High precision internal combustion bolt spanner

An internal combustion bolt, high-precision technology, applied in the direction of track, gear transmission, track maintenance, etc., can solve the problems of low efficiency, achieve the effect of high operating strength, precise torque adjustment, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

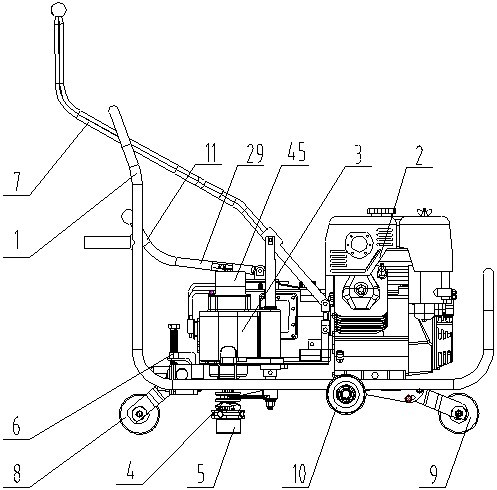

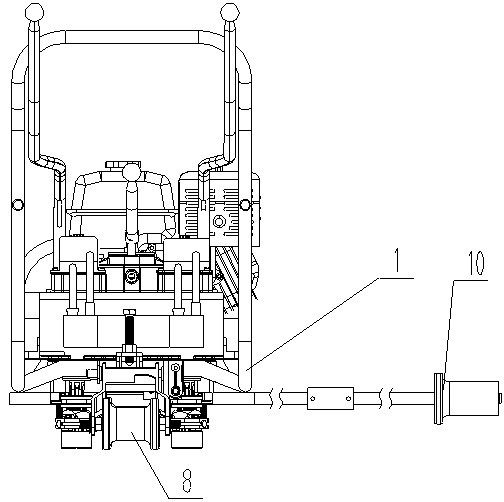

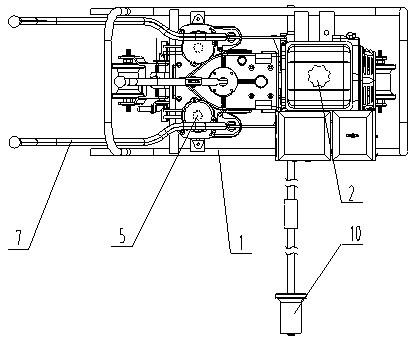

[0029] The structure of the high-precision internal combustion bolt wrench of the present invention is described in detail below in conjunction with the accompanying drawings:

[0030] Such as figure 1 , figure 2 , image 3 Shown: the high-precision internal combustion bolt wrench of the present invention includes a frame 1 on which an internal combustion engine 2, a speed change device 3, a quill shaft 4, a sleeve 5, a sleeve height adjustment mechanism 6 and a sleeve manipulation mechanism are arranged 7. The front traveling wheel 8, the rear traveling wheel 9 and the auxiliary support shaft 10 are arranged under the frame 1. The wrench rides on a steel rail through the front traveling wheel 8 and the rear traveling wheel 9, and is supported by the supporting shaft 10 on the other side. One rail track forms a stable support; when working, push the frame 1, which can walk on the two rails in a balanced manner.

[0031] The high-precision internal combustion bolt wrenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com