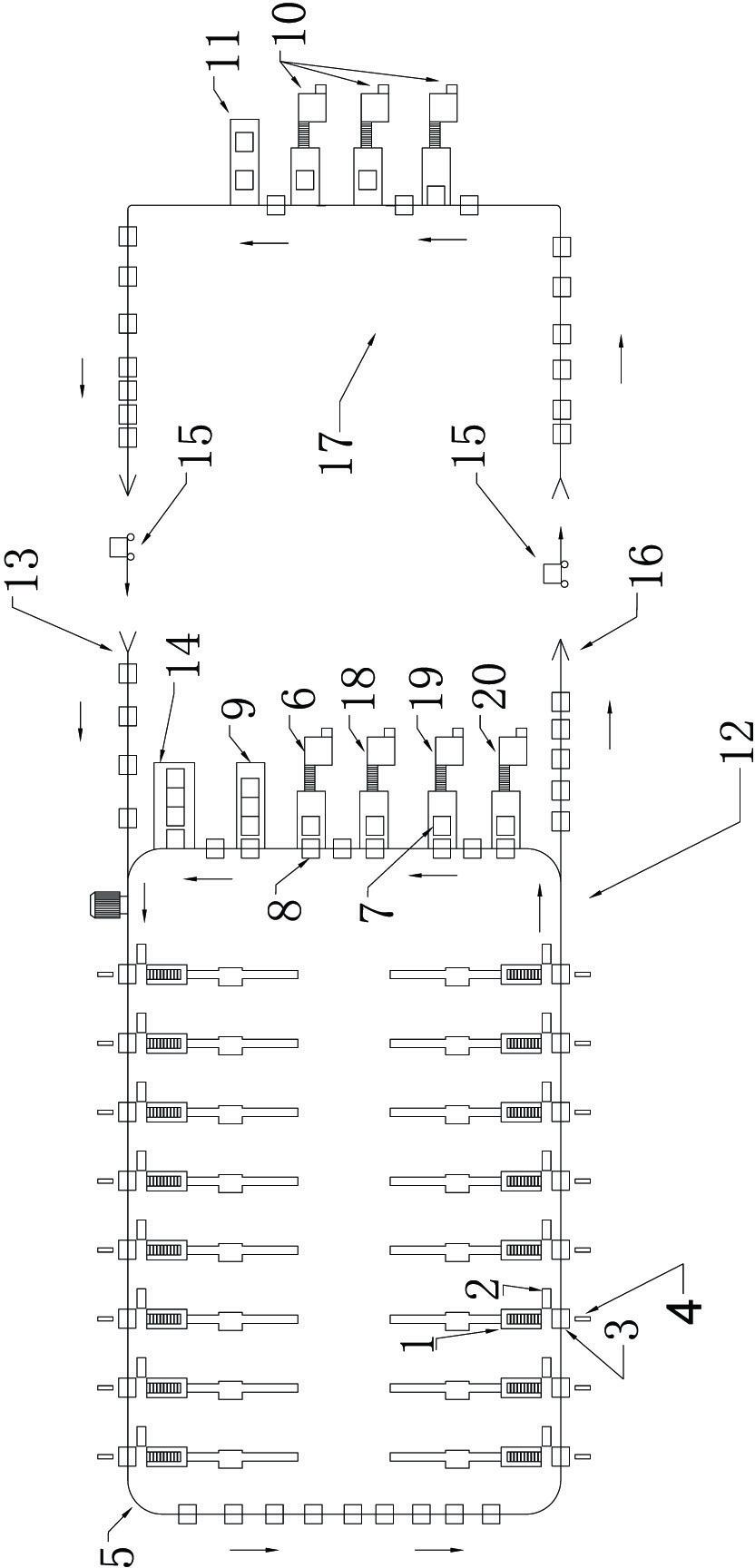

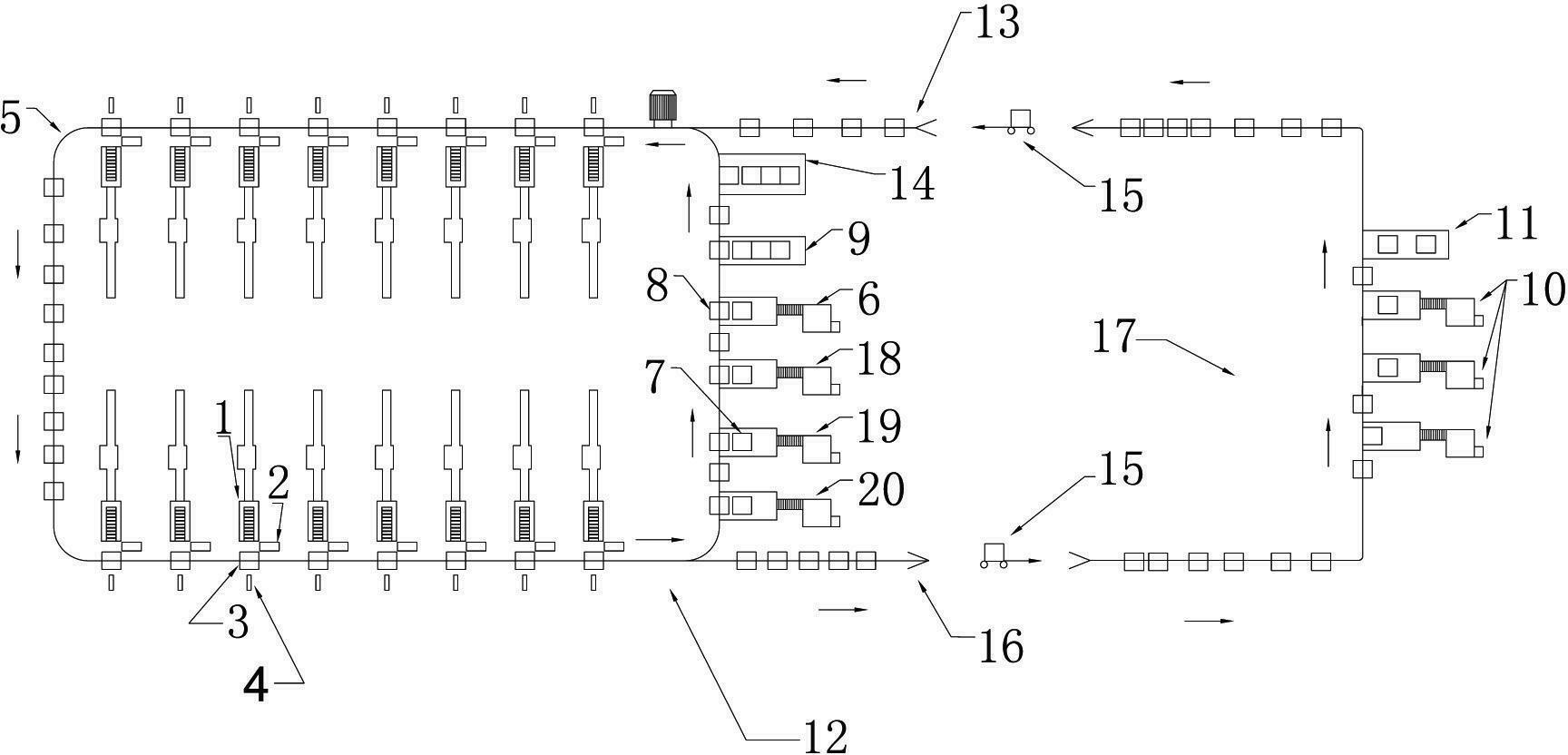

[0031] The present invention will be further described below in conjunction with specific examples.

[0032] See attached figure 1As shown, the logistics process in the production, storage and sales link of finished cigarette products described in this embodiment includes the following steps: first, the finished cigarette products at the exit of the finished cigarette packaging machine 1 are driven by the mechanical loading device 2 and automatically loaded into the pre-positioned low-positioned cigarettes. Opened empty foldable plastic turnover box 3, and the foldable plastic turnover box 3 is provided with RFID information identification card, while the cigarettes are packed in the box, the RFID read-write head 4 of the electronic control system checks the destination, etc. Write the information into the RFID information identification card in the foldable plastic turnover box 3, and lift the foldable plastic turnover box 3 to the elevated loop conveyor line 5, and send it t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com