Device and method for detecting movement state of load-bearing steel wire rope

A detection device, a technology of motion state, applied in the direction of measuring device, indication/recording action, speed/acceleration/impact measurement, etc., can solve the problems of inability to accurately measure the longitudinal motion state of the wire rope, evaluation, and no wire rope detection device and method , to achieve the effect of overcoming the problem that the twisting state cannot be measured, accurate measurement, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

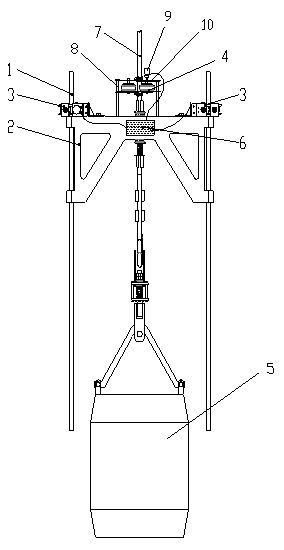

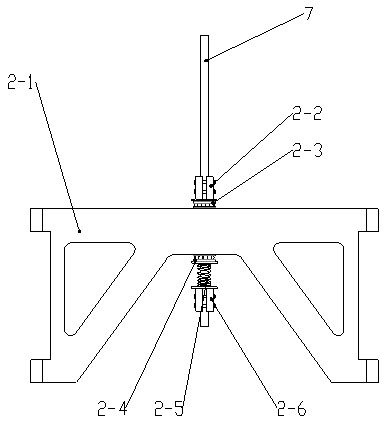

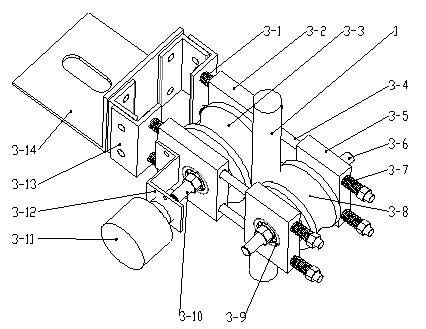

[0020] The steel wire rope motion state detection device of the present invention mainly consists of a guide rope 1 for longitudinal motion state detection, a signal collector 6, a carriage device 2 that moves along the guide rope 1, and is fixed on the carriage device 2 and moves along the guide rope 1. Sliding longitudinal motion detection device 3, twist detection device 4 fixed on the carriage 2 and clamped on the detection wire rope 7, and a counterweight device 5 fixed at the end of the detection wire rope 7 constitute. The carriage device 2 includes a carriage 2-1, two upper and lower steel wire rope clamping blocks 2-2, 2-6 arranged on the carriage 2-1, and upper and lower clamping blocks 2-2, 2-6. There are upper and lower thrust bearings 2-3, 2-4 between 6 and the carriage 2-1, and a preload spring 2-5 between the lower clamping block 2-6 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com