Melt method granulation equipment for high density urine base composite fertilizer

A technology of urea-based compound fertilizer and granulation equipment, which is applied in the direction of fertilizer form, fertilization device, fertilizer mixture, etc., and can solve the problems of large investment, long process and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

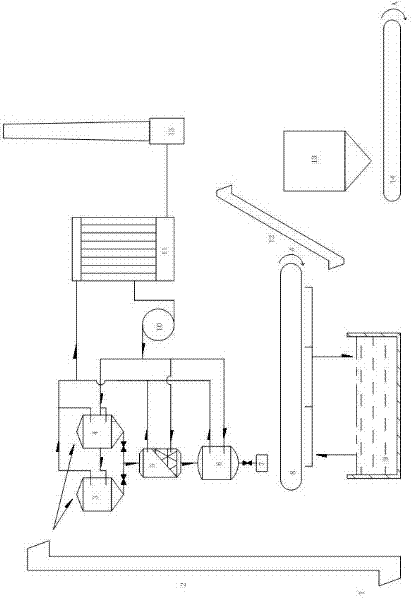

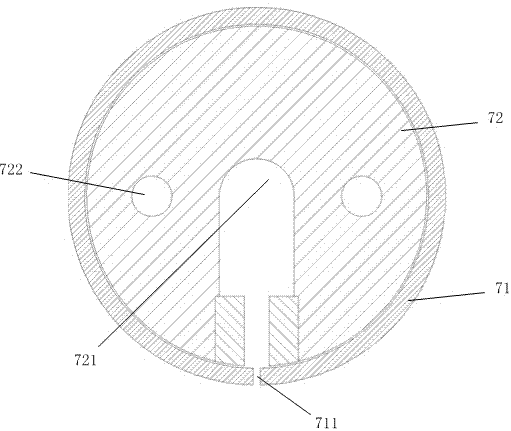

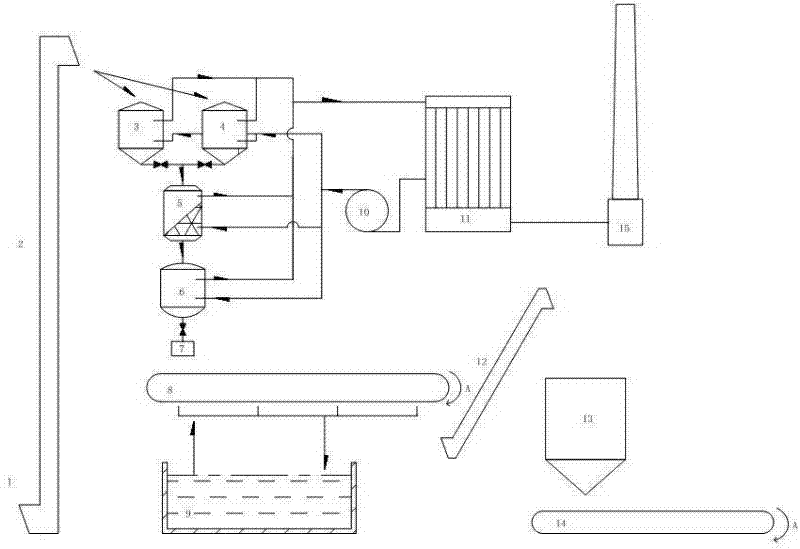

[0019] figure 1 , figure 2 Shown is the preferred embodiment of the granulation equipment of the high-concentration urea-based compound fertilizer of the present invention. like figure 1 As shown, the granulation equipment of the high-concentration urea-based compound fertilizer of the present embodiment mainly includes two melting kettles 3, 4, a shear filter 5, a buffer storage tank 6, a distributor 7 and a rotary steel belt condensation granulator 8. The outlets of the two melting kettles 3 and 4 are insulated with the shear filter 5, and the outlet of the shear filter 5 is connected with the buffer storage tank 6 for insulation, and the outlet of the buffer storage tank 6 is connected with the distributor 7. Insulation connection; a rotary steel belt condensing granulator 8 is provided below the distributor 7, and a cooling water nozzle and a corresponding water tank 9 are provided under the steel belt of the rotary steel belt condensing granulator 8. A packaging syst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com