Accelerated degradation testing method for nitrile rubber O-shaped sealing ring based on step stress

An accelerated degradation test, O-ring technology, applied in measurement devices, instruments, mechanical devices, etc., can solve the problems of complex sequential stress application methods and difficult process control, saving test costs, effectively analyzing, reducing effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

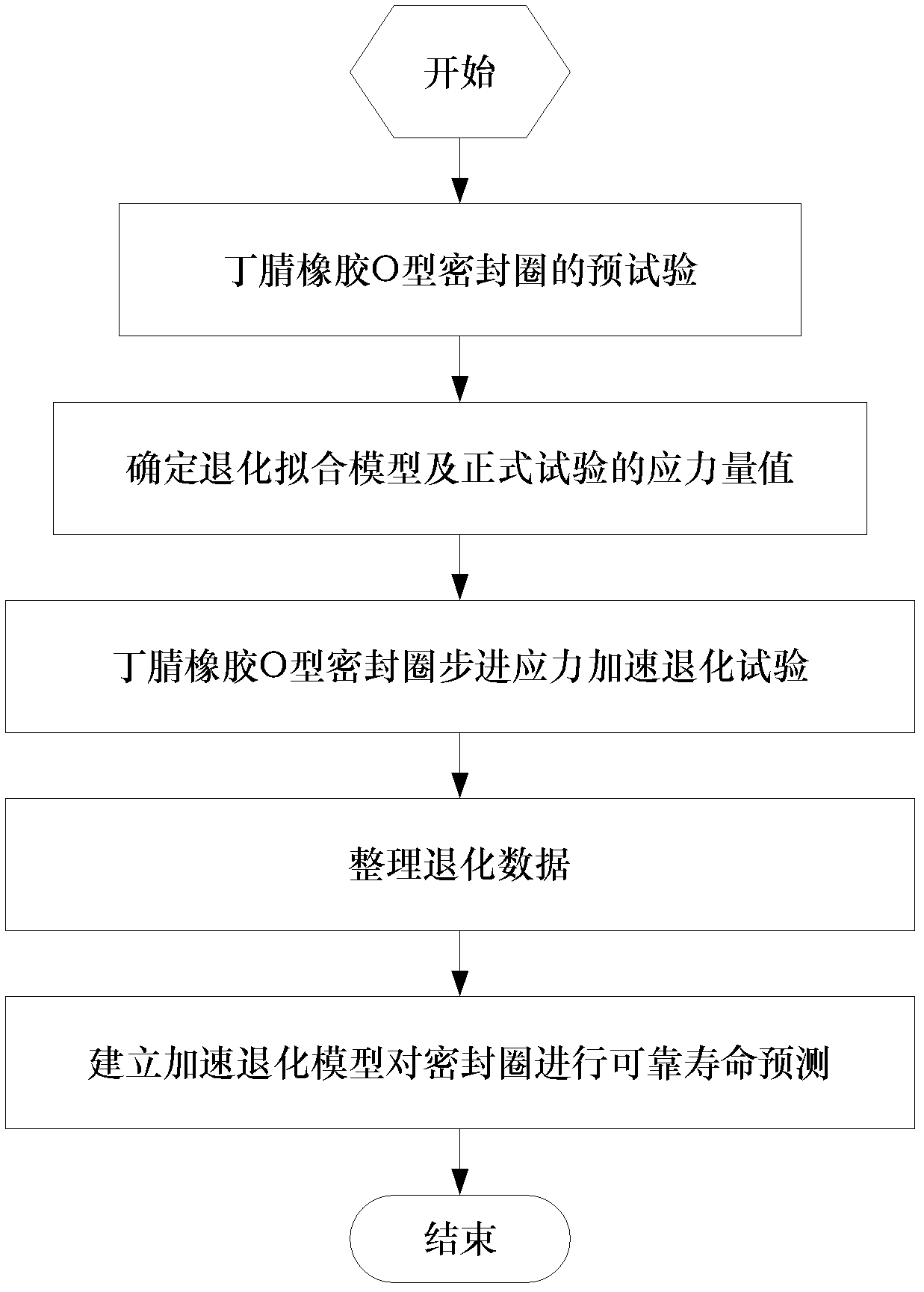

Method used

Image

Examples

Embodiment

[0086] The step stress accelerated degradation test was carried out on the nitrile rubber O-ring used in a certain type of electro-hydraulic steering gear system. The pre-test sample size was 6, the formal test sample size was 12, and the 4 temperature stress levels were 70°C , 80°C, 90°C, 100°C, the test time is 79 days, the number of measurement points is 13 at 70°C, 16 at 80°C, 17 at 90°C, and 14 at 100°C. It was tested as described above.

[0087] Step 1, pre-test of nitrile rubber O-ring;

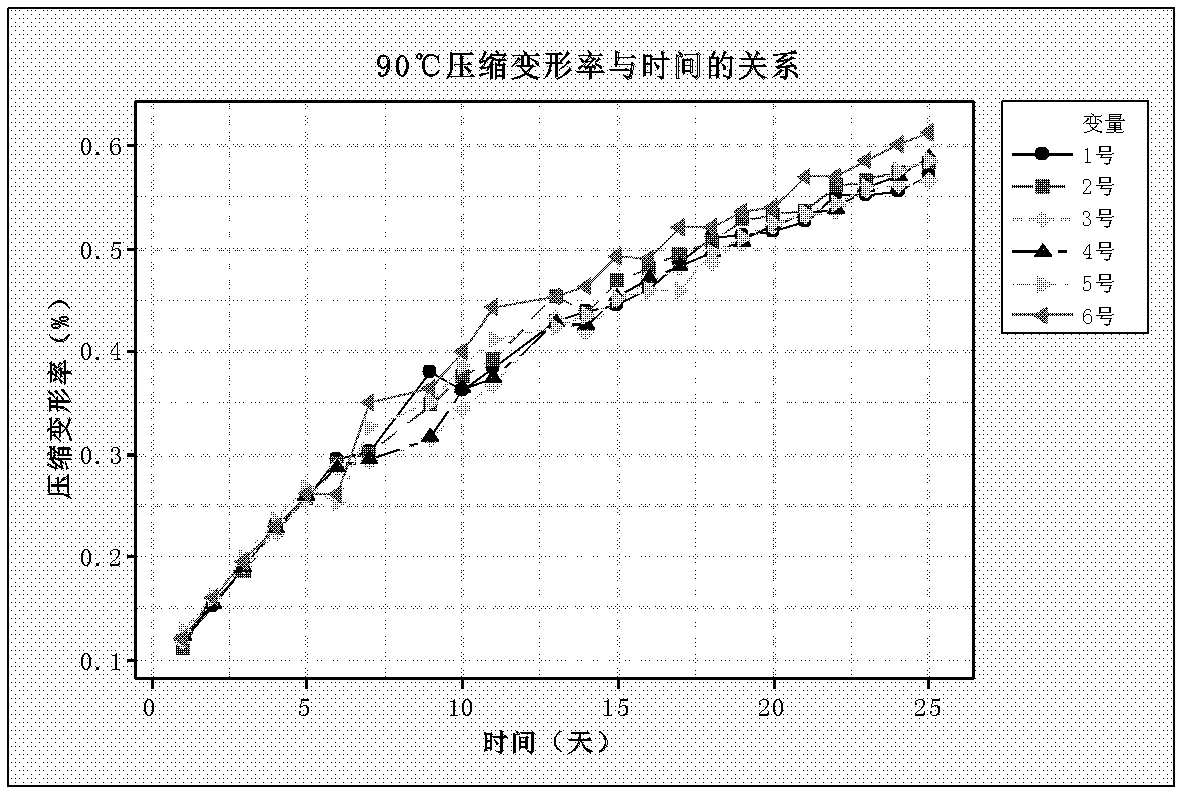

[0088] Select 90°C as the accelerated stress, put six rubber rings into the constant temperature accelerated test, and measure the thickness change of the rubber once a day. The obtained degradation data of 6 samples are as figure 2 shown.

[0089] Step 2, determining the stress value of the degradation fitting model and the formal test;

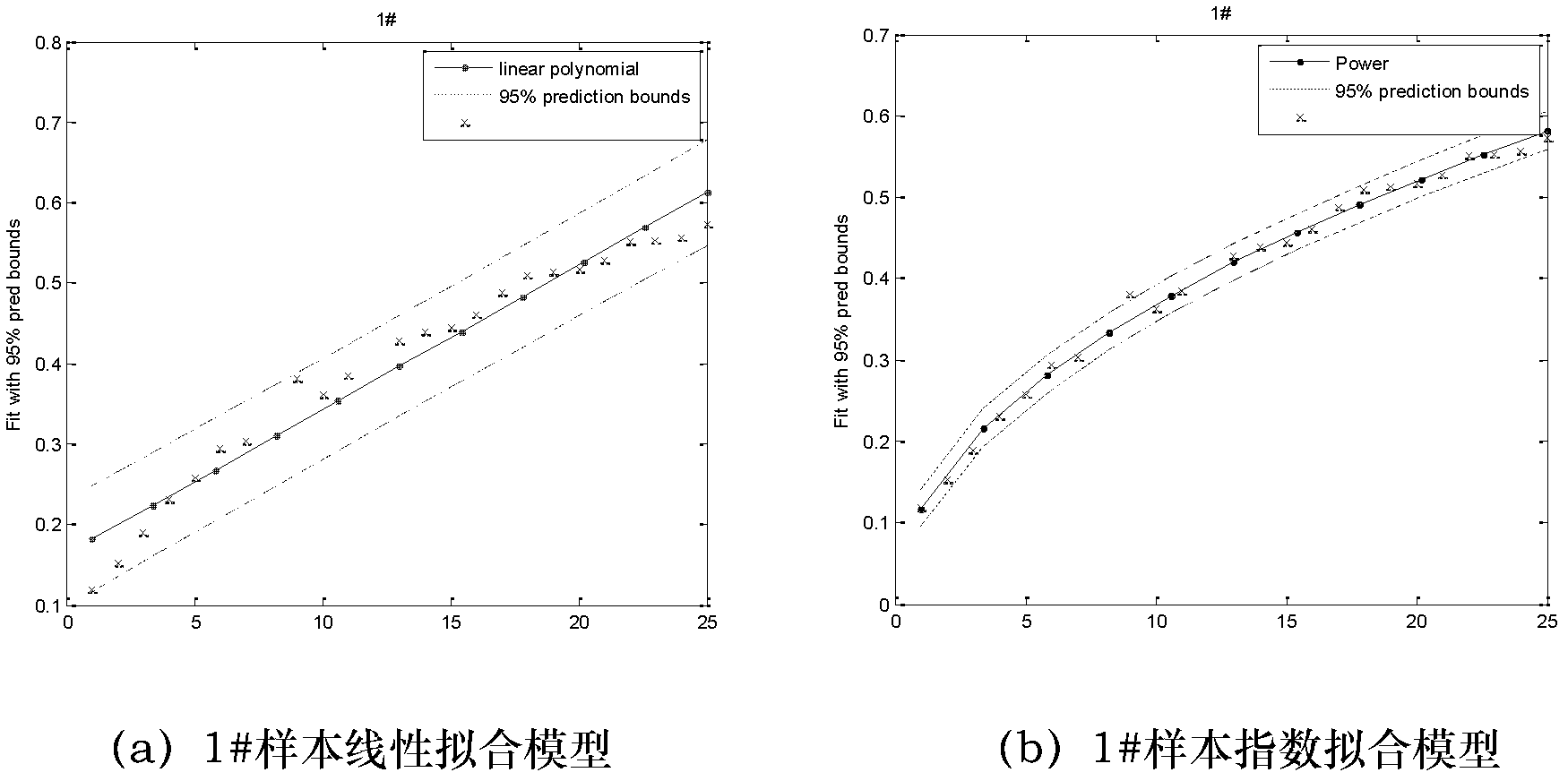

[0090] Use different data models to fit the results of the pre-test, and select the one with the best fitting effect. Specific as Figure 3 ~...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com