Method for preparing polyamine-epichlorohydrin color fixing agent

A technology of epichlorohydrin and color-fixing agent, applied in the field of textile dyeing and finishing, can solve problems such as poor color-fixing effect, and achieve the effect of maintaining the feel of fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

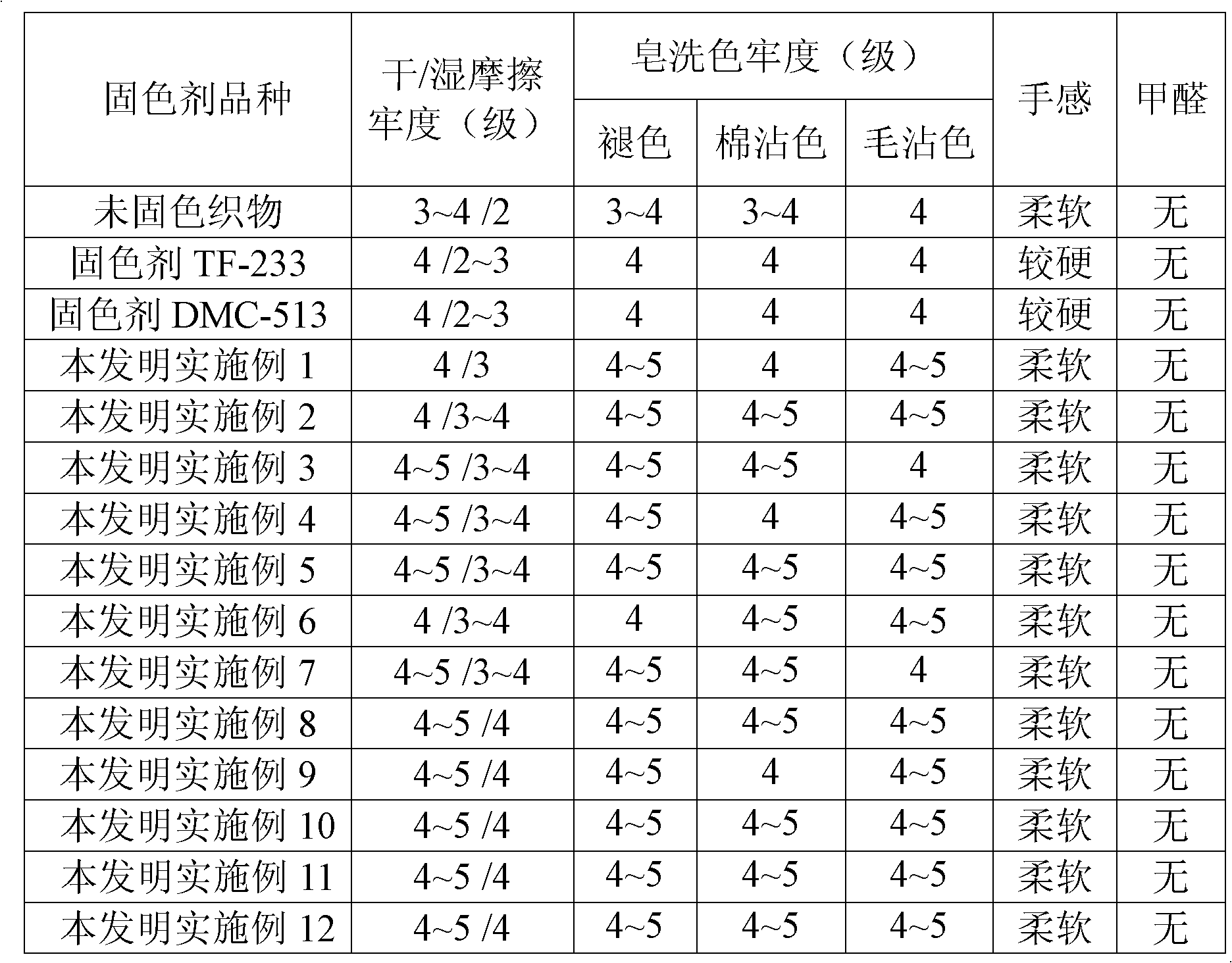

Examples

preparation example Construction

[0018] The preparation method of polyamine-epichlorohydrin color fixing agent of the present invention, specifically implement according to the following steps:

[0019] Option One:

[0020] Step 1: Weighing triethylenetetramine, epichlorohydrin, triethylamine and distilled water respectively according to the molar ratio of 1-3:6-10:1-3:20-40.

[0021] Step 2: Put the triethylenetetramine weighed in step 1 into the reactor, turn on the agitator, add the distilled water weighed in step 1, add the epichlorohydrin weighed in step 1 dropwise using a constant pressure dropping funnel, and control the drop Add the speed to keep the temperature in the reactor at 15-20°C. After the dropwise addition, keep it warm for 1h, then add the triethylamine weighed in step 1, control the reaction temperature at 15-20°C for 1h, and then gradually increase the temperature Heat to 60-65°C, keep warm for 4-5 hours, cool to room temperature and discharge.

[0022] Alternatively, add the triethylen...

Embodiment 1

[0033]Put 0.2 mol of triethylenetetramine into the reactor, start the agitator, add 4 mol of distilled water, add 1.2 mol of epichlorohydrin dropwise through a constant pressure dropping funnel, and control the rate of dropping to keep the temperature in the reactor at 15~ Insulate and react at 20°C for 1h, then add 0.2mol of triethylamine dropwise, control the reaction temperature at 15-20°C for 1h, then gradually raise the temperature to 60-65°C, keep warm for 4-5h, then cool to room temperature After discharge.

Embodiment 2

[0035] Put 0.4 mol of triethylenetetramine into the reactor, start the agitator, add 6 mol of distilled water, add 1.6 mol of epichlorohydrin dropwise through a constant pressure dropping funnel, and control the rate of dropping to keep the temperature in the reactor at 15~ Insulate and react at 20°C for 1h, then add 0.4mol of triethylamine dropwise, control the reaction temperature at 15-20°C for 1h, then gradually raise the temperature to 60-65°C, keep warm for 4-5h, then cool to room temperature After discharge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com