Split self-excited serial electric-cyclone gas-solid separating device of circulating fluidized bed boiler

A technology of circulating fluidized bed and cyclone separator, which is applied in the direction of swirling device, fluidized bed combustion equipment, fuel burning in molten state, etc., to achieve improved stability and safety level, simplified mechanism, and increased discharge voltage level Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

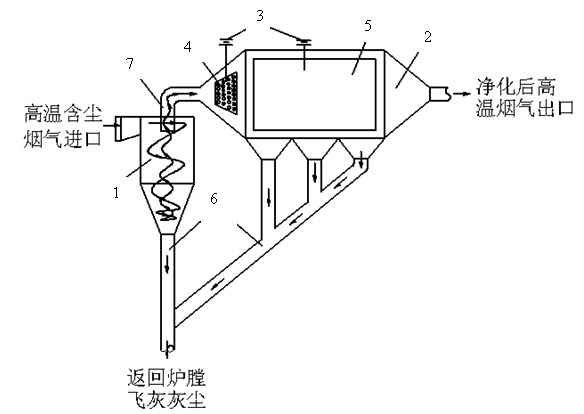

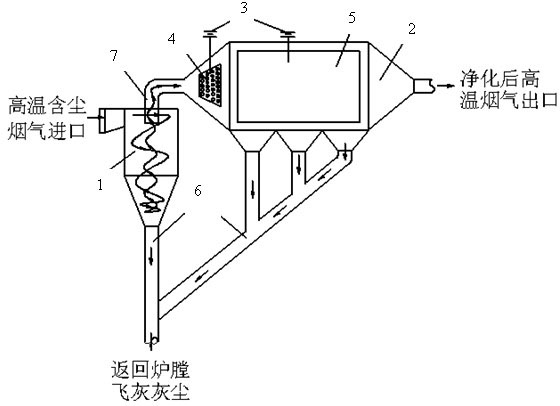

[0026] Combine below figure 1 To further explain the present invention:

[0027] Such as figure 1 As shown, the split self-excited serial power-cyclone separation device of the circulating fluidized bed boiler of the present invention includes a high-temperature cyclone separator 1, a power gas-solid separator 2, a DC power supply 3, an emitter plate 4, a dust collecting plate 5. The ash drop channel 6 and the flue gas discharge tube 7 are composed of. The upper part of the cyclone separator 1 is provided with a flue gas discharge tube, and the lower end of the cyclone separator is a fly ash return pipe 6. The electric gas-solid separator includes a shell, an emitter plate 4 and a dust collecting plate 5. There are a flue gas inlet, a flue gas outlet and an ash outlet. The emitter plate is arranged inside the flue gas inlet, and the dust collecting plate is arranged at the upper end of the ash outlet; the flue gas inlet is connected to the flue gas discharge tube 7 , The dus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com